Introducing the vacuum transistor: a device made from emptiness

- Transfer

A curious mixture of an electron tube and a MOSFET may one day replace traditional silicon.

In September 1976, at the height of the Cold War, Viktor Ivanovich Belenko , a Soviet pilot and defector, deviated from the course of a training flight over Siberia, which he spent on the MiG-25P, quickly crossed the Sea of Japan at low altitude, and landed the plane in a civilian airport Hokkaido, when the fuel was only 30 seconds. His sudden betrayal of the Motherland became manna from heaven for American military analysts, who for the first time had the opportunity to study a high-speed Soviet fighter close by, which they considered to be one of the most advanced aircraft. But what they saw amazed them.

The hull of the aircraft was made rougher than that of modern American fighter jets, and mainly consisted of steel, not titanium. Instrument compartments were filled with equipment that worked on electronic tubes, and not transistors. The obvious conclusion, despite the prevailing fears, was that even the most advanced technology was hopelessly behind Western technology.

Indeed, in the United States electron tubes [which they call vacuum tubes / approx. transl.] gave way to smaller and power-consuming solid-state devices two decades before, shortly after William Shockley, John Bardeen and Walter Brattein assembled the first transistor at Bell Laboratories in 1947. By the mid-1970s, electronic tubes in Western electronics could be found only in various types of special equipment - not counting the huge number of cathode-ray tubes of televisions. Today they have disappeared, and out of the few niches the electron tubes have practically become extinct. Therefore, it may surprise you that some modest changes in the process of manufacturing integrated circuits can breathe life back into vacuum electronics.

We are at the Ames Research Center.NASA has been developing vacuum channel transistors for the last few years. Our research is still at an early stage, but the prototypes made by us demonstrate extremely promising prospects for these innovative devices. Transistors with a vacuum channel can operate 10 times faster than conventional silicon, and may be able to operate at terahertz frequencies that have long been outside the capabilities of any solid-state device. They also tolerate high temperatures and radiation much more easily. To understand why this is so, you should understand the creation and operation of good old electronic tubes .

The descendant of the incandescent lamp. Electron tubes were the natural result of the development of incandescent bulbs, the development of which was actively pursued after the research of Thomas Edison, who studied the possibilities of radiation of electrons by heated filaments. The photo shows an early example of the Audion lamp from 1906, which strongly resembles an incandescent lamp, although the thread in this lamp is not visible - it has already burned for a long time. The thread worked as a cathode, from which the electrodes flew towards the anode or plate, located in the center of the glass tube. The current from the cathode to the anode could be controlled by varying the voltage applied to the grid — a zigzag wire that can be seen under the plate.

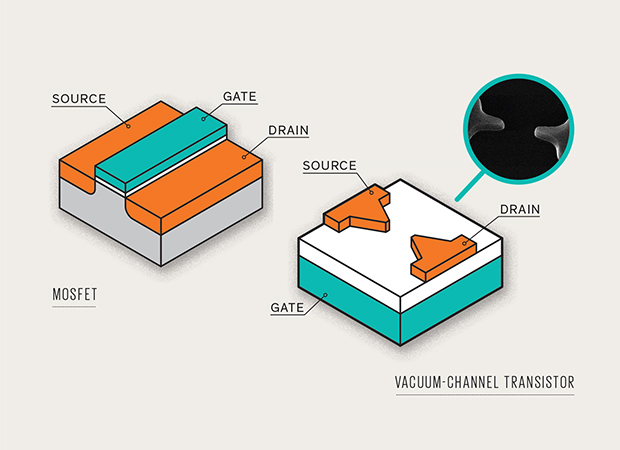

Finger-sized electronic tubes that amplified signals in countless radio and television receivers in the first half of the 20th century may look completely different from metal oxide semiconductor field effect transistors (MOSFETs or MOSFETs) that regularly hit us with their capabilities in modern digital electronics. But they are much alike. First, they are both three-contact devices. The voltage applied to one contact - the grid at a simple electron tube-triode or the gate of the transistor - controls the amount of current passing between the other contacts: from the cathode to the anode at the electron tube and from the source to the drain in the MOSFET. This ability allows these devices to operate as amplifiers or as switches.

However, the electric current in the electron tube flows completely differently than in the transistor. Electron tubes work due to thermionic emission : heating the cathode causes it to throw electrons into the surrounding vacuum. The current in the transistors is due to the diffusion of electrons (or holes, places where there is not enough electron) between the source and drain through the solid semiconducting material separating them.

Why did the electron tubes so long ago give way to solid-state electronics? Among the advantages of semiconductors - low cost, much smaller size, much longer lifetime, efficiency, reliability, durability and constancy. But with all this purely as a medium for the transfer of charge, the vacuum wins over semiconductors. Electrons easily propagate in the vacuum vacuum, and in atoms of a solid they experience collisions (scattering on a crystal lattice). Moreover, the vacuum is not susceptible to damage due to radiation, which affects semiconductors, and also produces less noise and distortion than solid materials.

The disadvantages of electronic tubes are not so annoying if you need only a small number of them to assemble a radio or television. However, in more complex schemes, they showed themselves from the worst side. For example, in the 1946 ENIAC computer there were 17,468 lamps, it consumed 150 kW of energy, weighed more than 27 tons and occupied almost 200 m 2 of space. And constantly broke - every day or two another lamp failed.

The chip in the bottle: the simplest electronic lamp capable of amplification is a triode, so named because it has three electrodes: a cathode, an anode, and a grid. Usually this structure has cylindrical symmetry when the cathode is surrounded by a grid, and the grid is surrounded by an anode. Its operation is similar to the operation of a field-effect transistor — the voltage applied to the grid controls the current between two other electrodes. Triode lamps often had five contacts to accommodate two additional electrical contacts for a heated wire.

The transistor revolution did away with these problems. However, the change in electronics occurred mainly because semiconductors had some special advantages, but because engineers were able to mass-produce and combine transistors into integrated circuits due to chemical engraving, or etching, of silicon substrates in order to obtain the desired pattern. . With the development of integrated circuit technology, they managed to push more and more transistors onto microchips, which allowed the circuits to become more and more complex with each generation. Also, electronics became faster, not becoming more expensive.

This speed advantage exists because the transistors became smaller, the electrons inside them had to travel shorter distances from the source to the drain, which allowed them to quickly turn on and off each transistor. Electron tubes were large and bulky, they had to be made separately on the machines. And although they improved over the years, they had nothing like the beneficial effects of Moore's law.

However, after four decades of compressing the size of transistors, we came to the conclusion that the oxide layer, an insulating gate in a typical MOSFET, reached only a few nanometers thick., and only a few tens of nanometers separate the source and drain. Conventional transistors will not be able to do much less. And the search for faster and more energy-efficient chips continues. What will be the next transistor technology? There is an intensive development of nanowires , carbon nanotubes and graphene. Perhaps one of these approaches will save the electronic industry. Or all will be zilch.

We are developing another candidate to replace the MOSFET, one with which researchers have periodically been busy for many years: a transistor with a vacuum channel. This is the result of a cross between a traditional electronic lamp and modern semiconductor manufacturing technologies. This curious mix combines the best properties of electron tubes and transistors, and can be made as small and cheap as any solid state device. It is the ability to make them in a small size that eliminates the well-known disadvantages of electronic tubes.

Transistor from an electron tube: transistors with a vacuum channel are very similar to metal oxide semiconductor, MOSFET (left). In a MOSFET, the voltage applied to the gate generates an electric field in the underlying semiconductor. This field draws charge carriers into the channel between the source and drain, allowing current to flow. No current flows to the gate; it is isolated by a thin layer of oxide. The transistor with a vacuum channel, developed by the authors (right) also uses a thin oxide layer to isolate the gate from the cathode with the anode, having sharp ends to enhance the electric field.

In an electron tube, an electrical filament, similar to the filament in bulbs, is used to heat the cathode, which is sufficient for it to begin to emit electrons. Therefore, electron tubes need time to warm up, and because they use so much energy. And also therefore they so often burn out (often it happens because of microscopic leakage in glass). However, TCE does not need a filament or hot cathode. If the device is made small enough, then the electric field inside it will be enough to draw electrons from the source - this is called field emission . By eliminating energy-consuming heating elements, we reduce the space occupied by the device on the chip and make this new transistor energy efficient.

Another weak point of the electron tubes is that they need to maintain a deep vacuum, which is usually about 1/1000 of atmospheric pressure, in order to avoid the collision of electrons with gas molecules. At such low pressures, the electric field causes the positively charged residual gas ions to accelerate and bombard the cathode, creating sharp nanometer protrusions, because of which it degrades and eventually turns out to be destroyed.

These long-known problems of vacuum electronics can be overcome. What if the distance between the cathode and the anode is less than the average distance that an electron travels before colliding with a gas molecule - less than the average free path? Then you will not have to worry about collisions between electrons and gas molecules. For example, the average free path of electrons in air at normal pressure is 200 nm, which is quite a lot on the scale of modern transistors. If helium is used instead of air, the average free path will increase to 1 micron. This means that an electron passing through a gap 100 nm wide will collide with a gas with a probability of only 10%. Make the gap smaller, and the probability will decrease further.

But even with a low probability of collision, many electrons will still collide with gas molecules. If the blow knocks the bound electron out of the molecule, it will turn into a positively charged ion, and the electric field will send it towards the cathode. Due to the positive ion bombardment, the cathodes degrade. Therefore, this process should be avoided whenever possible.

Fortunately, at low voltage, electrons will never gain enough high energy to ionize helium. Therefore, if the dimensions of the vacuum transistor will be much smaller than the average free path of electrons (which is easy to achieve), and the operating voltage will be quite low (and this is not difficult to arrange), then the device will work fine at atmospheric pressure. That is, in this, nominally vacuum electronics of miniature size, there will be no need to maintain any vacuum at all!

And how to turn this new transistor on and off? At the electron tube-triode, we control the current flowing through it, changing the voltage applied to the grid — a grid-like electrode located between the cathode and the anode. If the grid is placed closer to the cathode, it will increase its electrostatic control, but it will also increase the amount of current flowing to the grid. Ideally, no current should flow to the grid at all, since this leads to energy losses and even lamp failure. But in practice, there is always a small current.

To avoid such problems, we control the current in TCEs in the same way as in a conventional MOSFET, using a gate electrode, which isolates it from the current with a dielectric material (silicon dioxide). The insulator transfers the electric field to where it is needed, preventing the current from flowing through the grid.

As you can see, a TCE is not a complicated device at all. It works much easier than any previous transistors.

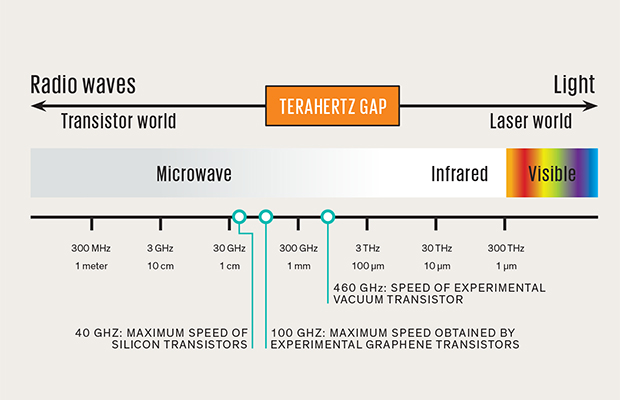

Although we are still in the early stages of our research, we believe that the recent improvements in TCEs will one day be able to seriously affect the electronics industry, in particular those areas of its application where speed is very important. In our very first attempt to manufacture a prototype, we got a device capable of operating at a frequency of 460 GHz - about 10 times more than the best silicon transistors. This makes TCEs a promising device for operation in the so-called. terahertz discontinuity - that part of the electromagnetic spectrum that is above microwaves and below the infrared range.

Filling the gap: TCEs promise to work at frequencies between microwave and infrared — this range of the spectrum is sometimes called the terahertz gap, since most semiconductor devices hardly work at such frequencies. Promising use cases include directional high-speed data transfer and tracking of hazardous substances.

Such frequencies, in the range of 0.1 to 10 THz, are useful for the recognition of hazardous substances and safe high-speed data transmission - and this is just a couple of examples. However, it is difficult to use terahertz waves, since conventional semiconductor devices cannot create or recognize such radiation. Vacuum transistors could fill this void, sorry for the pun. These transistors could be useful in future microprocessors, as the method of their production is fully compatible with the production of conventional chips. However, before this, it is necessary to solve several problems.

Our prototype TVK operates from 10 V, which is an order of magnitude greater than the voltage used by the microcircuits. However, researchers from the University of Pittsburgh have already been able to make TCEs operating from 1 or 2 V, although this required serious compromises in design flexibility. We are confident that we can reduce the voltage requirements to a similar level, reducing the distance between the cathode and the anode. The magnitude of their angle determines the concentration of the electric field, and the composition of the cathode material determines how strong the field is required to extract electrons from it. Therefore, we may be able to reduce the voltage by picking up electrodes with sharper tips or a more suitable chemical compound that reduces the barrier that electrons overcome when running away from the cathode. This will be the job of finding a balance, since the changes that lead to a decrease in the operating voltage,

The next big stage is to create a large number of TCEs by placing them on an integrated circuit. To do this, we plan to use many existing tools for development using a computer and software for simulating the operation of integrated circuits. But before that we will need to clarify our computer models of new transistors, and develop rules for connecting a large number of them. We will also need to develop suitable packaging methods for these devices with a pressure of 1 atm filled with helium. Most likely, for this it will be possible to apply the technologies used for the packaging of microelectromechanical sensors - accelerometers and gyroscopes without special problems.

Of course, there is still a lot of work to be done before we can begin commercial production of the product. But when this happens, a new generation of vacuum electronics will surely boast unexpected possibilities. You should expect this, otherwise you may be in the place of military analysts who studied the Soviet MiG-25 in Japan in 1976: they later realized that vacuum tubes could withstand the electromagnetic impulse generated by a nuclear explosion, better than any Western aircraft. And only then could they recognize the value of a small amount of nothing.