Guikporn wristwatch quartz watches "Ray" - and a bit of overclocking

Some things to which we are quite accustomed, and sometimes we consider it very outdated and simple - on closer inspection it can be much more complicated than it seems.

Some things to which we are quite accustomed, and sometimes we consider it very outdated and simple - on closer inspection it can be much more complicated than it seems. In my opinion, the most unexpectedly complex, albeit seemingly outdated things are quartz watches and film cameras. Available made them hundreds of years of development of world industrial production and many billions spent on R & D.

Quartz watch this time we will do. As a patient - a Belarusian-made wristwatch, which was presented to me in immemorial times.

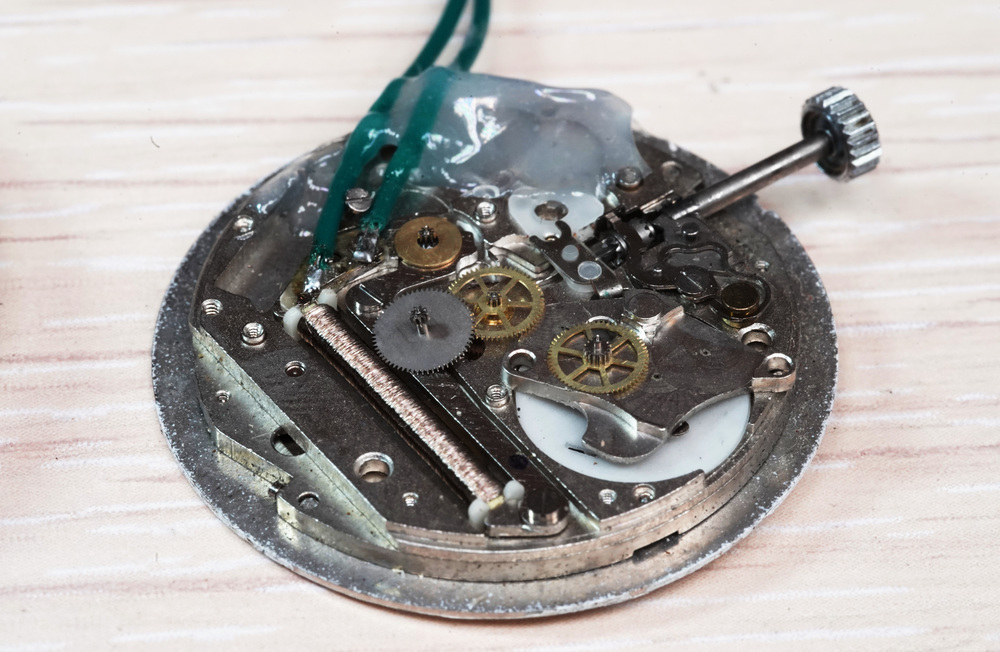

The watches themselves look simple and ascetic. The wires are already my self-activity, the results of which will be at the end of the article:

On the reverse side, we see a microchip that generates 0.5 Hz meander from 32768 Hz of quartz. The meander is fed to a coil with a wild number of turns (resistance 2.5 kΩ), which sets the mechanics in motion. Moving in both directions advances the hand for 1 second.

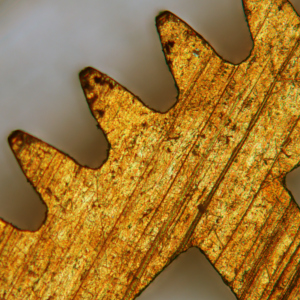

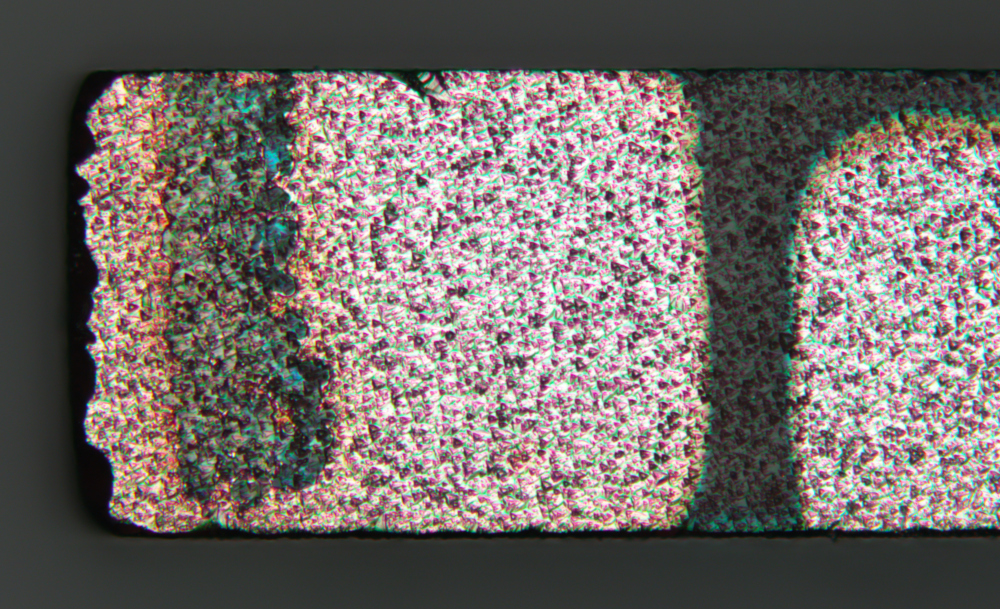

Nearer. Gear wheels with a step of 200 microns. Here they were probably squeezed out by a stamp, and the very squeak of technology was to cut them out by ion etching , using the same technology that MEMS produces:

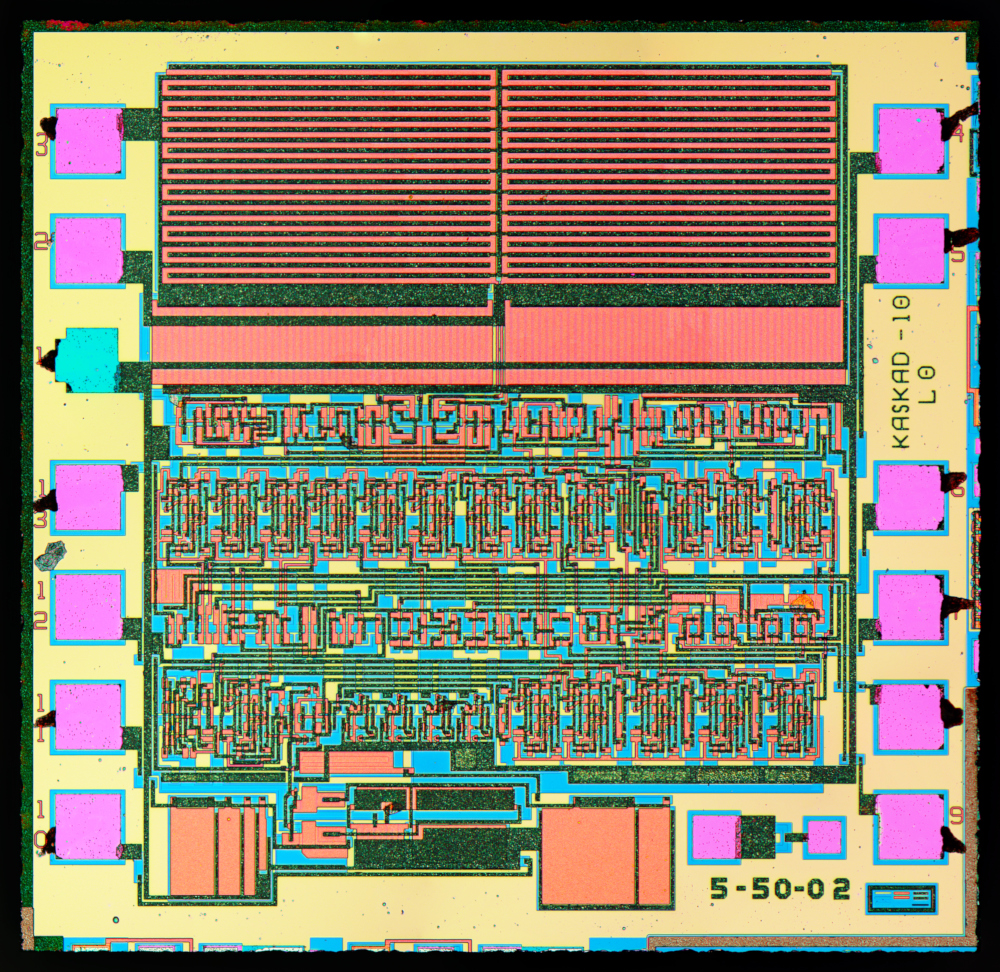

Of course, let's take a closer look at the microcircuit (clickable). At first glance, at the very bottom - an oscillator for quartz, then the main digital stuffing is a divider by 65536, the role of “snakes” in the upper part is not completely understood. After etching the metal:

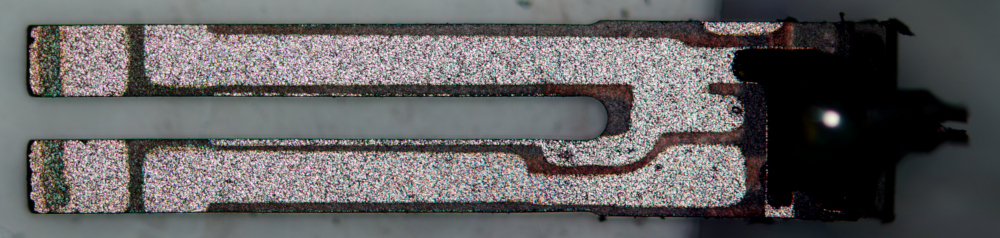

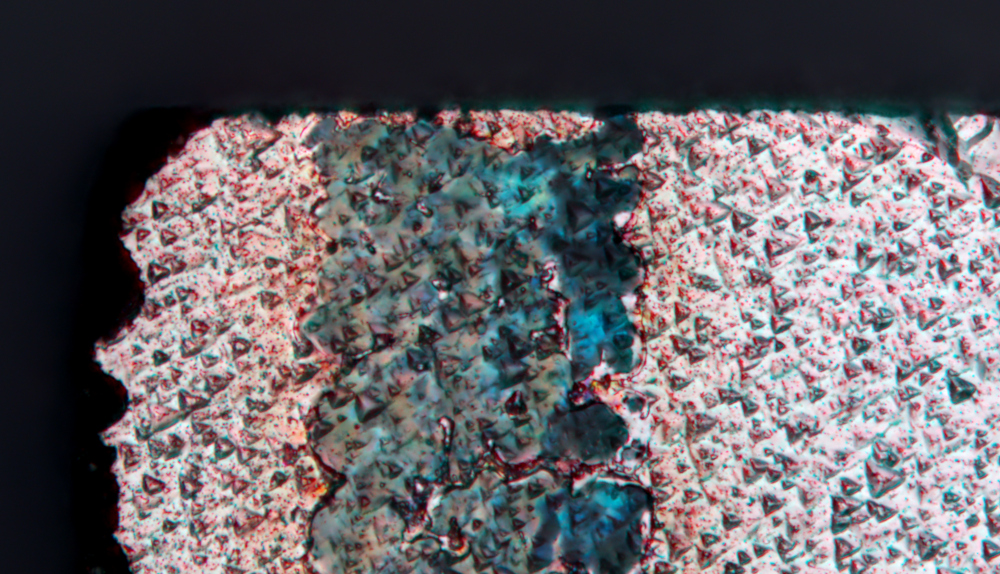

Certainly, the quartz frequency was tuned by a pulsed laser. Before the lasers, they carefully and mechanically polished the factories until they hit them (with an error tolerance of no more than 0.004%, then there was more to do ...).

Certainly, the quartz frequency was tuned by a pulsed laser. Before the lasers, they carefully and mechanically polished the factories until they hit them (with an error tolerance of no more than 0.004%, then there was more to do ...). But what is this pyramid throughout the area? Quartz is sawed in such a way that the slice is on the XY plane of crystallographic orientation, and in any operations (etching, machining) - the crystals like to break down along their crystal lattice directions, in this case leaving the pyramids in the Z direction.

Management of the quartz cut plane - and allowed him to conquer the world (along with the presence of the piezoelectric effect). By choosing the direction of the cut crystal lattice of quartz - you can control the dependence of the resonance frequency error on temperature. With a tuning fork's XY cut, a “zero” waist of the frequency error graph is obtained in the region of 25–30 ° C, which provides an almost zero error when worn on the arm.

Choosing a more complicated direction of quartz cutoff - you can find options with two zero crossings, which gives a smaller error in a wide temperature range. So there were popular sections - AT (99% of quartz are such) and SC (better suited for ultra-stable generators with a “stove”, has a flat “shelf” in the area of elevated temperatures).

Mechanical oscillators of a fully mechanical clock have a much greater temperature coefficient (and much more depends on what - the power of the plant, the direction of the gravity vector, the magnetic field).

Surprisingly, the world has completed a full turn - and returns to mechanical MEMS oscillators.with all their flaws and dependencies on the outside world. With temperature dependence struggling brutal calibration and digital compensation. To achieve high quality, these high-tech mechanical oscillators work in a vacuum, which makes them unreliable in the atmosphere of helium, which can pass through the silicon case (this problem is heard because of the sensational failure of the last iPhone in the atmosphere of 2% helium). All this started for the sake of smaller dimensions (especially thickness) and greater manufacturability.

But quartz due to its unique properties (low CTE, piezoelectric effect, control of the shape of the graph of the resonant frequency from the temperature direction of the cut crystal, jitter) will remain indispensable in many applications in the foreseeable future.

As a curiosity

Of course, I tried to overclock the clock by connecting it to a signal generator. If at the nominal frequency the clock goes with an amplitude of only 1V, then the acceleration at 394x requires 4.8V, 507.4x - 7V, and finally 582x - 10V.

600x, so that 10 minutes in 1 second flew by - it was not possible to press in any way, but 582 movements per second are already quite a few.

These high frequencies are “resonant”, there are only a few hertz where the clock will pick up such a setting frequency. And if you back down from her at 1-2 Hz - the clock will go in the opposite direction:

The most difficult thing in this article turned out to be - not to corrode the microcircuit in boiling acid, but to record a video so that the ticking of the clock can be heard. Very much the modern world teaches noise. And then I even had to take the signal generator to the next room - otherwise the hum of the transformer jammed everything.

If you liked the article - you can support the project on Patreon and - read shorter notes about chip breaks on zeptobars.com .