Nothing extra. The best of constraint theory

Hello. We make metal products. Stamping, welding, painting, packaging. A year ago, I met with the “Theory of Constraints” (hereinafter TOC). And he tried to imagine how the theory from books can be applied in practice. Trees, diagrams, clouds and other terms of this teaching did not fit into the Russian mentality of the production worker. Why Russian? Because in Russia, all methods (CBT, Lean Manufacturing, etc.) do not take root well in enterprises. And do not say that there are successful projects. Yes they are. But the lower the employee is in the ranks, the worse his attitude towards these innovations is. Lower is worse. The fact is that such an employee does not see the whole picture. Yes, and he does not need. This is not his concern. They told me to stick the cards on the box, which means we will glue them, otherwise the bonuses will still be deprived. The task of a competent leader to take something very valuable from each theory. What can be applied using simple algorithms and calculation methods.

In general, I liked the CBT. But from it I took only those positions that are easily transferred to production reality. Buffer, color scheme, MTO and MTA control (custom production and availability), etc. - this is what can ideally be operated in a production environment. And the clouds, trees and other natural phenomena poorly take root in the heads of employees. It seems to me that a cloud of definitions and metaphors impedes, blocks the work of the already clumsy mind of an average employee. This is not necessary for the smart, but it will not help the stupid. One thing to remember here. In Ayn Rand's Atlas Shrugged, there are wonderful words. In a brief retelling, they sound like this: “There are no contradictions in the world. If it seems to you that you are faced with a contradiction, check the source data, there is an error in them. ” All! That’s all you need to learn. Should work, but does not work, check the source data. Common sense helps you. And you can build clouds and trees, inject and continue to confuse employees.

So how do we translate theory into algorithms? Started with software. We have written and are still writing. Use excel to implement a beautiful theory - catch butterflies with a fishing net. Although, if you expand the staff and hire a cell filling employee, then office is your option. Everything should be automated right away so as not to redo it.

Managers accept and place an order in a production plan (MTO). The program calculates the percentage of completion depending on the filling of the warehouse and scatters the warehouse for orders depending on the date of shipment, priority and quantity. The storekeeper enters daily data into the database on incomes from production, from a computer or from a phone (android application) through a barcode. By the way, we are moving away from the stationary workplace of the storekeeper. The reason is errors when entering the warehouse. They did one thing, brought another. An error in one click affects the operation of the system. In the case of the phone and barcode, this problem was minimized. The storekeeper scans the box directly from the temporary storage area and enters the database with one click.

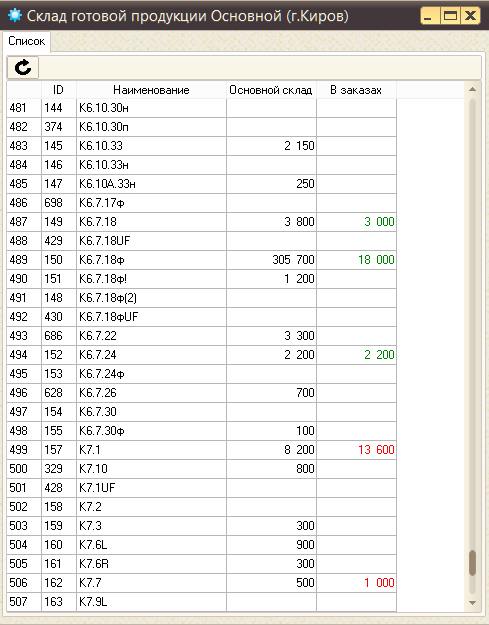

Finished goods warehouse:

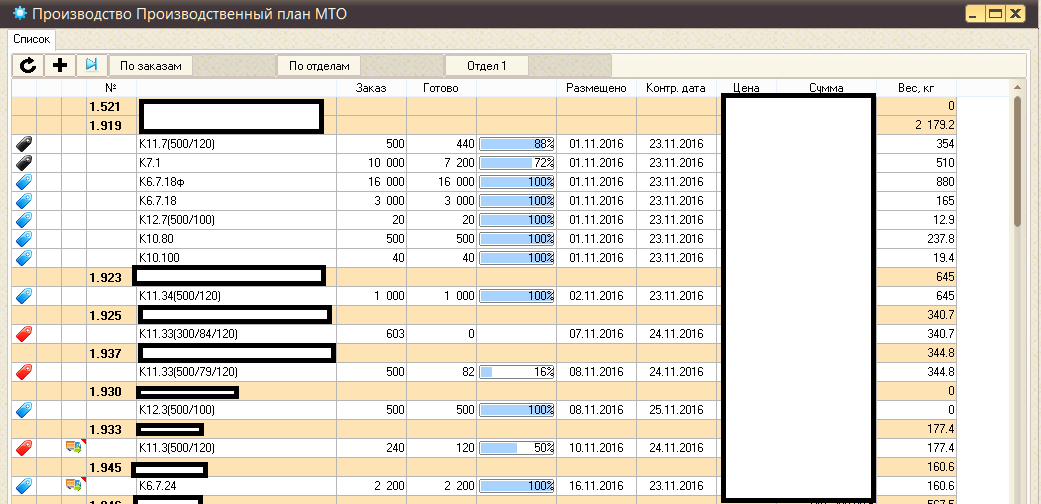

MTO Plan:

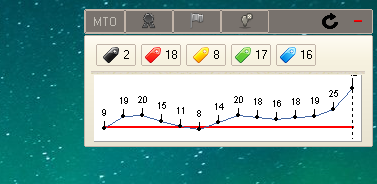

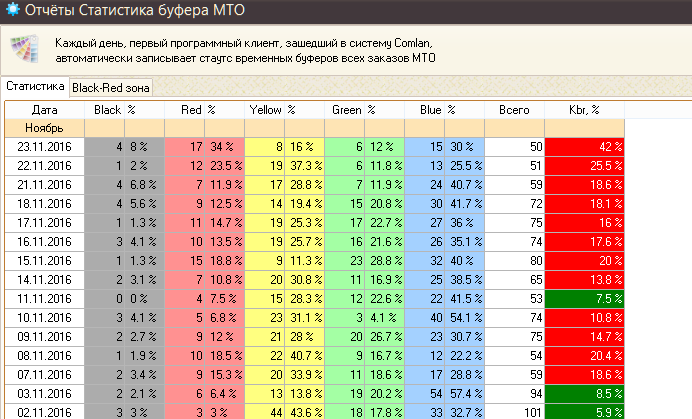

The system monitors the time buffer (the time from the moment the order arrives until the key date) of each order and writes the percentage of color buffers to the database. In the picture below it is presented as a widget for the desktop, the graph shows the percentage of red-black orders. According to theory, they should not be more than 10%. As you can see, we have something to work on.

Desktop MTO widget:

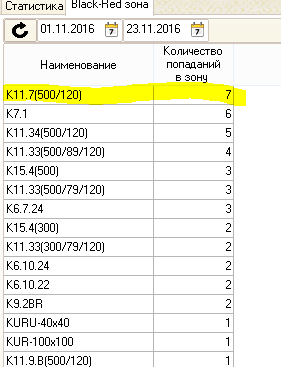

You can see which products are most often in the red-black zone. And pay special attention to them (to keep a larger quantity in stock during the season). For example, the product K11.7 (500/120) in 22 days got into this zone 7 times. Therefore, we go to production and think how to fix it.

Statistics of getting into the red-black zone:

Everyday Buffer Database:

Next time I’ll talk about the implementation of the MTA mechanism (production to ensure availability).

In general, I liked the CBT. But from it I took only those positions that are easily transferred to production reality. Buffer, color scheme, MTO and MTA control (custom production and availability), etc. - this is what can ideally be operated in a production environment. And the clouds, trees and other natural phenomena poorly take root in the heads of employees. It seems to me that a cloud of definitions and metaphors impedes, blocks the work of the already clumsy mind of an average employee. This is not necessary for the smart, but it will not help the stupid. One thing to remember here. In Ayn Rand's Atlas Shrugged, there are wonderful words. In a brief retelling, they sound like this: “There are no contradictions in the world. If it seems to you that you are faced with a contradiction, check the source data, there is an error in them. ” All! That’s all you need to learn. Should work, but does not work, check the source data. Common sense helps you. And you can build clouds and trees, inject and continue to confuse employees.

So how do we translate theory into algorithms? Started with software. We have written and are still writing. Use excel to implement a beautiful theory - catch butterflies with a fishing net. Although, if you expand the staff and hire a cell filling employee, then office is your option. Everything should be automated right away so as not to redo it.

MTO (custom production)

Managers accept and place an order in a production plan (MTO). The program calculates the percentage of completion depending on the filling of the warehouse and scatters the warehouse for orders depending on the date of shipment, priority and quantity. The storekeeper enters daily data into the database on incomes from production, from a computer or from a phone (android application) through a barcode. By the way, we are moving away from the stationary workplace of the storekeeper. The reason is errors when entering the warehouse. They did one thing, brought another. An error in one click affects the operation of the system. In the case of the phone and barcode, this problem was minimized. The storekeeper scans the box directly from the temporary storage area and enters the database with one click.

Finished goods warehouse:

MTO Plan:

The system monitors the time buffer (the time from the moment the order arrives until the key date) of each order and writes the percentage of color buffers to the database. In the picture below it is presented as a widget for the desktop, the graph shows the percentage of red-black orders. According to theory, they should not be more than 10%. As you can see, we have something to work on.

Desktop MTO widget:

You can see which products are most often in the red-black zone. And pay special attention to them (to keep a larger quantity in stock during the season). For example, the product K11.7 (500/120) in 22 days got into this zone 7 times. Therefore, we go to production and think how to fix it.

Statistics of getting into the red-black zone:

Everyday Buffer Database:

Next time I’ll talk about the implementation of the MTA mechanism (production to ensure availability).