Overview: 3D printing technology for metal casting

In this article we will talk about traditional casting technologies and how they change with the use of 3D printers . And most importantly, what existing 3D printers on the market are suitable for implementation in such production today.

Table of contents

About casting

Comparison with traditional technology

Casting process algorithm using additive technologies

Applications

3D printers and 3D printing technologies for casting

FDM models (FFF): layer-by-layer

fusion PICASO 3D Designer X

SLS - Selective Laser Sintering - selective laser sintering

Sentrol SS600G

SLA - Stereolithography Laser Apparatus - Laser

Stereolithography Zrapid iSLA1100

DLP - Digital Light Processing

FlashForge Hunter DLP

Voxeljet

Voxeljet VX 1000

3D printers for making molds

Binder Jet technology - applying the binder

Sentrol SB1000

SLS printing of molds

Solar 3D printing

Total

About casting

The end product of the foundry is castings - future parts or billets. Their weight can be as much as a few grams, as well as a few hundred tons.

This is how it is done at the machine tool plant.

The following features of the use of casting in production can be distinguished:

- the ability to obtain products with a mass of several grams to hundreds of tons, with a complex geometry and a variety of mechanical and operational properties;

- the possibility of obtaining products whose materials or dimensions make it impossible or unprofitable to create them by other methods;

- Castings are as close as possible, in size and shape, to finished products, as opposed to blanks obtained by volumetric hot stamping or forging.

Comparison with traditional technology

In the traditional casting process, the master model can be made by hand or by machining. It is impossible to implement some forms manually. For the manufacture of master models, five-axis CNC machining centers are used, which significantly increases the possible variety of forms, but the cost of such a waxing or master model increases markedly. This way of producing castings is relevant for mass production; in the small and medium series, it is, most often, not economically feasible - here the use of 3D printing is more rational.

The graph of model cost versus the number of copies produced shows the effectiveness of the application of additive technologies.

Algorithm of the casting process using additive technologies

One of the challenges facing the technologists of any foundry industry: minimizing labor-intensive operations for the machining of workpieces. It is solved by the fact that the castings should be as close as possible to the parameters of the necessary parts, which also saves money and time. Here innovations come to the rescue, in the face of additive technologies that allow speeding up the process technology, bypassing the traditional first steps in casting technology. The manufacturer can in one operation get the necessary foundry model or shape.

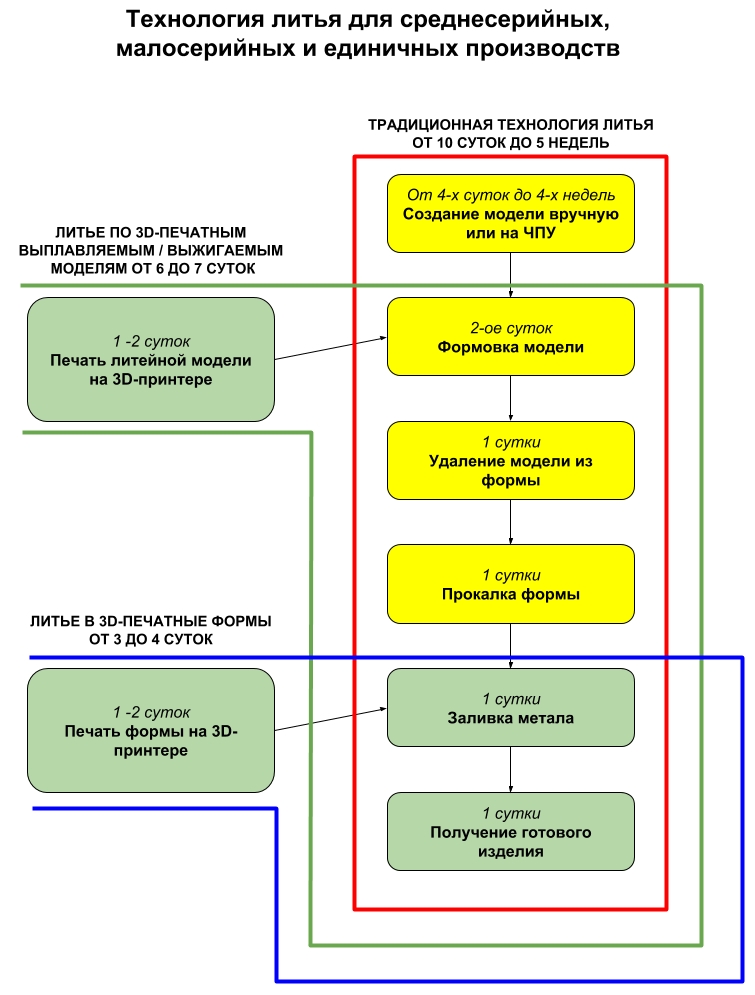

In the red area - the traditional casting process, in the green and blue - casting using additive technologies - production times are reduced by 2-6 times.

Direct printing of a product that has already been introduced in many modern industries is, from an economic point of view, more expensive than traditional casting. Therefore, 3D printing of models for smelting and burning, as well as the synthesis of molds and cores already ready for casting, is of particular interest.

Casting using additive technology is more cost effective than direct printing.

Areas of use

Master models and molds printed on a 3D printer are used in jewelry enterprises, in the manufacture of dental and orthopedic products, in design offices, for research and development, in training centers and prototyping centers.

Geometrically complex castings resulting from the use of additive technologies are used in film and on television, when you need to quickly make unusual props of complex shape.

Model Aston Martin 1960 DB 5 agent 007, for the film “Coordinates: Skyfall”, was created using additive technologies, for the sake of preserving the original car in stunt scenes.

Scenery cast using sand molds printed on a 3D printer.

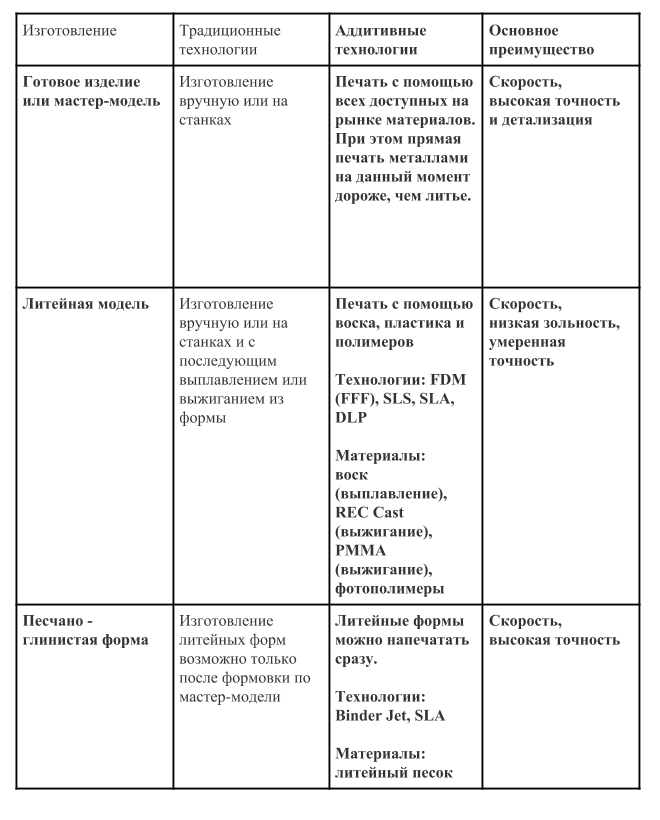

3D printers and 3D printing technologies for casting models

To obtain injection molding models using 3D-printing technology FDM (FFF), SLS, SLA, DLP. These technologies allow you to print the necessary model for the subsequent smelting or burning out of the injection mold formed around it. For melted models, wax is used, for burned out - PMMA, CAST-plastic and special photopolymers.

The main advantage of using such a solution is the absence of the need to prepare special equipment, for example, a mold, and a low ash content of materials upon burnout. The prepared 3D model is immediately sent to print and, after a small post-processing, is ready for use.

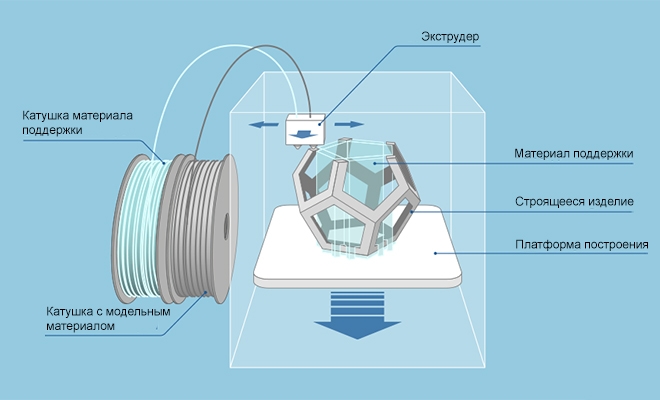

FDM (FFF): fusion layer by layer

The 3D printing method, widely known to professionals and fans of additive technologies, does not require additional description.

The material used for FDM printing of burning models is a special plastic, or a composite with high wax content.

The principal device FDM (FFF) is a printer.

The process of 3D printing using FDM technology.

PICASO 3D Designer X

PICASO 3D Designer X - FDM printer with a construction area of 200x200x210 mm, which can print with materials such as ABS, PLA, HIPS, PVA, ULTRAN 630, ULTRAN 6130, ASA, ABS / PC, PET, PC, FRICTION, CAST, RELAX , ETERNAL, FLEX, RUBBER, SEALANT, PETG, AEROTEX, CERAMO, WAX, SBS, SBS PRO, PROTOTYPERSOFT, PRO-FLEX, TOTAL PRO, NYLON and PEEK with a speed of up to 100 cm ³ / h and with a layer thickness of 10 microns.

SLS - Selective Laser Sintering - selective laser sintering

It is used for the manufacture of master models of complex shapes, moderate accuracy and relatively large dimensions.

How it works: in a working chamber filled with an inert gas, for example nitrogen, a roller rolls polystyrene powder with a particle size of 50-150 microns onto the platform. A new layer is sintered with a CO2 laser (with a temperature of 100-120 ° C) over the cross section of the “body” of the CAD model. Then the working platform is lowered by 0.1-0.3 mm, after which the next layer is printed.

The principal device SLS-printer.

The printed model does not require support, because the material itself is the reference material - the surrounding powder. Unused material is reused.

The model produced on such a printer is poured with a mold material, from which it is then burned in a calcining furnace. Burnout produces flammable gases that need to be neutralized. There is a danger of the mold clogging up with the burned-out ash of the model, because materials for its manufacture are taken with low ash content, in hundredths of a percent.

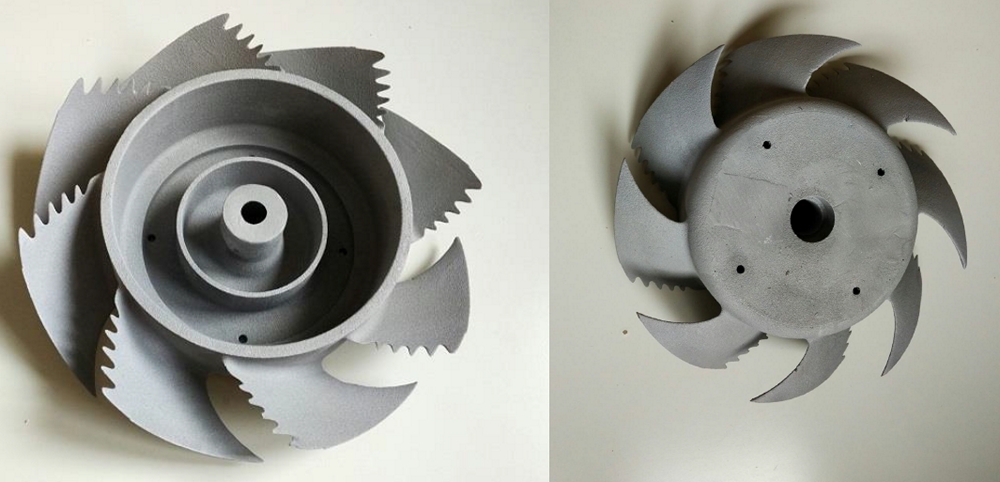

On the left - polystyrene 3D-printed model, on the right - aluminum casting

Sentrol SS600G

Sentrol SS600G - SLS 3D printer with a construction area of 600x400x400 mm, printing at a speed of 26 cm³ / h, accuracy of 300 microns in XY and 250 in Z.

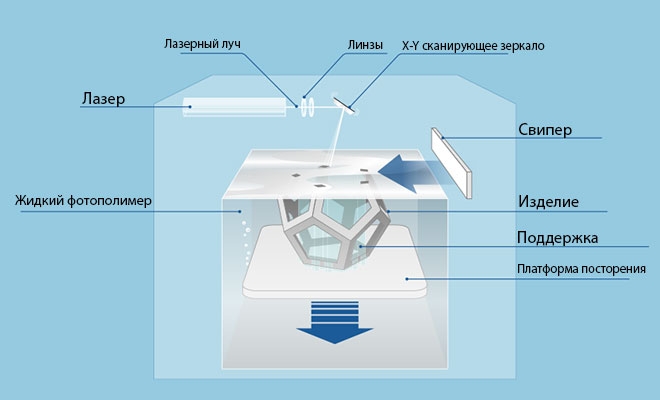

SLA - Stereolithography Laser Apparatus - laser stereolithography

The printing process is similar to SLS, but instead of the powder material - liquid. The UV laser affects the material, which is selectively and layer-by-layer cured.

The material used photosensitive resin and photopolymers. The working platform is lowered or raised (depending on the location of the light source) and the liquid is polymerized by a laser at specified points. Unused liquid material, as in the case of powders, can be reused for printing subsequent models.

3D printing process using SLA technology.

The resulting models have high surface quality, which eliminates the need for further machining.

Plastic stereolithographic models of impellers for water propellers (top left), wax models made from them (bottom left) and finished metal casting (right).

On the left is the SLA model, on the right is a silver casting.

Zrapid iSLA1100

The Zrapid iSLA1100 3D laser printer prints objects up to 600x1000x1000 mm at a speed of 100 ~ 230 grams / hour.

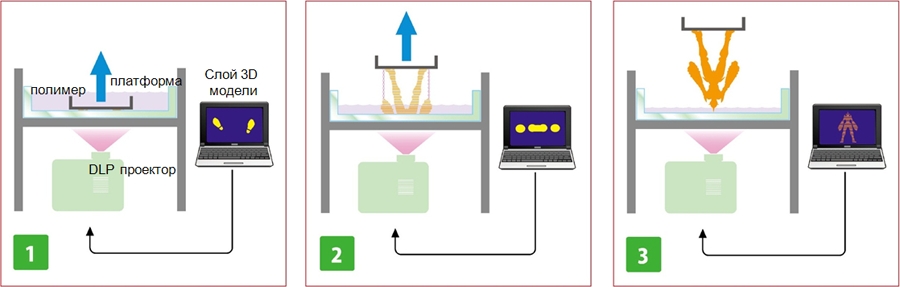

DLP - Digital Light Processing

For curing the photopolymer used DLP-projector on DMD chips. This is the main difference from the SLA technology, which uses a UV laser. Another difference is that the layer is projected entirely, all the pixels are at the same time, and not drawn by a laser beam, which speeds up the process.

DMD chip with two micromirrors.

Models printed on such a printer require support removal and ultraviolet processing. That is, the post-processing for the models obtained using this technology does not differ from those printed using the SLA technology.

DLP printing process.

The light “spot” of a DLP projector, depending on the printing of a particular layer.

DLP printing allows you to get a model faster, but with a less smooth surface than on an SLA printer.

SLA (left) and DLP (right).

Difference of detailing at the press on SLA technology and DLP technology.

FlashForge Hunter DLP

FlashForge Hunter DLP is a DLP printer with a layer thickness of 25-50 microns and a print area of 120x67.5x150 mm.

The printed model and the finished product are made using a FlashForge Hunter DLP printer.

Voxeljet

Voxeljet is a method of layer-by-layer bonding of plastic powder or sand, developed by the eponymous German company. Its counterpart is Binder Jet, it works only with sand.

Such 3D printers appeared as a result of a combination of MJ and SLS technologies. Using PMMA as a material, it is possible to obtain burnable models. PMMA - polymethyl methacrylate, if simpler - crushed plexiglass with a fraction of 85 μm. The printing head lays on a working platform a layer of powder with a thickness of 100 to 150 microns. Next, a binder is applied, on top of which the powder layer is placed again. So the process is repeated until the complete production of the required model. In the case of sand, we get an injection mold.

As in the case of the SLA-technology, the Voxeljet model is suitable for precision casting.

Casting on PMMA-models, without post-processing.

Voxeljet VX 1000

Voxeljet VX 1000 provides a print area of 1060 x 600 x 500 mm, a layer thickness of 100 microns, an accuracy of 0.3% and a speed of up to 36 mm / h vertical.

3D printers for making molds

Binder Jet and SLS technology can quickly get a quality casting mold. 3D printers working with these technologies print molds from special foundry sand.

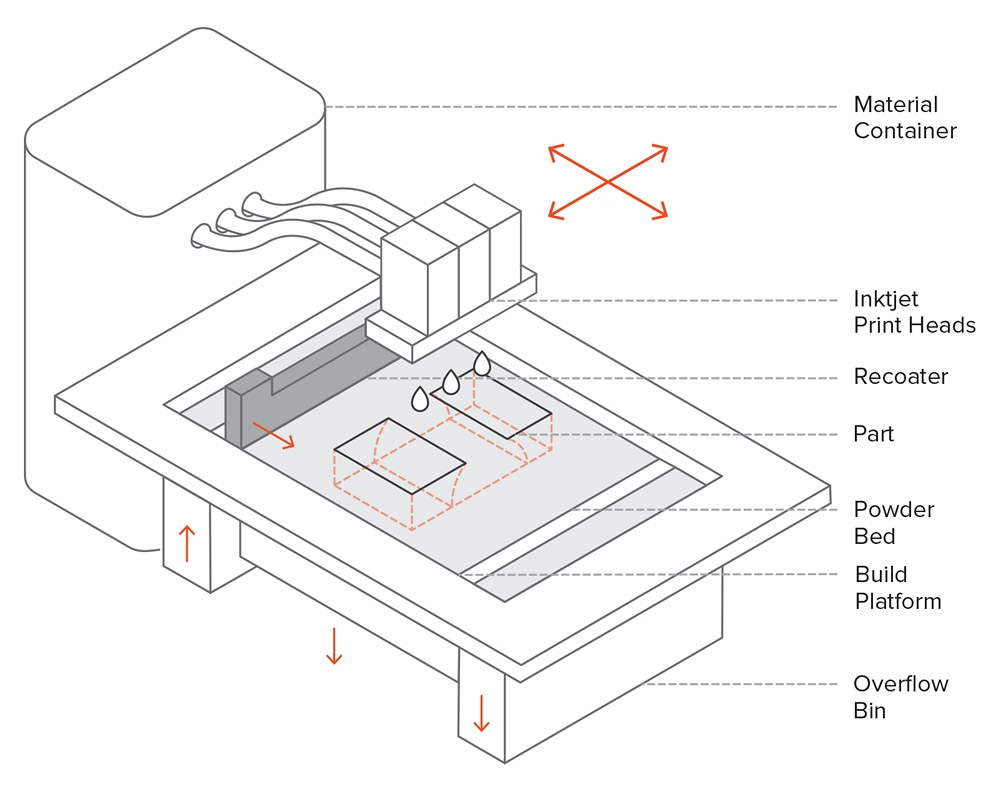

Binder Jet technology - applying binder

This technology makes it possible to print a sand form that is complex in geometry without any additional processing. After printing, you can immediately start casting. The main advantage of Binder Jet technology is that there is no need for any special conditions for the operation of such a printer: printing is possible at room temperature.

The process of printing technology Binder Jet.

The material, in this case sand, is distributed on the working platform with a roller. Next, the printhead applies the bonding adhesive over the powder. The platform is lowered through the thickness of the model layer and the object is formed where the sand is bound to a liquid (i.e., glue). Unused material, by analogy with SLS technology, is support for a future model.

The principal device printer with Binder Jet technology.

Binder Jet technology castings.

Sentrol SB1000

The Sentrol SB1000 3D printer prints using Binder Jet technology with a layer thickness of 100 microns, an XY accuracy of 0.0625 mm and a model size of up to 120x67.5x150 mm.

SLS printing of casting molds

The main difference from the previously mentioned SLS technology is the use of foundry sand previously clad with polymer as a print material. The material is sintered with a laser, after which it is cleaned. The resulting form is placed in a tempering furnace for curing, which occurs at a temperature of 300-350 ° C. The main difference from Binder Jet is a higher detail of the finished mold. However, it takes more time to get the finished form, because of the need for additional processing.

Solar 3D printing

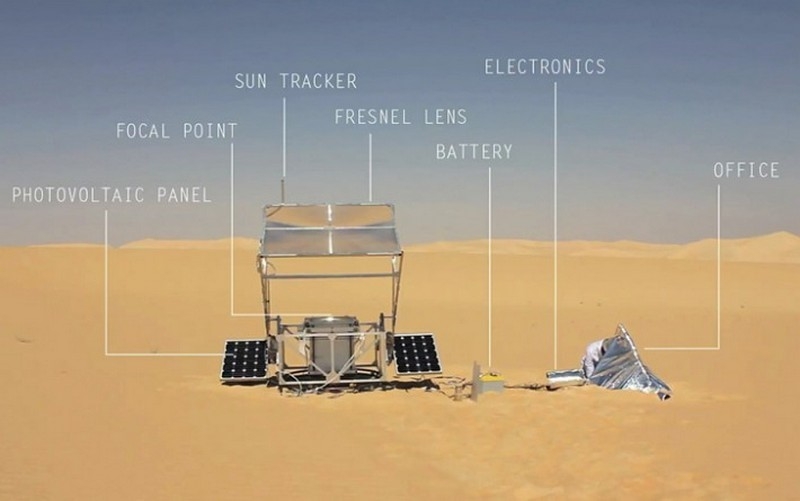

By the way, there is another interesting technology for printing with sand - Solar Sinter. It was developed by German engineer, designer and artist Markus Kaiser . Solar 3D printing is perfect for creating sand casting molds, albeit with very low accuracy.

If you are going to print in the desert, you must take the office with you. Marcus Kaiser offers a pyramidal tent with a reflective coating - an excellent shelter from the hot sun.

If your business is in the desert, then this is the best option - sand and sunshine are all around, which are available on a standard nine-hour shift. You only need to bring the printer with the computer. The printer is equipped with a Fresnel lens, which concentrates sunlight into a beam, which makes it possible to melt sand with a temperature of 1400-1600 ° C; solar tracker that tracks the position of the sun and turns the lens to it; and photocells to power the installation drives. The main plus is the savings on electricity, materials and rental space. But more importantly, perhaps, is conceptuality.

The process of printing on a solar 3D - printer.

Such a printer, and due to the specifics of the application, and because of the low accuracy of the models obtained, can hardly be used for industrial needs. But for artists and artisans, it will become a real find. It is probably a dubious task to print molding forms on it, but art objects are the most it.

Removing the model from the working area of a solar 3D printer is done with a tablespoon. You can use the plug, but the speed will be lower.

But seriously - who knows where the technology will go next? Sometimes crazy projects open up new opportunities.

Total

The introduction of 3D printing makes the casting process cheaper and faster, allows you to make models and molds for casting with a complex geometry and various dimensions, without losing the accuracy of the resulting casting.

To obtain melted and burnable models, it is recommended to use printers operating with FDM (FFF), SLS, SLA / DLP, Voxeljet technologies. The materials used have a low percentage of ash, and print models faster than manually or using a CNC machine .

An example of the technological chain for casting with the use of a melted model.

For the production of casting molds, Binder Jet and SLS printing technologies with suitable material for the forms are suitable.

Additive technologies in casting are applicable in cases where it is necessary to obtain a master model or mold for future casting as cheaply and quickly as possible, for example, in design bureaus and at pilot plants. They are also applicable in mass production - if micron accuracy is not required, the difference in speed and cost of work makes them much more attractive than machining on a CNC router.

Now you can order a metal or plastic casting and look at the result of using 3D printing in casting.

You can choose a 3D printer for integration into the foundry or equipment for the foundry in the Top 3D Shop .

Want more interesting news from the world of 3D technology?

Subscribe to us in the social. networks: