Instead of building - 3D printing

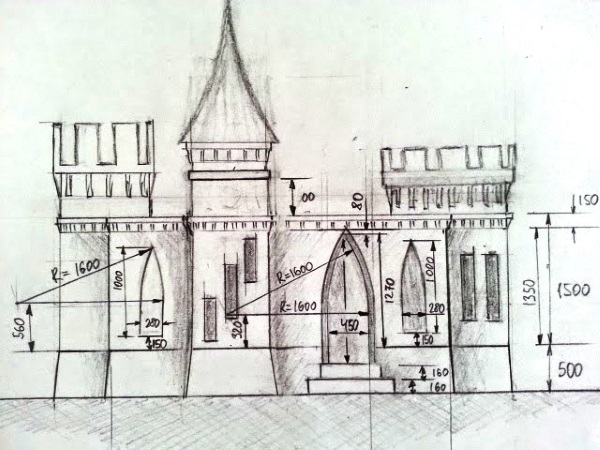

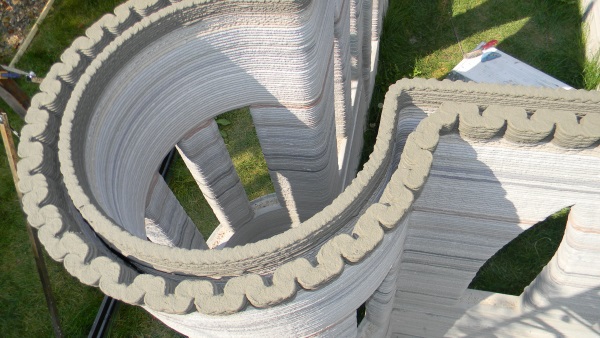

Meanwhile, in Minnesota, the “Native American” Andrei Rudenko pushes the boundaries of 3D printing, namely: in his backyard using a three-dimensional printing method from concrete, he erects a model of a medieval castle on an area of 3x5 meters. In the process, the prototype concrete printer is improved and updated.

Creating one of the largest objects in the field of 3D printing, the inventor wants to come to a reliable way to build real-life residential buildings that can withstand various weather conditions. Andrey has an engineering and architectural background, which allows him to experiment and find interesting solutions at the intersection of architecture and 3d printing. The lock at the same time represents an interesting difficult task and an excellent demonstration of the capabilities of the printer.

Andrei: “I was interested in similar technologies from my teenage years. My experiments began 20 years ago, but at that time there were no suitable computers and programs. Only a couple of years ago I stumbled upon the RepRap project and took up my car again. It took a year to build and develop concrete mixes. An additional incentive was the natural phenomenon of layered sandstone, which I saw in Arizona during my trip several years ago. Ideally, I want to achieve a similar appearance. ”

Since Andrei financed the project from his own funds, these restrictions also led to original engineering solutions.

Andrei: “At the beginning of my work, the sponsors were skeptical, because they did not believe that the project would go so far. Now that the structure is ready and the capabilities of the printer are obvious, I plan to arrange an auction to sell the first house. Since this will be the first printed house, I hope this event will attract a lot of attention. "

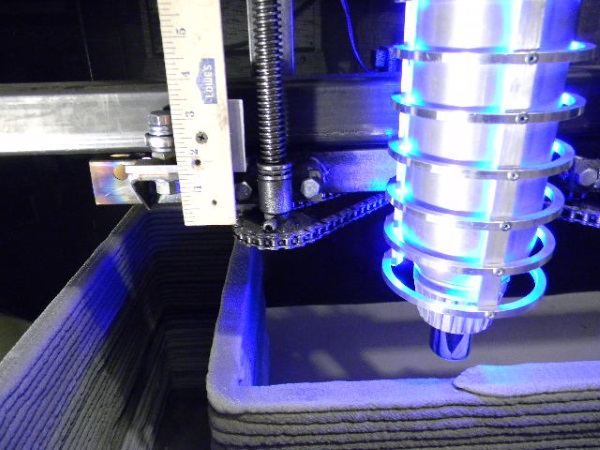

To print a house, a large printer was required, so I had to design it from scratch. Despite the great support of the RepRap community, the final machine was made according to the original project. It is controlled using the Arduino Mega 2560 and special stepper motors.

Andrei: “For a large printer I had to look for special engines designed for heavy loads. The Mass Mind engines were the best.

In addition, they were the only ones who worked correctly with Marlin firmware, and were powerful enough to move the printer.

I achieve the natural effect of loose concrete without the need for post-processing. ”

Andrei also expects to develop a portable car for laying smaller, so that small construction companies could afford it. “The final price will be later, but for now I am counting on $ 30000-50000, although it all depends on the parts and model type.

Rudenko expects to supply companies with separate interchangeable printer parts so that companies can assemble their own machine according to their needs. “I can’t send the whole machine, but I can send the extruder, the control unit, various important parts so that people can build their own version of the machine.”

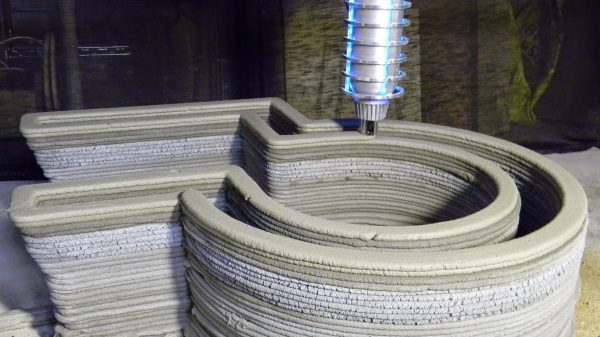

Now the printer puts about a 50-cm layer of concrete per day, although it all depends on the overall size of the structure. Usually a layer is obtained with a width of 30 mm and a height of 10 mm, although in principle any layer can be made. “For special parts such as crowns, I reduce the height of the layer to 5 mm, and in some places reduce the print speed.”

Of course, such structures require special materials.

“Cement masonry is a difficult task - it takes a long time to set up the printer and use very precise proportions of the mixture. "When testing, I encountered many problems, (for example, clogging the extruder), but I also found that the capabilities of the printer exceed original expectations."

I also had to add reinforcement to the lower and upper parts of the walls. Cement was used the most common. Although you can use quick-drying, but it will come out more expensive and a little less quality.

Rudenko is confident that this technology will achieve new heights in architecture and will be both more energy efficient than existing ones.

“I plan to focus on the development of this technology in construction and build an entire international network of enthusiasts, with the ability to provide them with do-it-yourself kits and ready-made printers in the future.”

So far, of course, affordable printers for construction remain in the uncertain future, but the inventor is optimistic. “Although styling is now in 30x10 mm layers, a great many possibilities are available by a simple click of a button.”

Based on the experience gained, the designer rebuilds the printer so that it can print without interruption 24 hours a day until the construction is completed.

It is also planned to refine the design to the possibility of printing everything at once. The castle towers were printed separately and it was very difficult to install them in place. "I also figured out how to print the roof - but so far this material is only suitable for places with a warm climate."

The next project is a full-sized real residential building. “I get a lot of messages, this proves a high interest in this new technology. “I want to be sure that on the next project my team will be able to use all the advantages of 3D printing.

I accept offers from individuals and companies who would be interested in purchasing the first printed house and who are ready to ensure payment of all project costs.” The designer also accepts offers of cooperation from architects, designers and programmers who are interested in 3D printing.

“I was sure before that I could print at home - and now I have proof. Now I am working on a prototype, which will be a small part of the rich assortment of printers that I develop. We are opening a new era in construction. So much more needs to be done. ”