Do not eat it! Useful 3D sugar printing

3D sugar printing is usually associated exclusively with cooking and pastry making. And if so, then with something frivolous and useless from a practical point of view (although desserts are great, of course).

The recent discovery of scientists from Illinois will change this attitude. They have developed a method of free printing by isomalt and have already applied it in working with microfluidic devices and biological tissues. In general, the head of the research group is the director of the Illinois Cancer Center, and the development will help in the study of cancerous tumors.

A few words about sugar printing for confectioners

Первыми догадались заправить в 3D-принтер сахар калифорнийские дизайнеры Кайл и Лиз фон Хассельн еще в 2013 году. Согласно устоявшейся легенде, они хотели сделать торт на день рождения подруги, но у них не было духовки. Поэтому торт они решили напечатать. После множества попыток они все-таки сделали верхушку для небольшого кекса с напечатанным именем подруги (пока разбирались, ее день рождения уже прошел). Решив, что это перспективное направление, супруги основали компанию The Sugar Lab и начали делать съедобные арт-объекты. В том же 2013 году стартап приобрела компания 3D Systems.

В 2014-м 3D Systems начала массовое производство принтеров для печати сахаром. В них используется послойный метод создания объектов. Сначала — слой материала, затем — слой воды, которая используется как закрепитель. Готовые объекты получаются прочными и хорошо держат форму.

Работы The Sugar Lab. Источник фото

Помимо промышленных гигантов, идею начали развивать отдельные энтузиасты — такие, как голландец Джулиан Синг. К разработанному собственноручно принтеру он сделал специальный сахарный порошок, в который добавил связующий агент.

В 2014-м 3D Systems начала массовое производство принтеров для печати сахаром. В них используется послойный метод создания объектов. Сначала — слой материала, затем — слой воды, которая используется как закрепитель. Готовые объекты получаются прочными и хорошо держат форму.

Работы The Sugar Lab. Источник фото

Помимо промышленных гигантов, идею начали развивать отдельные энтузиасты — такие, как голландец Джулиан Синг. К разработанному собственноручно принтеру он сделал специальный сахарный порошок, в который добавил связующий агент.

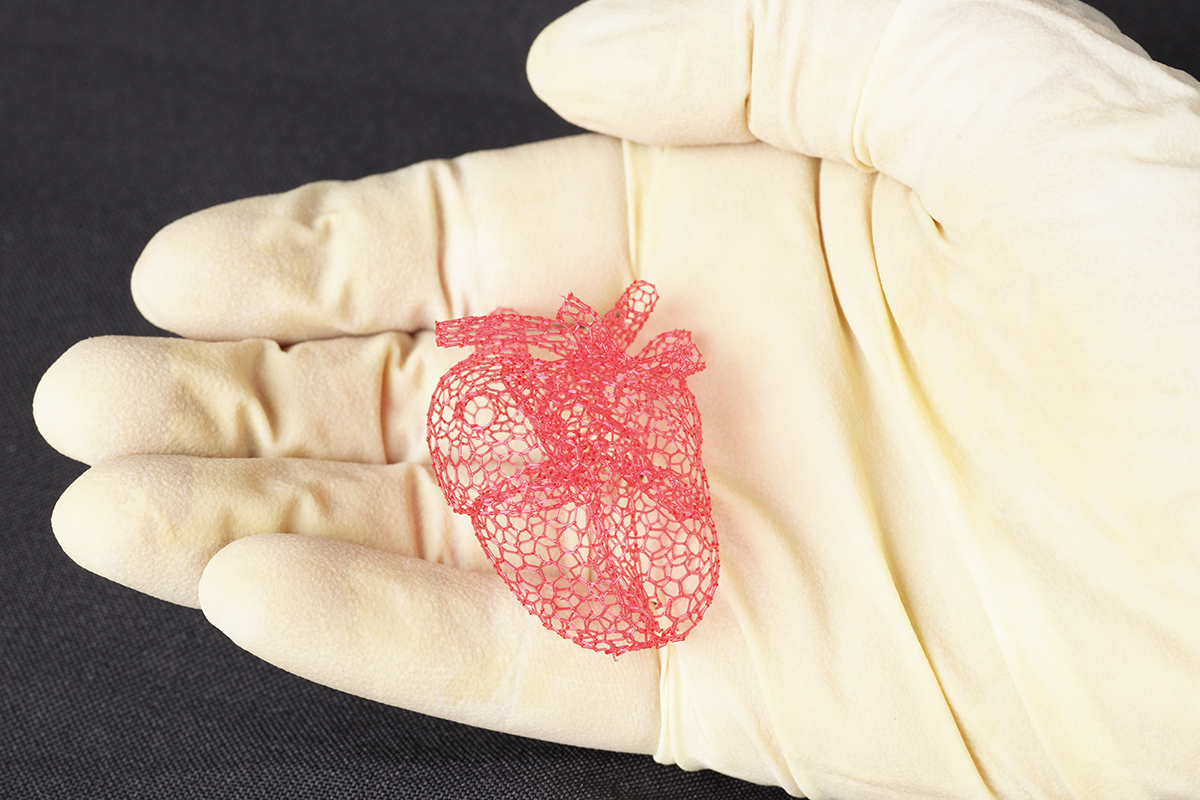

Engineers at the University of Illinois have created a 3D printer that prints with sugar and allows you to create detailed structures, such as commercial 3D printers cannot print. Instead of creating a layer-by-layer object, this printer makes a network of thin filaments of hardened isomalt, a type of sugar alcohol that is used in cough drops.

The project was led by the director of the Illinois Cancer Center Rohit Bhargava . He is a professor of engineering sciences and has long been working with chemists, electrical engineers and machine builders. Due to his specialization, Bhargava conducts research in the field of oncology. The new method will improve the methodology of these studies.

Scientists have paid attention not to the usual sucrose, but to one of its variants. This isomalt, a food additive E953 - it is used in the manufacture of products for diabetics. Isomalt is harmless to the body, while the sweet taste and melts well. Therefore, it is also massively used in the preparation of sweets, ice cream, chocolate and other sweets.

Isomalt decor example Isomalt

crystals are easy to heat and melt. But the main thing is that the material quickly hardens and retains the shape that was given to it. It is almost not deformed when cooled, and the plasticity of sugar helps to maximize the detail of objects.

According to Bhargava, isomalt printing is a great way to create a skeleton for attaching soft tissues to it, growing cells or tissues. Subsequently, this frame alone will dissolve. One possible use is tissue cultivation or tumor testing in the laboratory. Cell cultures are usually grown on a flat base (in petri dishes). This allows you to understand some of the characteristics of the cells, but this is not the most effective way to look at the functioning of the system in the body: "In the body, everything has well-defined forms, and the form and function are very closely linked."

In a published report, researchers describe the materials and mechanisms of free printing with isomalt. “Free” here means that as the nozzle moves in space, the molten material will solidify into a solid structure.

Printing by other types of sugar has already been studied before, but there have been problems with burning and crystallization of the material. The team found that isomalt is suitable for 3D printing and is less susceptible to burning and crystallization. Then the researchers had to build a printer with the right combination of mechanical parts: with the right melting point, pressure in the extruder, the right nozzle diameter and speed.

One of the advantages of the resulting isomalt structures is the ability to create thin tubes with circular cross sections, which is impossible using conventional polymer printing. When sugar dissolves, it leaves a series of connected cylindrical tubes and tunnels that can be used as blood vessels to transport nutrients to tissues or to create channels in microfluidic devices.

Another advantage is the possibility of precise control of the mechanical characteristics of each part of the structure due to the introduction of minor changes in printing parameters.

“For example, we print a rabbit. By setting different printing parameters, we can make the mechanical properties of the rabbit's tail, back and ears be different, says Bhargava. - It is very important for biological research. With layered printing, the same material stands out in the same volume, so it is very difficult to adjust different mechanical properties. ”

The Bhargava group is already using isomalt scaffolds in microfluidic devices and working with cell cultures. Now scientists are developing a coating for these frameworks to control their dissolution rate.

More about new devices and 3D printing techniques - at 3D Print Expo . Until tomorrow, inclusive, we reduced the cost of tickets.