The imperceptible complexity of rocket technology. Part 2: Solid Fuel Engines

In the comments to the first article, they rightly pointed out to me that I did not talk at all about solid propellant engines that are used in astronautics. Indeed, even a simple educational program did not fit into one article. Therefore, I invite those who wish to read the sequel.

Traditions of antiquity deep

Black (smoky) gunpowder was invented by the Chinese in the ninth century. And already in the eleventh century there are documentary evidence of the creation of military rockets on black powder (Wujing Zunyao 1044):

Pay attention to the design of the rocket in the center. This arrangement of military missiles remained unchanged for more than eight hundred years, until the beginning of the twentieth century, and fireworks are still being produced with it!

Human thought did not stand still. Already in 1409, Korea came up with the multiple launch rocket system ( Hvachha ):

There is also a legend about a Chinese official, Wang Hu , who in approximately the sixteenth century assembled an apparatus from a chair, two kites (not in all versions of the legend) and forty-seven missiles (obviously from shells like Hvachha):

Alas, the inventors of that time were fearless from ignorance, they did not think about the methodology of flight design tests, and suffered from excessive optimism. Therefore, the first test was the last. When the engines roared and the smoke cleared, neither Wang Hu nor his apparatus was found.

Missiles along with conquerors from the East (Mongols, Ottomans) came to Europe. The very word "rocket" is from Italian "small spindle." With different intensities, missiles were used throughout Europe and Asia.

The next notable stage was the fourth Anglo-Mysore war(1798-1799). Mysore missiles for the first time in the world had a steel shell, various purposes (incendiary, anti-personnel with cutting edges) and were massively used. The missile corps of Tipu Sultan totaled five thousand people.

Impressed by the British, who also captured hundreds of missiles as trophies in Seringapatama, decided to reproduce the technology. So Congreve missiles were born, which were widely used in the Napoleonic wars and subsequent conflicts, and even leaked to the US anthem.

Starting from the mid-nineteenth century, rifled artillery began to beat rockets both in range and accuracy, and the salvo type of the Hwacha type was forgotten. Therefore, military missiles gradually left the stage, however, even in World War I they were still used. Pictured is the French Newpor-16 with Le Prieur missiles to combat airships and balloons. Despite the electric fuse and installation on an airplane, these are the good old powder rockets of the same layout as the eleventh century Chinese.

I went ashore "Katyusha"

Rockets on black powder did not become more complicated and powerful due to the limitations of the powder itself. It was impossible to make a powder checker with stable parameters in a batch of large caliber, and burning for at least a couple of seconds. The development of solid rockets required new material. At the end of the nineteenth century smokeless powder was invented. However, the rocket could not be made on artillery smokeless powder. The search for smokeless rocket propellants began.

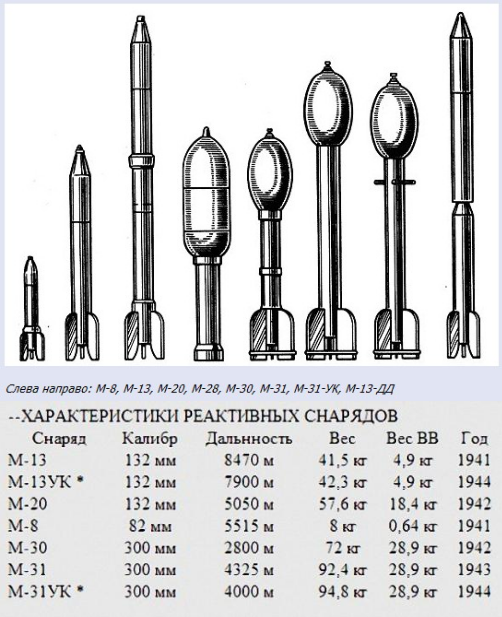

The Gasdynamic Laboratory achieved the greatest success in this matter.Tikhomirova and Artemyev in the USSR. They created the so-called ballistic gunpowder, from which it was already possible to make sufficiently large pieces and put them in rockets. In addition, in time they remembered the idea of volley fire. That is how Katyusha was born - RS-82 and RS-132 shells for aviation, M-8 and M-13 for ground installations. More information about gunpowder, their types and production can be found here .

Advances in technology led to the fact that during the Second World War, the USSR more actively than other countries used solid-fuel military missiles. The weapon turned out to be very effective, was used from air, land, ship carriers, new modifications of a greater range or caliber were developed.

Resistant Blend Sergeant

Ballistic powder had its physical limitations. The maximum diameter of the checker was measured in centimeters, and the burning time in seconds. Even if von Braun wanted, he could not have made Fau-2 on ballistic gunpowder. A new type of solid fuel was needed. They became the so-called mixed fuel ("rubber fuel"). In 1942, John Parsons created the first copies of mixed-fuel engines using asphalt . And experiments with the components found that the most effective fuel is a mixture of ammonium perchlorate (oxidizing agent), aluminum and polyurethane (fuel) and polybutadiene to improve combustion parameters, molding and storage of the motor block. The first missile with a mixed-fuel engine was the Sergeant MGM-29(first flight - 1956 g), the engine of which had a diameter of 0.7 meters and worked for 34 seconds. It was a qualitative breakthrough - a missile weighing 4.5 tons and a length of 10 meters could throw a warhead weighing 0.8 tons per 135 km, and did not require a convoy of vehicles with fuel components and tens of minutes to refuel.

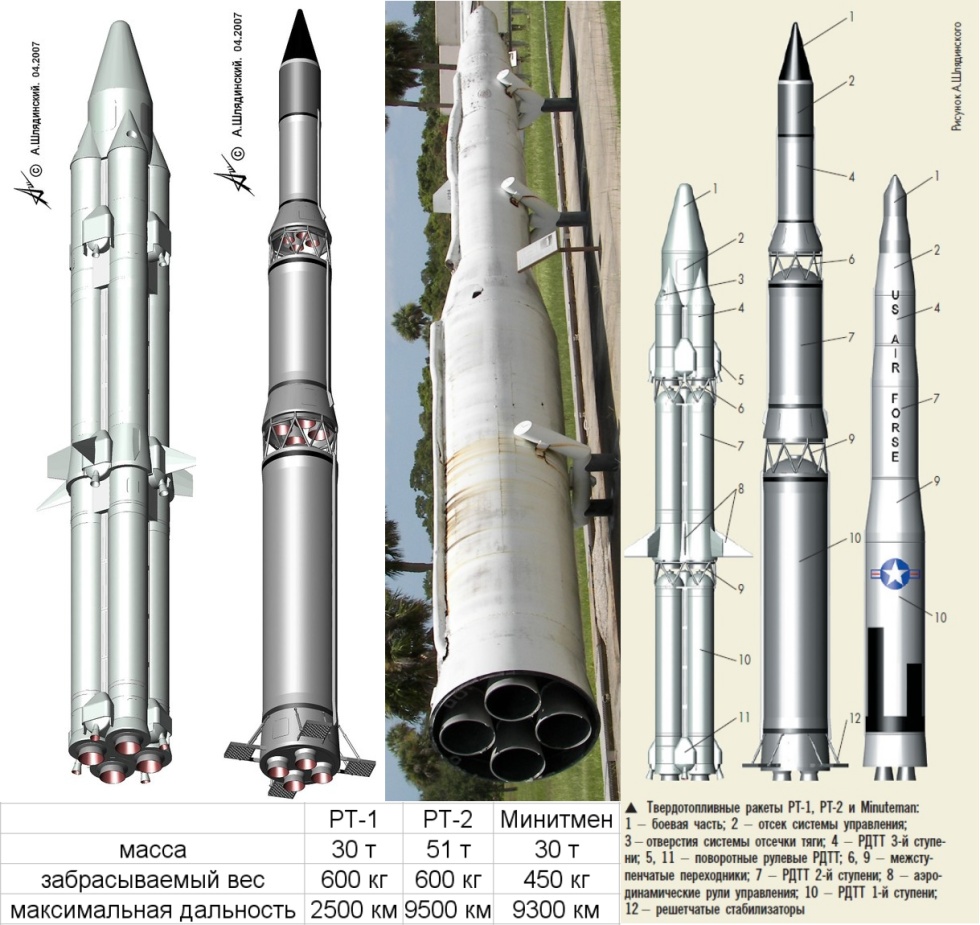

After medium-range missiles, the Minitman mixed-use ICBM was developed. Its advantages can be seen by comparing with similar Soviet projects. The fact is that in the USSR, Korolev tried to create a ballistic missile on ballistic gunpowder (RT-1) and on Soviet-style mixed fuel with worse performance (RT-2). Comparison of characteristics is very clear:

Please note that in the RT-1 rocket it was actually necessary to do an assembly of four separate engines due to restrictions on the diameter of the ballistic powder checkers. The RT-2 and the “Minuteman” have one big checker, but there are 4 nozzles in the first stage.

Features of solid fuel engines

Ability to create a very high thrust engine

The most powerful rocket engine in history was the Space Shuttle solid-fuel accelerator. Its initial thrust is 1250 tons, and the peak value reaches 1400 tons, which is approximately 1.8 times more than the thrust of the most powerful rocket engines (F-1 and RD-170). The most powerful of the engines in use is also solid propellant - these are the “Arian-5” side boosters, their thrust is 630 tons.

Traction profile is specified during design

LRE can be throttled - change the thrust, sometimes in a very large range. The solid-fuel engine burns uncontrollably, and the thrust can only be adjusted using the internal channel of a special profile. Different channel profiles allow you to have different traction profiles over time:

Inability to shutdown

After the solid-state solid propellant has turned on, it cannot be turned off. Explosive charges were placed on the side shuttles of the Space Shuttle so that in the event of a catastrophic failure they would not fly in an arbitrary direction. All flights of the shuttles took place with people, and the knowledge that a special person ( RSO ) was sitting in the bunker , who would explode the accelerators in the event of an accident, added to the nervousness. The Challenger side boosters in the 1986 crash were not damaged by a central tank explosion and were blown up a few seconds later.

Inability to restart

It flows from the previous paragraph. For each inclusion, it is necessary to have a separate stage with an engine. This is important for booster blocks, which should be included in space several times already.

Traction cutoff

If necessary, turn off the normally operating solid propellant rocket engine ahead of time (for example, when accelerating to the desired speed when shooting at an incomplete range), the only thing that can be done is the so-called traction cutoff. Special charges open the upper part of the combustion chamber, zeroing traction. The engine still works for a while, but the flame breaks out on both sides, which, in fact, does not add speed.

Lower specific impulse

The specific impulse (a measure of fuel efficiency) of a solid propellant rocket engine is lower than that of a liquid propellant rocket engine. This leads to the fact that in combat ICBMs usually one step more. Liquid UR-100 and R-36 have two stages, which is optimal for ballistics, and three stages are necessary for solid fuel "Topol". Therefore, mass perfection of solid propellant rocket motors is worse.

Easy to manufacture and operate

After pouring fuel into the combustion chamber, it becomes similar to rubber in consistency and does not require additional operations. Unlike booster blocks on the rocket engine, which must be refueled and checked at the spaceport, booster blocks with solid propellant rocket engines come ready from the manufacturer. Combat missiles with solid propellant rocket engines also come ready-made from the manufacturer and have been on duty for decades, without requiring additional fuel operations by personnel. In fairness, it should be noted that combat ICBMs with liquid propellant rocket engines also come from the manufacturer “ampouled”, without requiring refueling in the mine.

The complexity of management mechanisms

In the liquid propellant rocket engine, it is possible to select components after the TNA and use them in hydraulic steering machines to deflect the nozzle. There is no such possibility in the solid propellant rocket engine, therefore it is necessary to install powerful batteries or generators for steering cars. For example, on the Space Shuttle solid-fuel accelerator there were special gas generators that burned hydrazine from individual tanks and fed hydraulic steering machines that deflected the nozzle for flight control. Tanks with nitrogen tetraxide stood on the TTU LV Titan-4 , which was asymmetrically injected into the nozzle through controlled nozzles, creating a draft asymmetry.

Separate orientation engines for liquid fuel have to be installed on accelerating blocks, and stabilization by promotion is necessary for the duration of the engine operation.

The impossibility of regenerative cooling

The walls of the combustion chamber are isolated by fuel that has not yet been burned, this is an absolute plus of the solid propellant rocket engine, but the situation is opposite with the nozzle. The matter is complicated by the fact that the combustion temperature of solid fuel is higher, and the combustion products have a much greater erosion effect than in a liquid propellant rocket engine. The nozzle is corroded by combustion products, which further degrades the engine due to a violation of the geometric parameters of the nozzle. Without the flow of components with which the nozzle can be cooled, other methods have to be invented. There are two of them - cooling by radiation and evaporation (ablation). The critical section (the narrowest part of the nozzle, with the highest loads) is made of very hard and heat-resistant materials (specially treated graphite), the less stressed parts are made of heat-resistant materials. More details can be found here .

But these solutions come at a price - the solid propellant nozzle is heavier than the liquid propellant rocket engine. This is very clearly seen in the photographs from this hub :

On the left of the rocket engine, on the right of the solid propellant rocket engine

Conclusion

In modern rocket technology RTTT found four main niches:

- Military missiles. Solid propellant rocket engines provide high combat readiness, simplicity and reliability of engines of intercontinental and other missiles.

- Starting boosters. The ability to create a very powerful and cheap engine is used when it is necessary to take a more efficient but less powerful rocket engine from the ground.

- Acceleration blocks. The prevalence, simplicity, reliability, assimilation of industry, ease of storage led to the widespread use of solid propellant rocket motors as booster units in the United States. The specific momentum of the solid propellant rocket engine is only ~ 10% less than that of the heptyl / amyl pair (the mass of RB IUS is even less than Breeze-M due to the lower latitude of the cosmodrome), and one and a half times more efficient hydrogen / oxygen blocks were not used in Space Shuttle ", which recently launched a large number of satellites.

- Fireworks and rocket modeling. The simplicity of manufacturing a small solid propellant rocket propeller led to the fact that rockets are used in fireworks (there is almost certainly black gunpowder) and in rocket modeling. Simple home-made or purchased formulations (standard in stores) allow you to make small rockets for entertainment and training.

PS There will also be a third part. About types of liquid fuels, step sizes, launch facilities and money. Not very soon - through one article.