10 myths about home 3D printing

Interest in 3D printing is growing every day. There are more and more people who have at least heard of a 3D printer. More and more people are buying a 3D printer at home. But home 3D printing is still immersed in myths.

The situation is such that now the vast majority of 3D printers for home use work on FDM technology . Therefore, all myths will relate to this particular technology and are relevant only at the time of writing. The future is near, and the impossible today will be possible tomorrow.

So, 10 myths about home 3D printing that I often hear

1. You can print anything

This is not entirely true. With proper dexterity, you can really print a lot, but there are limitations:

- Printing is limited by print resolution.

It is not possible to print small parts that are smaller than the size of the nozzle. In addition, a problem arises when the previous layer does not have time to cool down and a new one is placed on top of it. The geometry of the object suffers from this. This problem is partially solved by forced cooling of the previous layer by air flow.

- The size and geometry of the object.

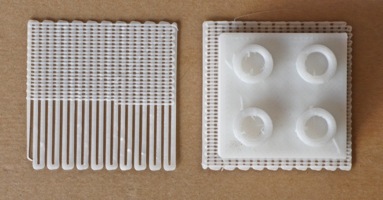

If the model has overhanging elements, support structures must be printed. Supports are difficult to remove if they are printed with the same material as the main model. This spoils the not-so-perfect surface.

It is also necessary that the model has a flat base, otherwise it will detach from the surface of the desktop. If the base of the model is non-flat or very small in size, then the model is printed on a special substrate - raft. Removing the raft also spoils the surface.

- The maximum dimensions of the print field.

There is a print working field. Model exceeding the dimensions of the maximum size of the print field at a time does not print. There is only one way out of this situation - you need to cut the model, print in pieces and glue the printed pieces.

2. Can print mechanisms assembly

Assembly mechanisms, for example a bolt on which a nut is screwed, is really possible. But not for FDM technology. Not exactly that accuracy. The nut and bolt fuse together. It is much easier to print the same bolt and nut separately.

Although, there are models of cars with spinning wheels and a whistle with a ball inside, which is broken off with a screwdriver.

3. Full color printing

About full-color printing at home so far you can forget. Printing with two (or more) colors is possible, but you need either several printheads, or change the bar during printing, or paint the bar itself. There are experiments on mixing colors, but they do not allow a sharp transition of color

4. The printed part is fragile

Of course, the printed model will be inferior in strength to the exact same cast model.

The strength of the printed part depends on where the force is applied: along the layers or across. In general, it resembles wood, the strength of which also depends on the force applied along or across the fibers.

In addition, the strength depends on the percentage of fill parts. A printed “cube” of 20x20x10mm with 100% filling is quite difficult to break with a hammer. In addition, everyone heard about the printed gun.

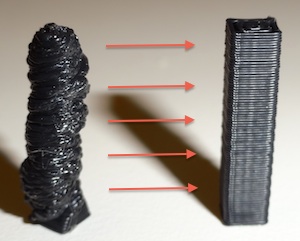

5. Printed models do not need processing

The surface of the printed model is not at all perfect: burrs, ribbing, sagging. To smooth the surface, mechanical (sanding, burr cutting) and / or chemical treatment (a bath with a solvent) is used.

6. Non-waste technology

Unlike a milling cutter, there is significantly less waste. After all, the object is created not by removing the excess from a single piece of material, but by building.

Nevertheless, the waste will still be:

- Plastic tends to leak out of the nozzle during downtime

- The percentage of defects can be very high (especially at the beginning of the path of a 3D printer)

- When the coil of plastic ends, there is a tail that is not enough to print anything useful

- Supports, substrates, skirts, which are then cut off from the printed model

7. The printer is cheap or vice versa

Of course, assembling a printer yourself is much cheaper. It is quite possible to keep within 15-25 thousand rubles. But this option is suitable for those who have time. Because part of the parts will have to be ordered from abroad.

Printers are assembled by hand, in particular because of this they are expensive. But value is falling and will continue to fall.

Again, everyone has different opportunities and for someone 40 thousand rubles. not money.

8. Everything is simple! Plug and print

This is the biggest misconception. Whatever the printer for 150 thousand rubles or 20 thousand will still have to "dance with a tambourine." If the printer is calibrated, you will have to select the slicer settings. For a good print you need to gain experience. It took me about six months to do this, along with the constant completion of my printer.

9. On 3D printing, you can make a good business

I want to disappoint those who are chasing money. There will be no huge profit, because there is not much demand.

Compete with large-scale products does not make sense. It’s much easier and cheaper to buy going to the store than to print it.

Printing is suitable for personalized objects (for example, a mug with your name), small-scale production (if the entire circulation will cost less than the mold for casting), prototyping (for which 3D printing was first used).

Again, the surface quality leaves much to be desired. And without post-processing, the item will not have a presentation.

10. A little more and everyone will have a 3D printer

To print something, you need a model. And here the printer user is faced with the choice to print ready-made models or simulate himself. The average user does not have 3D modeling skills. Print other people's models? Tired, no model needed.

And he would order this 3D model somewhere, but then print can be ordered.

In general, why buy a sewing machine and sew a shirt when you do not know how to do it and it’s easier / faster (sometimes cheaper) to order from the studio.

In addition, 3D printing still has a lot of problems so that the average user could not cope with them. But wait and see ...