Evolution of flexible displays

The dream of flexible screens has existed for many decades. Technically, the first screens on which movies were projected were initially flexible, they are still made of cloth. And yes, formally we already have displays that can be given any shape. But their resolution is extremely mediocre, the LEDs located on a flexible printed circuit board are used as pixels.

But science fiction writers have always dreamed of something else: they wanted a display thin and flexible like paper, with image quality like a good color photo. Alas, technology is hopelessly behind the human imagination. However, in recent years, from time to time, we are shown at exhibitions more and more perfect concepts, promising to “soon” establish mass production. And although we cannot yet wrap the smartphone around the wrist, we already have some history of flexible displays, and we decided to remember it.

A brief historical excursion

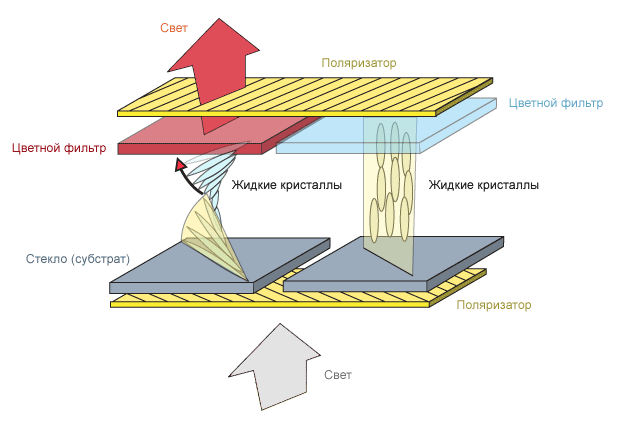

With the development of microelectronics, scientists were able to use the effect of unusual liquids, discovered in the late 19th century - “liquid crystals”. In the 1970s, technology was invented that made it possible to produce liquid crystals on an industrial scale, and the era of liquid crystal screens began. The simplest segment displays were widely spread, giving life to watches and other devices with LCD screens. Initially, liquid crystals in such screens were located in miniature cavities in packages of glass plates. Later, plastic was used instead of glass, and dreams of flexible displays began to come alive again.

Everything rested on the technology of manufacturing the substrate for the placement of the LCD and control electronics. It was not very interesting to make flexible segment indicators like those used in the clock, I wanted high resolution and color. This opportunity gave technology TFT - thin-film transistors. Liquid crystal shutters combined with TFT control logic made it possible to produce very thin screens, especially when compared to cathode ray tubes.

Flexible Screen Issues, E-Ink Technology

Unfortunately, the technology of the time did not allow to get rid of glass in the design of LCD displays, and this unpleasant fact for a long time pushed dreams of flexible screens.

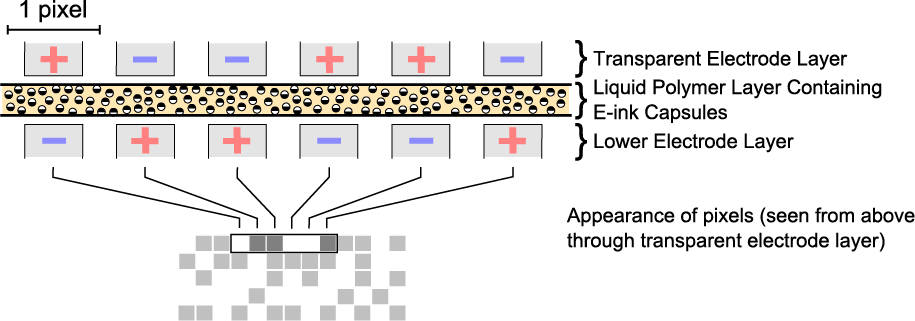

But science does not stand still. in search of new imaging techniques on displays, the technology of “electronic ink” was invented. The idea itself was proposed approximately when liquid crystal displays began to be mass produced in the 1970s. But it did not go further than the laboratory samples. The essence of E-Ink is very simple: in the thickness of the silicone sheet, in the cavities filled with oil, there are plastic spheres consisting of two parts: negatively charged - black, and positively charged - white. Transparent electrodes are placed on a sheet of silicone, which are divided into pixels, and their inclusion causes the spheres to turn by the black or white side, depending on the polarity on the electrodes.

Unfortunately, at the level of technology of that time, it was impossible to implement a high-quality E-Ink-display, and the technology was “delayed” for a couple of decades. In the 1990s, another technology was invented on a similar principle. The oil capsules remained, but the multi-colored spheres were no longer spinning in them, but the smallest charged particles, painted in black and white, were floating. When voltage is applied to the electrodes, these particles swim in accordance with their charge, and the front side of the pixel turns black or white.

And yet, before the industrial production of "electronic ink" there were still more than 10 years. In 2005, the company E-Ink began to massively produce displays for electronic readers. This technology has many drawbacks, but two advantages are decisive: extremely low energy consumption and the absence of complex elements in control. The first E-Ink-displays were made on glass substrates and were quite fragile, but gradually they began to abandon glass in favor of plastic, which made it possible to first make increasingly stronger displays, and then finally make the dream come true - to create a flexible display with quite decent by permission.

Such screens are not yet completely similar to paper or fabric, they cannot be creased, the radius of curvature is still quite large, they are quite vulnerable to mechanical damage, but they really bend and do not break from it.

OLED

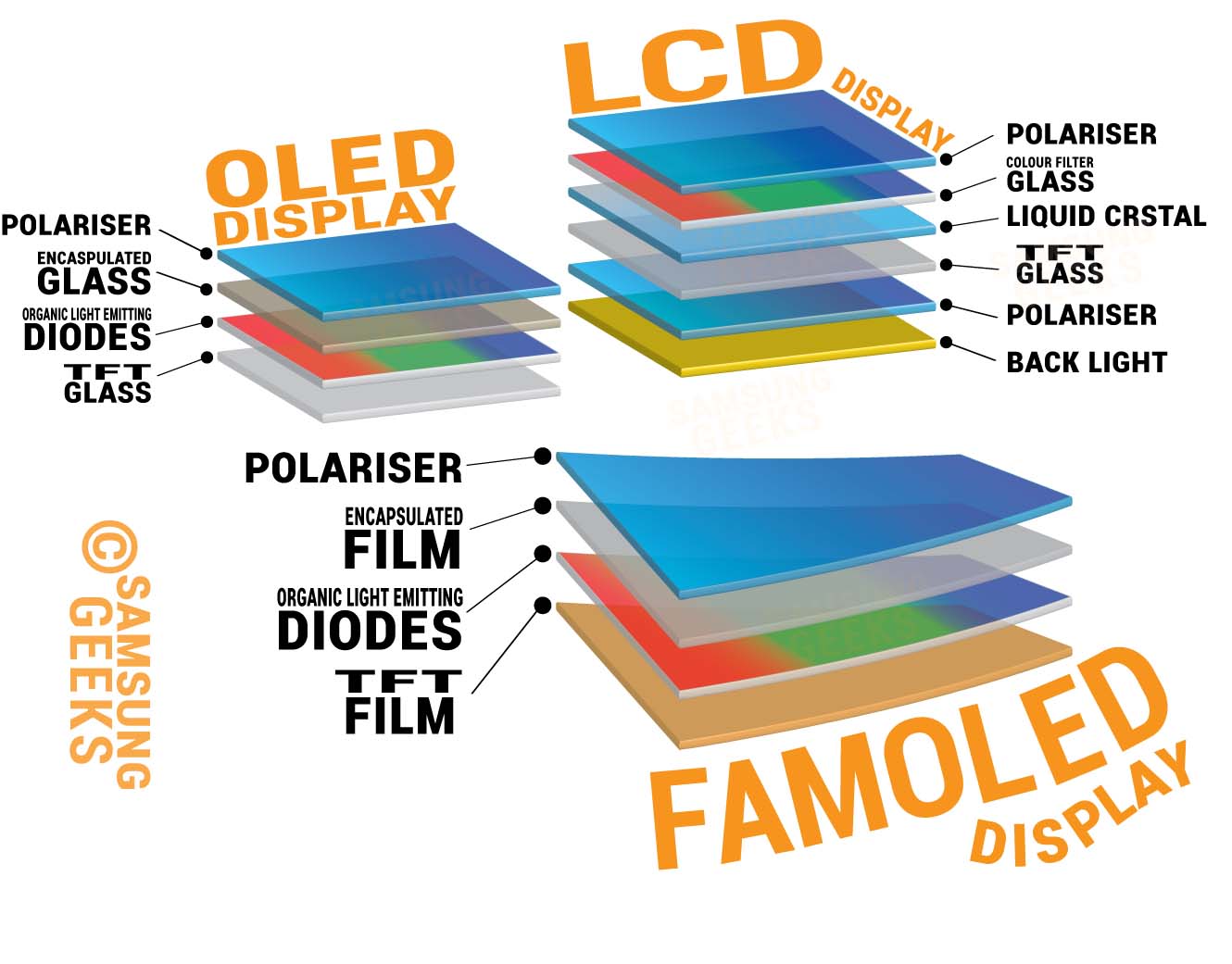

In the middle of the 20th century, organic substances were discovered that showed electroluminescence, but several decades of research were required before practical implementation. In the 21st century, the first OLED displays, manufactured on an industrial scale, began to appear. Initially, they were monochrome displays of portable devices, but in 2008, Nokia introduced the first phones with full-color OLED displays.

Unlike LCD screens, OLED is much easier to do without fragile elements; organic elements are located in layers of plastic, which bends much better than glass. Glass was used for strength in OLED displays, but it was successfully replaced with a flexible plastic or metal base.

Modern concepts

One of the earliest concept of a smartphone with flexible display was PaperPhone company's Human Media Lab , presented in 2011. As the name implies, the display was electronic ink. This device was first used a unique way to interact with the help of bending. Several sensors monitored the curvature of the display and, depending on the gestures, various actions were performed.

Later, we were shown a tablet with a flexible E-Ink-display and a completely unusual smartphone, MorePhone , which signaled notifications from programs by bending the case.

Nokia's Kinetic smartphone at Nokia World 2011, it was also controlled by body bends:

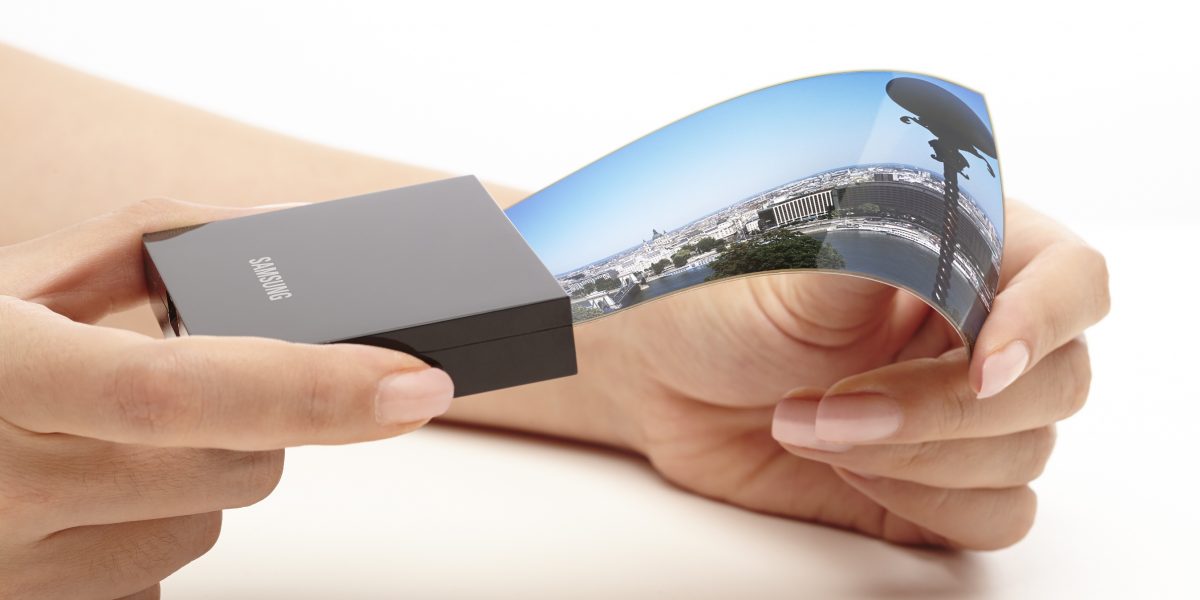

Samsung concept smartphone - YOUM introduced in 2013:

In 2014, Samsung introduced another flexible OLED screen:

In 2015, LG released a smartphone with a slightly curved display that could be “straightened out”:

In 2017, Sony demonstrated a curious watch, made from a solid E-Ink-display: The

dial and the bracelet are one piece, you can change their appearance separately.

Recently, Kyulux has introduced flexible PMOLED

displays : Monochrome, fluorescent displays with a diagonal of 1.74 inches and a resolution of 256x64 pixels will be sold later this year. This year, Tianma demonstrated a flexible AMOLED display with a hinge:

Diagonal 5.99 inches and a resolution of 1440x2280 pixels. The displays will be sold to ASUS and Lenovo for their new smartphones.

I would also like to mention two interesting technologies, even if they do not involve the use of flexible displays. The first is to project an image onto a screen of arbitrary curvature. The parameters of the surface on which the projector will shine are entered into the program, and the picture is distorted in such a way that the resulting image on the surface appears flat and even:

The second option is to project the image directly onto your hand. Video capture sensors track finger movements and touch on a specific area of skin, turning the human body into a touch screen:

Afterword

Now more and more companies are announcing the serial production of smartphones and other devices in flexible displays, from rings and bracelets to clamshell phones. Samsung and Apple pack patents on the use of flexible displays, showing renderings one more original than the other. But the scenarios of their use, at the current level of technical development, it seems to me, look ridiculous and far-fetched. Even simpler solutions, when the display does not bend in the process of using the gadget, but is curved initially, have a very dubious practicality, design for the sake of design. More or less successfully managed to introduce and justify in curved TVs of large diagonals, but the curved edges of the displays of the smartphone look like a purely design decision, for the sake of a beautiful view on the shop window and bright renders. While the displays are not so plastic and reliable, so that it is possible to embed articulations in them with a small radius and a resource of many thousands of bends. As a result, as their main advantage of flexible displays, their strength is called today, because elasticity allows them to withstand stronger mechanical effects:

It seems to me that as long as technology does not allow the display to be made soft and durable as a cloth, for placing them on clothes or on the body, there will not be much benefit from flexibility.