Solder the connector in 4 hours. Accelerated video

I often do RS-232 exchange sniffing. Usually they do it like this - you need two ports, one of which listens to the exchange “there”, and the other “here”. For two years, a device assembled from a pair of modules and a MAX232 soldered on a breadboard served for this purpose . The device allows you to work with both conventional RS-232 levels and TTL, the choice of operating mode is provided by a bunch of jumpers.

The problem was that the data is buffered before it gets to the computer via USB, which causes the data sequence to be distorted during sniffing. Let's say we sniff it like this:

- Hello!

- Great!

- Will you have a beer?

- No, today I only drink juices.

And we see this:

- Hello!

- Great! No, today I only drink juices.

- Will you have a beer?

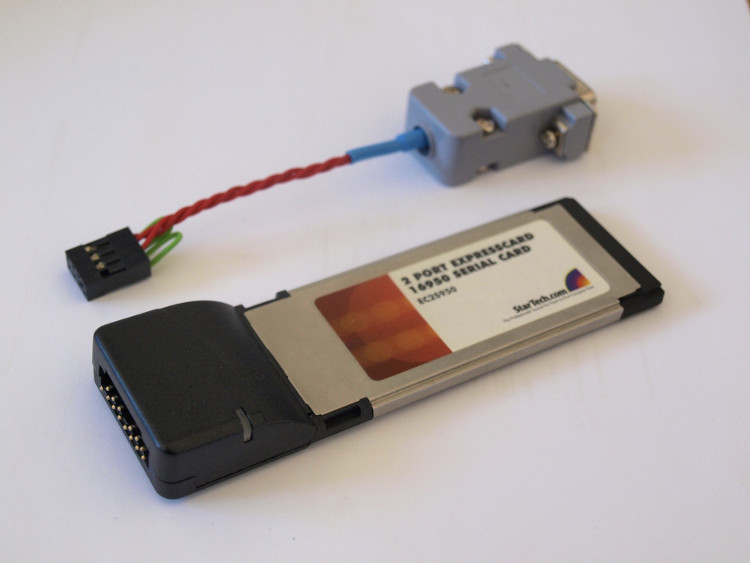

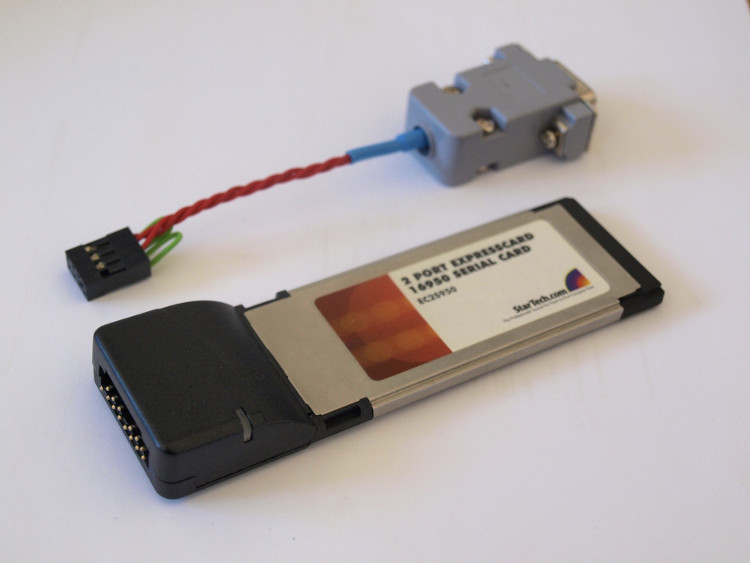

Since it is a laptop, all hope for an Express Card is a com-port card. Moreover, it should be an “honest” com port, and not USB (Express Card slot also hides USB). At the time of writing, a 2-port Oxford card on ebay.com cost about $ 35 with shipping.

I don’t remember what prevented me from just buying one, it seems that at that moment they were twice as expensive. I bought another , poyuzanny, without cable and for $ 25. The plan was to stick to it a connector from standard 2.54 mm pins and at the same time output signals with TTL levels to this connector.

In the TTL card, the signal is broken between the controller (in this case, OX16PCI952) and the level converter, two wires are output to an external connector. If we need a TTL level, we just connect to the desired pin. If you need the RS-232 level, then we hang up a jumper on the external connector, the signal is returned to the converter and, in RS-232 form, comes out already on the other terminal of the connector.

2 ports * 2 signals * 2 wires each = 8 wires to be soldered. This is for TTL signals. And 4 more for RS-232. At first it seemed to me that there shouldn’t be so many :)

If it’s interesting for habrazhitel, I can replenish the article with a detailed description of the process, but for now let the video tell everything. There are 4 hours, 20 times accelerated to 12 minutes. In general, the process took two (incomplete) days off. And one more evening (not reflected in the video) for soldering and soldering everything all over again - when it turned out that the board, in the places where I drilled it, was supplied with power in the middle layers.

I cannot recommend such a thing to someone else - during the same time it was possible to use a LUT printed circuit board and make a neat external level converter on the planar MAX232. And here is still a very low-tech process - to raise your legs, solder to the platform under them. Especially when you consider that during the soldering process, one contact pad fell off altogether and had to be soldered to the controller’s foot (and his feet had a pitch of 0.4 mm). Nevertheless, the goal was achieved and got such a device:

"

"

The problem was that the data is buffered before it gets to the computer via USB, which causes the data sequence to be distorted during sniffing. Let's say we sniff it like this:

- Hello!

- Great!

- Will you have a beer?

- No, today I only drink juices.

And we see this:

- Hello!

- Great! No, today I only drink juices.

- Will you have a beer?

Since it is a laptop, all hope for an Express Card is a com-port card. Moreover, it should be an “honest” com port, and not USB (Express Card slot also hides USB). At the time of writing, a 2-port Oxford card on ebay.com cost about $ 35 with shipping.

I don’t remember what prevented me from just buying one, it seems that at that moment they were twice as expensive. I bought another , poyuzanny, without cable and for $ 25. The plan was to stick to it a connector from standard 2.54 mm pins and at the same time output signals with TTL levels to this connector.

In the TTL card, the signal is broken between the controller (in this case, OX16PCI952) and the level converter, two wires are output to an external connector. If we need a TTL level, we just connect to the desired pin. If you need the RS-232 level, then we hang up a jumper on the external connector, the signal is returned to the converter and, in RS-232 form, comes out already on the other terminal of the connector.

2 ports * 2 signals * 2 wires each = 8 wires to be soldered. This is for TTL signals. And 4 more for RS-232. At first it seemed to me that there shouldn’t be so many :)

If it’s interesting for habrazhitel, I can replenish the article with a detailed description of the process, but for now let the video tell everything. There are 4 hours, 20 times accelerated to 12 minutes. In general, the process took two (incomplete) days off. And one more evening (not reflected in the video) for soldering and soldering everything all over again - when it turned out that the board, in the places where I drilled it, was supplied with power in the middle layers.

I cannot recommend such a thing to someone else - during the same time it was possible to use a LUT printed circuit board and make a neat external level converter on the planar MAX232. And here is still a very low-tech process - to raise your legs, solder to the platform under them. Especially when you consider that during the soldering process, one contact pad fell off altogether and had to be soldered to the controller’s foot (and his feet had a pitch of 0.4 mm). Nevertheless, the goal was achieved and got such a device:

"

"