The other side of 22nm: the unknown heroes of Silicon Valley

Every few years, Intel announces a transition to a new process. If you add news from other semiconductor companies here, then a year does not pass so that one or another of them does not announce a new breakthrough. The names of these companies are well known and are well known to everyone. But in their shadow (completely undeservedly) one company was lost, the work of which is invisibly behind almost every technological achievement in semiconductor technology. "The country must know its heroes" ...

It's about the little-known company Applied Materials, which has simply been doing its job for over 45 years. And today, at every silicon chip manufacturing plant of Intel, TSMC, Global Foundries, and almost any other, Applied Materials equipment is installed, which performs almost the smallest work known to mankind. At the same time, the matter is not limited to the production of microcircuits, Applied Materials also had a hand in the production of liquid crystal screens and solar panels. If a company is dealing with silicon wafers, it is almost 100% likely to state that Applied Materials equipment is responsible for most of the manufacturing process.

Company logo, who has ever seen it before?

In particular, when Intel announced the transition to 22 nm technology, it achieved this using Applied Materials equipment. This does not make Intel's achievement less outstanding: Applied Materials provides the equipment, but Intel has everything else from microprocessor design to finding the right chemistry. It is also important to note that AMD, Samsung and TSMC essentially have access to the same hardware as Intel.

What is it about microprocessor manufacturing?

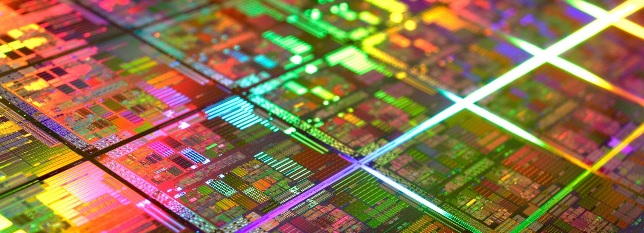

Many have heard about the lithography process. But if you think that the manufacture of a processor crystal consists only of it, then you are mistaken. Yes, lithography is a vital part of the process, but for modern technological processes 45nm and 32nm, not to mention 22nm Fin-FET, this is just one of hundreds of stages. After the silicon surface has been lithographed, transistors and their compounds are grown on it using a combination of galvanic processes, ion implantation, chemical deposition, molecular layering and many others. In addition, most of these operations can be broken down into dozens of steps.

There are many videos on the Internet that show microprocessor production (for example: this one ).

All these operations are performed by more than one machine, for example, in order to create a FinFET transistor, at least seven different settings are required. It is necessary to move silicon wafers between these plants, and do this in a vacuum. When dealing with layers of high-k dielectric, which is only 10 atoms thick, even one extraneous atom can ruin the entire processor.

Installation for applying an insulating film to a glass surface in the manufacture of LCD screens.

In large factories, the entire process is almost completely automated - using software provided by Applied Materials. To get some idea of the scale: a factory operating with 300 mm diameter plates, according to different versions, costs from 5 to 15 billion dollars. Each Applied Materials installation is about the size of an office desk and costs between $ 2 and $ 6 million. With an average price of 4 million, this means that more than a thousand units can be located in one factory, and all of them are located in a clean room (with an area of several thousand square meters).

Fab 42 - Intel factory in Arizona ($ 5 billion), construction will be completed this year

Every whim for your money

If each manufacturing company has access to the same Applied Materials equipment, then where does such a monstrous difference in the technological processes used come from? Why is Intel switching to 22nm technology using FinFET while Global Foundries are stuck somewhere between 32nm and 45nm?

There are two reasons for this. The first, as already mentioned, Applied Materials provides equipment, but the development of a specific process remains with the chip manufacturer or factory. Intel can use 8 layers of metallization to connect transistors, and AMD only 6. Intel can detect a variant of hafnium oxide, which serves as a better dielectric than that used at TSMC, etc. Each microprocessor manufacturer uses the services of the best chemists in the world to stay on the cutting edge. And it is their job to understand the capabilities and limitations of the Applied Materials equipment and use it to get the best result.

Second, although Applied Materials supplies standard equipment - for $ 50 million you can buy a complete set and immediately start production using 45nm technology! But the company also works with specific manufacturers and provides the modifications they require. If Intel needs to change the shape of one of the nozzles, or improve the piezoelectric transducer - Applied Materials will be happy to take over this work. Something like a trip to a car dealership: the buyer may want to force the engine or tint glass. In essence, all cars are identical, but modified according to the wishes of customers.

Great section.

It turns out that Intel would not be able to reach the 22nm mark without close cooperation with engineers and chemists from Applied Materials. But, on the other hand, Applied Materials also knows the darkest secrets about the latest achievements of AMD. It is easy to imagine the scale of the conflict of interest that takes place here. What happens if one of the engineers accidentally gives out one of the secrets of FinFET technology to employees of another company?

To avoid such problems, Applied Materials has separate teams that work with each of the major customers and do not interact with each other. In theory, an Applied Materials engineer working with Intel will never meet an engineer working with AMD. If in the information space this is achieved by delimiting access rights and similar measures, then nothing is specifically known about the delimitation that occurs in the real world. Are there separate cafeterias and workrooms for each team? And does the Applied Materials campus in Santa Clara look like a palace from one children's book? :) Considering that Applied Materials has been working in this way for more than 40 years, they probably know how to convince their customers of the reliable protection of their intellectual property.

Who will remember from which book this palace? :)

This level of cooperation and trust allows Applied Materials to enter into multi-billion dollar agreements on the creation of equipment and the exchange of intellectual property. And only thanks to this technology 22nm, 14nm and, in the near future 10nm, are born.

22nm and farther

Undoubtedly, we are already approaching the limits of silicon electronics capabilities (the distance between two silicon atoms is 0.5 nm). But technologies such as multi-patterning, immersion lithography and FinFET transistors allow us to expect the appearance of 14nm and 10nm processors in the next few years.

As the size of the transistors decreases, the accuracy of operations for their manufacture increases, and hence the cost of manufacturing a single plate increases. For example, when switching from 45nm to 14nm, the cost doubles due to the difficulties of creating FinFET transistors, an increase in the number of metallization layers, and the use of multi-patterning.

With all this, Applied Materials continues to do its part of the work, increasing the yield of suitable crystals and lowering the price.

For example, the next generation of equipment will be designed to use plates with a diameter of 450 mm. That will reduce the cost of a single microprocessor.

The increase in the diameter of the plates, the very first plates in diameter were only 25 mm.

Or, the creation of new approaches to the insulation of conductive bonds (in total, the microprocessor contains more than 100 km of copper wire, which is responsible for 30% of the energy consumption and heat dissipation of the crystal), which can be reduced by several percent total processor consumption. Not so bad when you consider that now one of the main metrics is battery life.

Here it is: Applied Materials. Silicon Valley's unknown hero, spearheading the advancement of semiconductor electronics even before Intel launched its first microprocessor.

Judging by the current state of affairs, experience and technology portfolio, the company is in excellent shape and is able to continue on its way to the limits of silicon electronics, and beyond.