Making flexible graphene ionistors using a conventional DVD drive

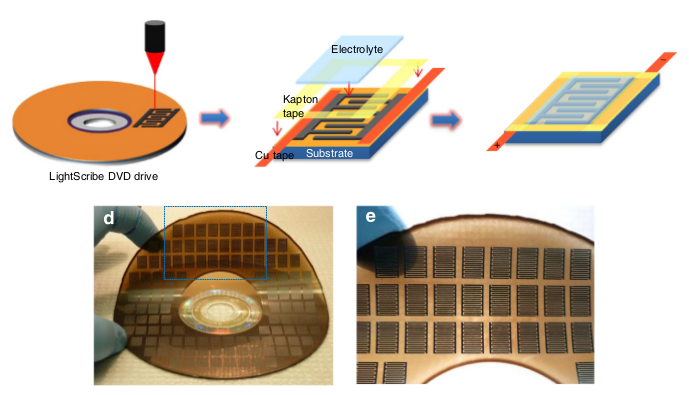

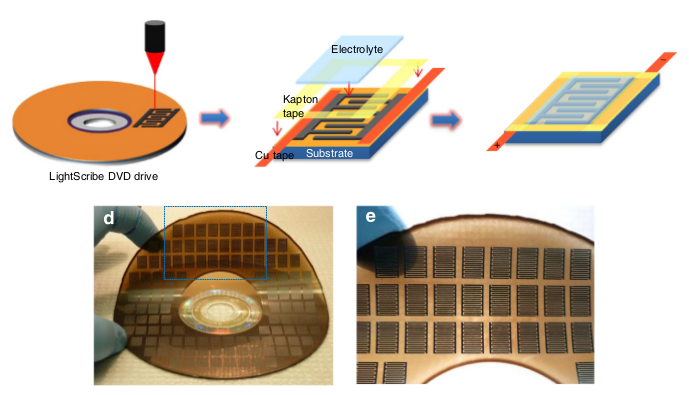

Scientists from the University of California at Los Angeles have developed a way to produce thin and flexible graphene supercapacitors ( ionistors ) using a DVD writer that supports LightScribe. LightScribe technology was originally designed to print on the back of the disc. Scientists covered the disk with a layer of graphite oxide on a plastic substrate, and then burned out the outline of the ionistor plates with a laser drive. Under the action of a laser, graphite oxide turned into graphene, whose electrical conductivity is six orders of magnitude higher than that of graphite oxide. These graphene paths formed linings.

The plates are made in the form of two “combs” - the teeth of one are embedded in the gaps of the other. The thinner the teeth, the more energy such a flat ionistor can store. This design demonstrates much better characteristics than the more familiar “sandwich” of two sheets of graphene with an electrolyte between them. In addition, it is much more technologically advanced - both plates are created at the same time, after laser treatment it is enough to just cover them with a layer of electrolyte.

In laboratory samples, a power density of 200 watts per cubic centimeter was achieved. Like conventional ionistors, LSG (Laser Scribed Graphene) flat supercondensers withstand a huge number of charge-discharge cycles. Their characteristics practically do not change during bending and twisting. You can create such a supercapacitor with a laser on almost any surface - not only on a flexible film, but also directly on a silicon crystal. In the future, this will allow the creation of microelectronic devices with an integrated battery element directly on the chip.

Article in Nature (PDF) .

Video:

The plates are made in the form of two “combs” - the teeth of one are embedded in the gaps of the other. The thinner the teeth, the more energy such a flat ionistor can store. This design demonstrates much better characteristics than the more familiar “sandwich” of two sheets of graphene with an electrolyte between them. In addition, it is much more technologically advanced - both plates are created at the same time, after laser treatment it is enough to just cover them with a layer of electrolyte.

In laboratory samples, a power density of 200 watts per cubic centimeter was achieved. Like conventional ionistors, LSG (Laser Scribed Graphene) flat supercondensers withstand a huge number of charge-discharge cycles. Their characteristics practically do not change during bending and twisting. You can create such a supercapacitor with a laser on almost any surface - not only on a flexible film, but also directly on a silicon crystal. In the future, this will allow the creation of microelectronic devices with an integrated battery element directly on the chip.

Links and videos

Article in Nature (PDF) .

Video: