Simple Solder MK936 SMD. DIY soldering station on SMD components

- Tutorial

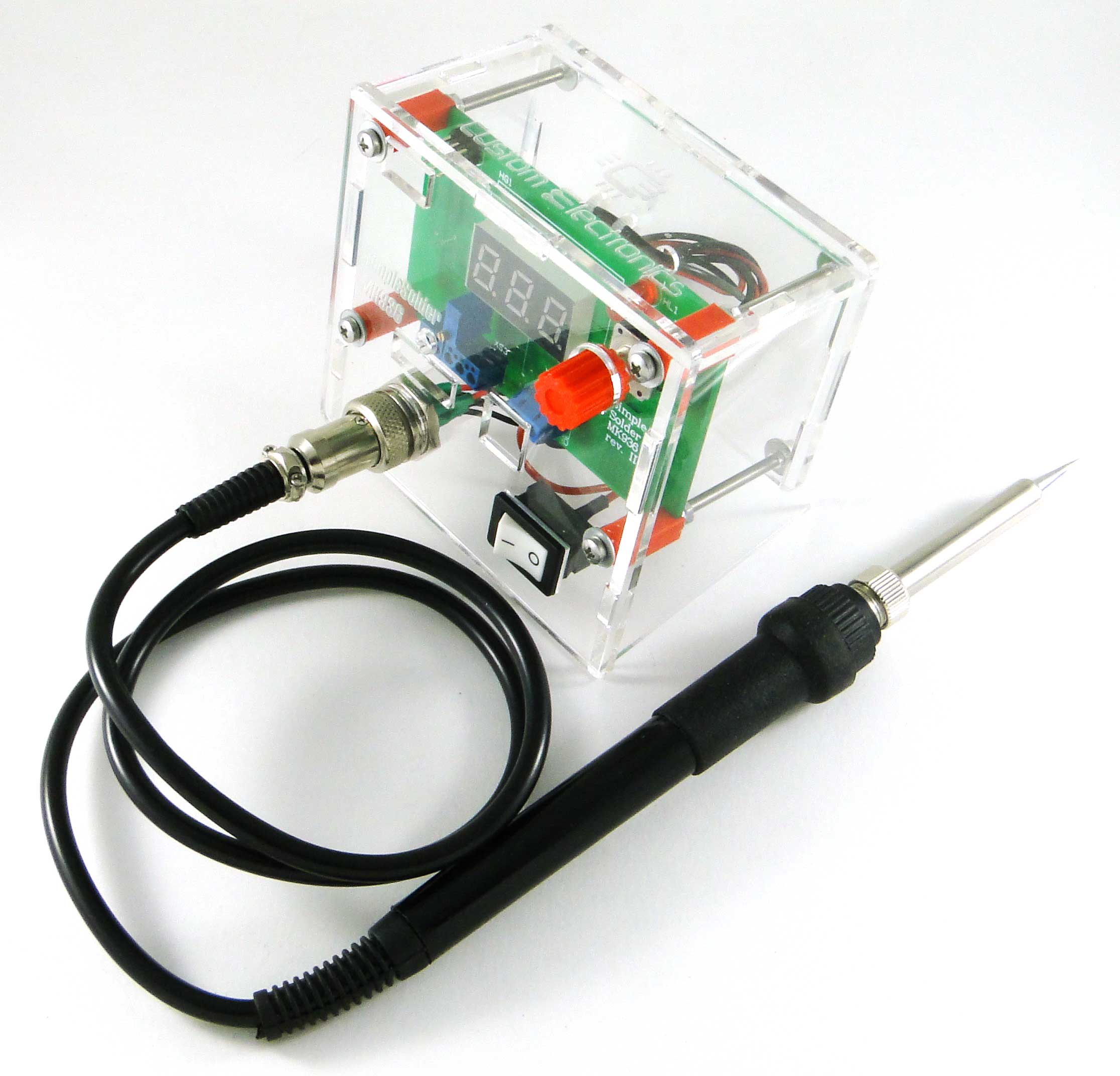

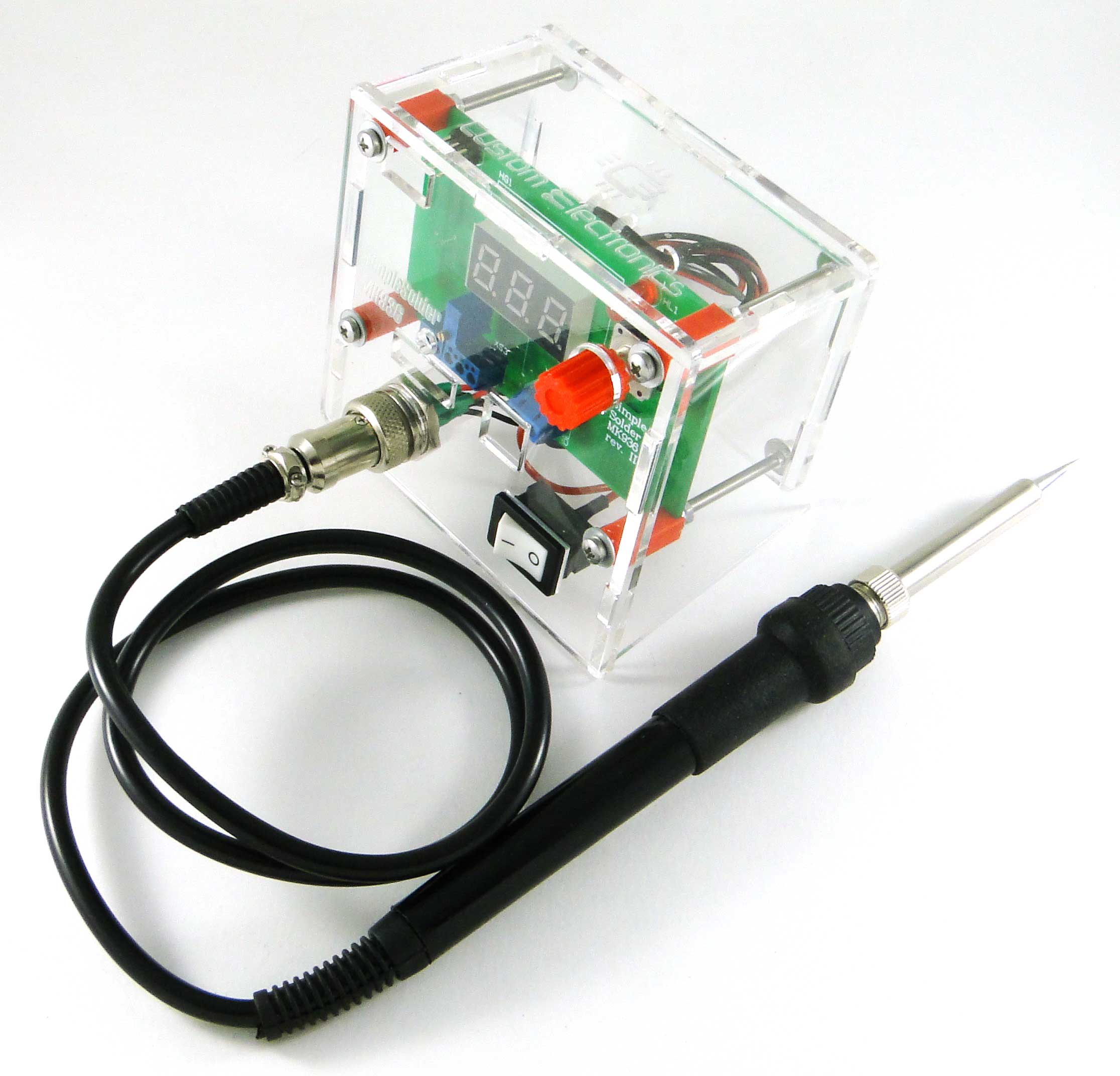

In this article we want to introduce you to the project of a soldering station, which everyone can assemble with their own hands.

It represents a soldering iron with a unit for setting and adjusting the temperature. In the article you will find diagrams, circuit boards, firmware for the microcontroller, as well as recommendations for assembly and configuration.

Having collected it, you will gain experience with components of surface mounting (SMD) and, of course, a useful device.

The soldering station differs from a simple network soldering iron in that it has temperature stabilization. And it is very important when working with various trifles. Network soldering iron always dissipates the same power. That is, if it lies on the spot, it can even heat up to 500 degrees, and when you start to solder, it cools sharply.

On the other hand, if a thermocouple is built into the soldering iron, then feedback can be arranged. This makes it possible to regulate the power on the heater in order to maintain a stable temperature.

Our goal was to develop a soldering station based on a common and cheap soldering iron with a thermocouple. It has the following characteristics:

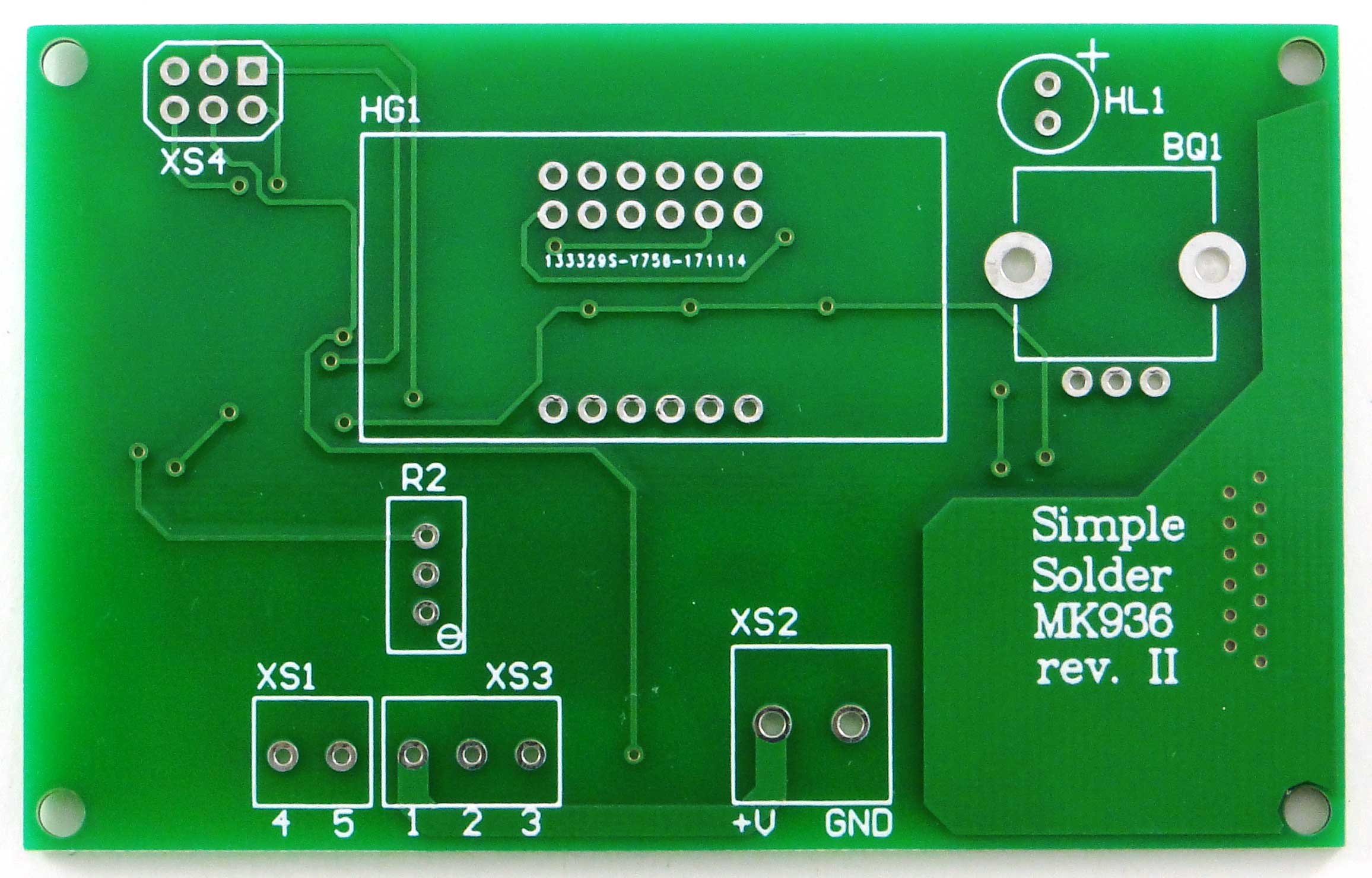

The board is double-sided, but adapted for manufacturing at home. At the end of the article you will find a link to the file for SprintLayout.

If you are interested in the scheme of the device, then you can find it here . On it, only the reference designations of the elements and pin numbers of the microcontroller differ. In fact, everything is done on an Atmega8 microcontroller, to which a seven-segment indicator, an encoder, a heater through a switch and a signal from a thermocouple, amplified by an operational amplifier, are connected.

The following components and materials are required to assemble the circuit board and case:

Here is a set of all the details:

When assembling, it is convenient to use assembly drawings: It is

necessary to begin with the installation of SMD components. Install elements on the board according to the list of elements. When installing elements, it is important to follow the orientation of the tantalum capacitors and the operational amplifier. The first conclusion DA2 is determined by the bevel on the body.

If everything is assembled correctly, the board should look like this.

Note that we used 1kOhm resistors without marking.

Next, you need to install the output elements on the board in accordance with the list of elements. Long LED output is a plus. The seven-segment indicator is set “points” down.

Here is the front side of the PCB assembly:

The power and soldering iron connection is made as follows:

Before assembling the case, it is necessary to prepare a switch and a connector. The switch must be connected to the break of the red wire so that on one contact of the switch there is a short piece of red thick wire, and on the second a long one.

You need to connect short red wires to the first and fifth pins of the soldering iron connector, and the rest are black.

Heat-shrink tubing should be worn on the switch and the connector and tinned all the free ends of the wires, so that later it was more convenient to screw them into the terminals.

Next, you need to install a switch and a soldering iron connector on the front panel. Please note that the switch can be installed tightly and it may be necessary to modify the slot for it with a file.

Then you should connect the first pin of the connector to the first pin of the board, the second to the second, and so on. in accordance with the above figure. To the power supply on the board, you must connect the red short wire from the switch, and the minus wire is the black wire.

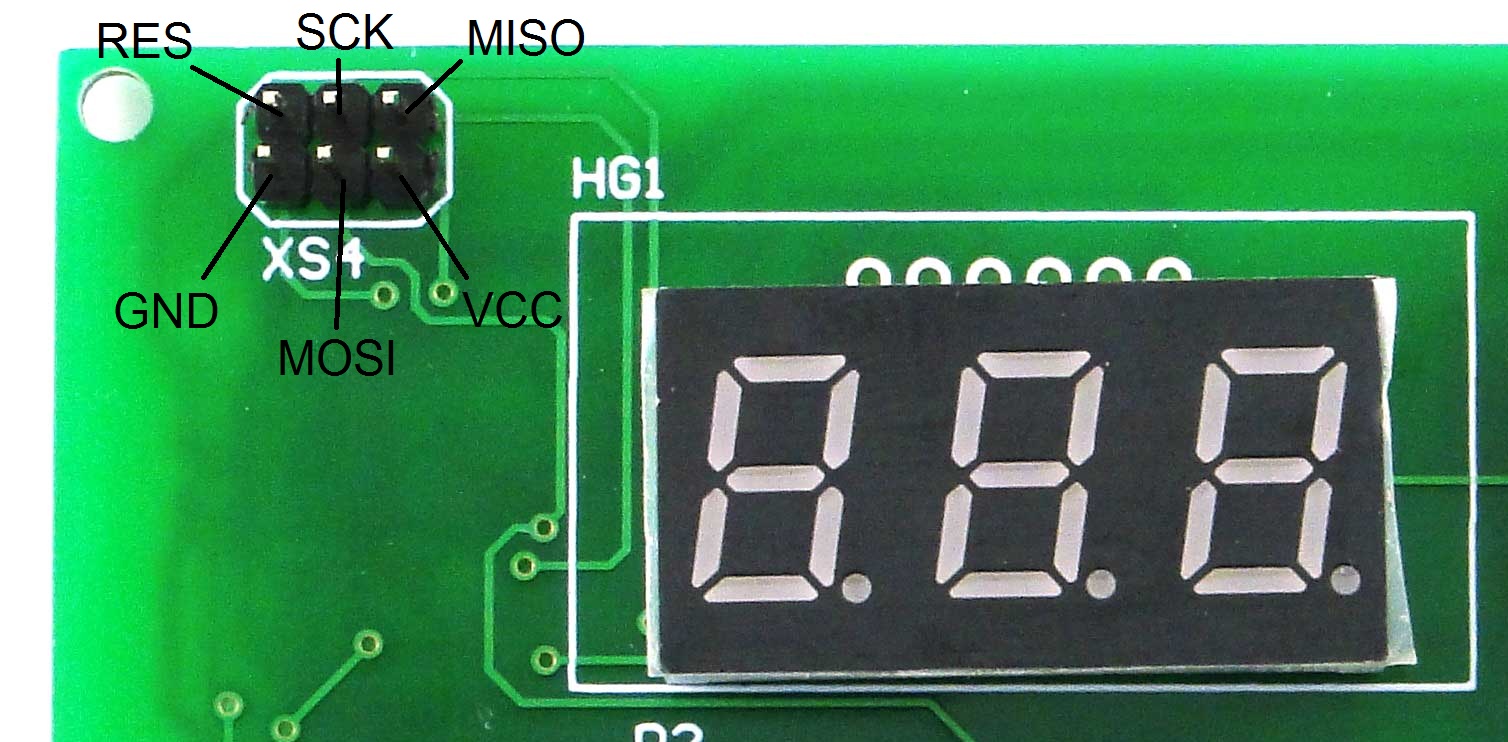

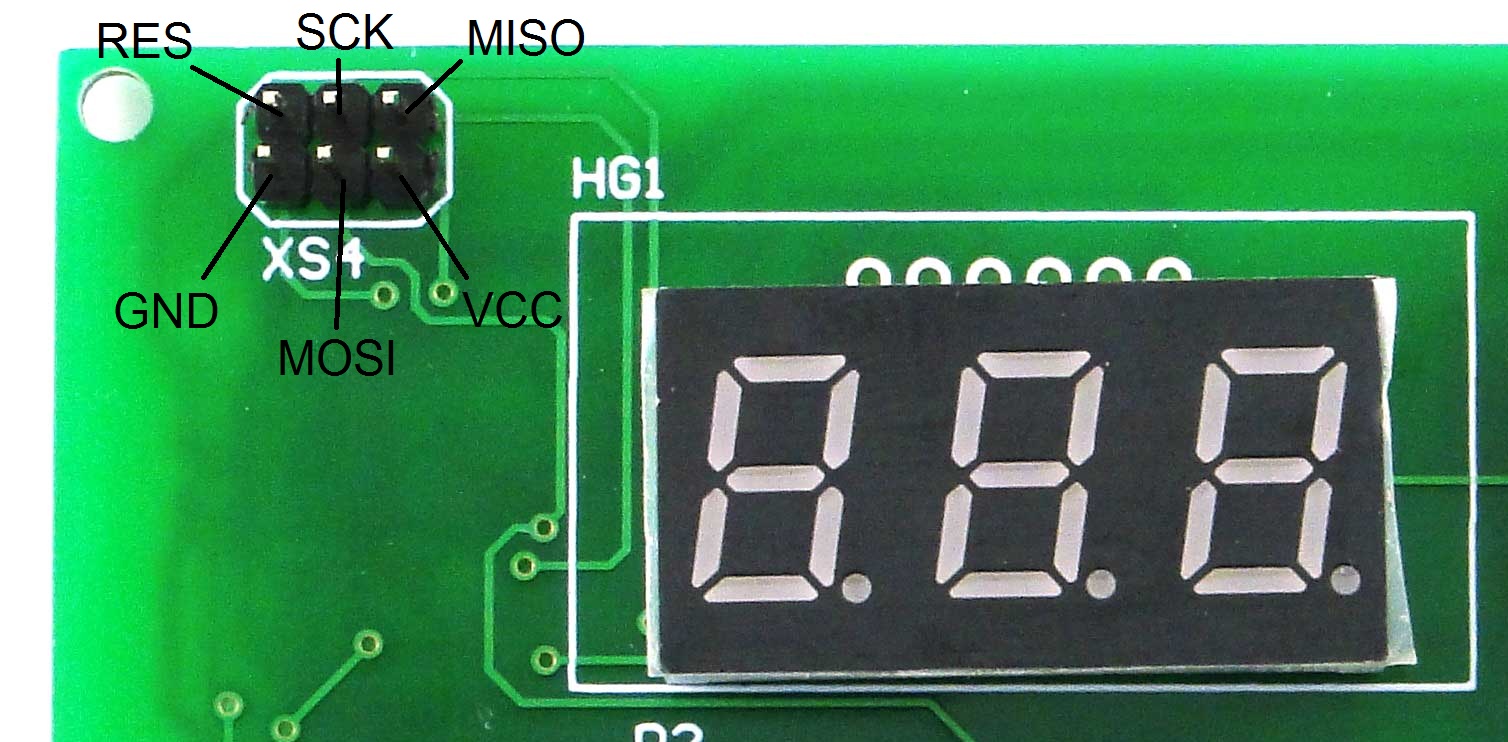

In the upper left corner of the board there is a standard ISP connector for flashing AVR microcontrollers.

You can flash the microcontroller with any programmer you have, for example USBasp. If the programmer provides power itself supplies 5V, then connect the external is not required. You can also find the firmware file at the end of the article.

Configuration bits! You must enable CKSEL0, CKSEL2, CKSEL3, SUT0, BOOTSZ0, BOOTSZ1 and SPIEN! That is, a change of default settings is required to start the controller at a clock frequency of 2 MHz.

Now you can connect a soldering iron and apply the input supply voltage (from 12 to 24V). After switching on, the soldering iron should begin to heat up, and the temperature reading on the indicator should increase. When the encoder shaft rotates, the value of the required temperature should change.

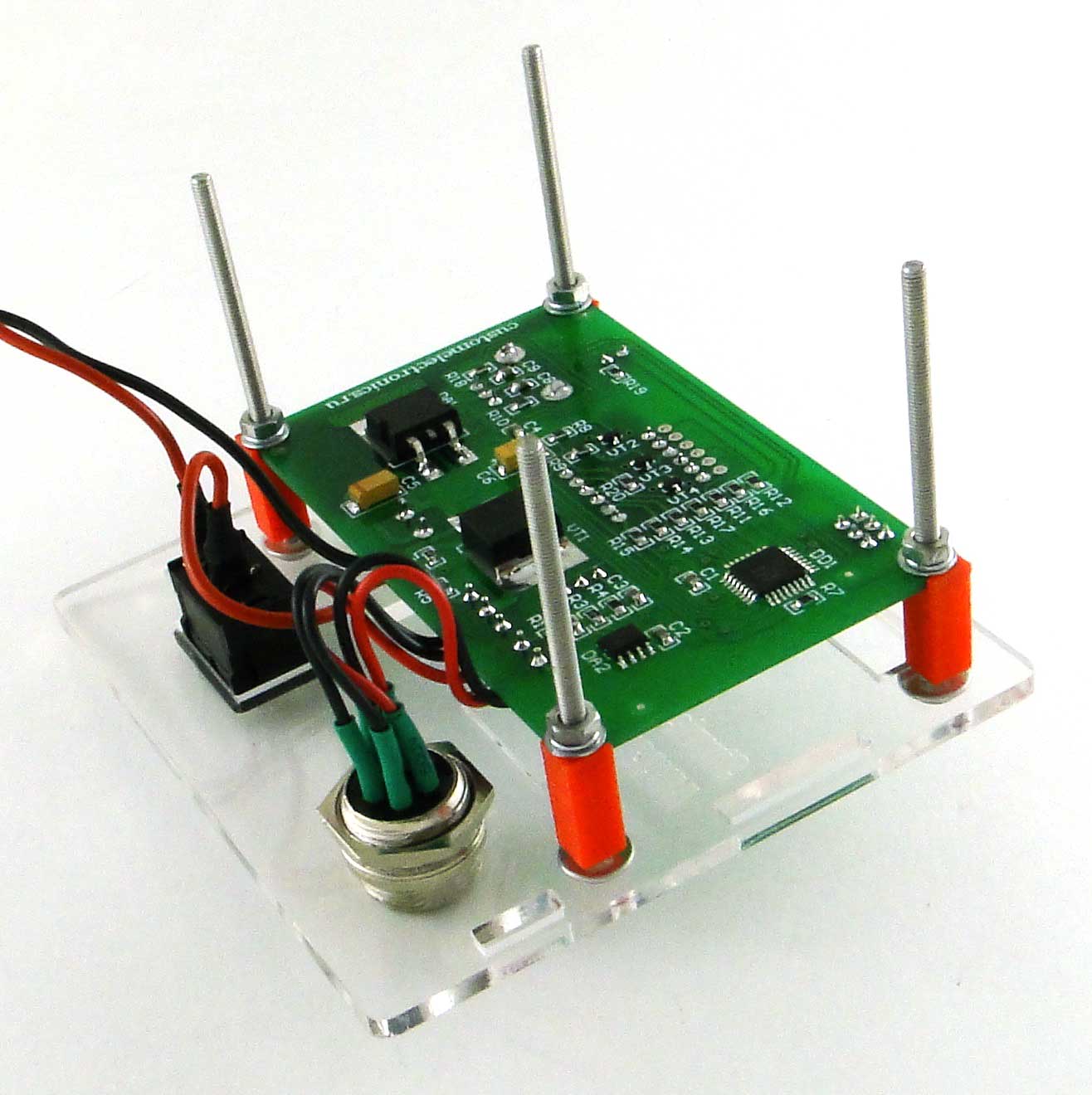

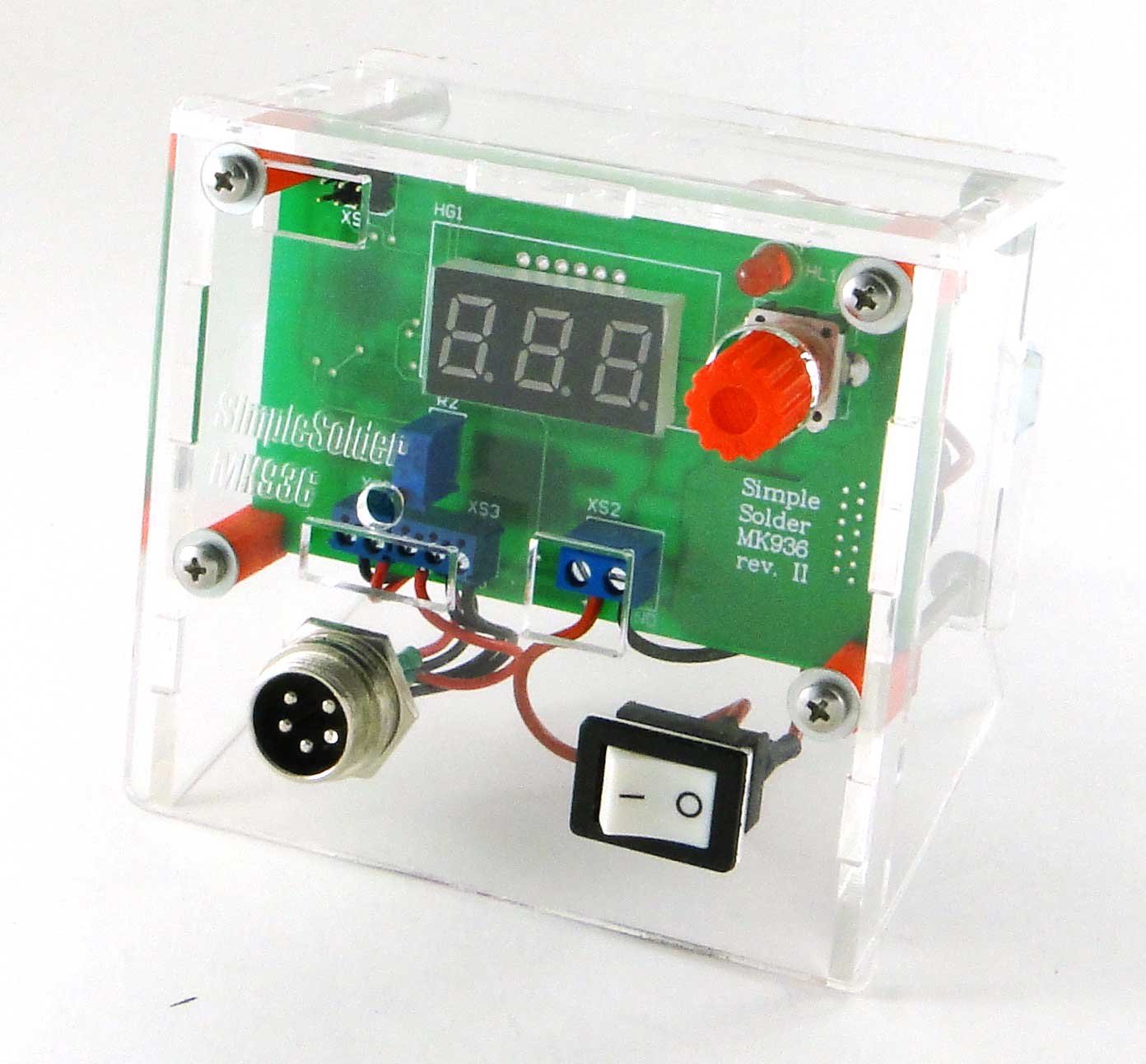

Now you can screw the board to the front panel. It is allowed to use conventional racks with a height of 10 mm, but we have prepared special racks that provide better fixation of the board. A model for 3D printing can also be found at the end of the article.

Side walls are installed without any mounts. Now it remains only to insert the back cover into the grooves, tighten the nuts, pull the power wires through the hole and fasten them with cable clamps. Remember that the plexiglass parts are quite fragile and do not overtighten the fasteners!

A trimmer is used to fine tune the temperature. The front panel has a special opening for access to it.

When calibrating, first of all it is necessary to bring the sting to the temperature at which the solder melts. You can simply set a very high temperature immediately with the encoder. Then, having collected a solder ball on a sting, it is required to warm up the thermocouple. There are special measuring devices for such purposes, but an ordinary multimeter with a thermocouple will do. Next, by rotating the trimming shaft, ensure that the measured value of the soldering station matches the readings of the external thermocouple.

During calibration, remember that the more time you give the soldering iron to stabilize the temperature, the more accurately you will be able to adjust it. Also note that the trimmer is multi-loop and one revolution changes the temperature very slightly. That is, you need to turn it boldly and a lot.

We also prepared a video instruction:

Direct links to all the necessary files for downloading can be found on the main page of the project .

This device also has a version on a single-sided board using only pin components. You can find it here.

Once again, I want to emphasize that we provide all the necessary and very detailed information for self-fabricating this device, and additionally provide the opportunity to purchase it in the form of a set ( one , two , three ).

PS: and we are also preparing a hairdryer) thanks for your interest in our activities!

It represents a soldering iron with a unit for setting and adjusting the temperature. In the article you will find diagrams, circuit boards, firmware for the microcontroller, as well as recommendations for assembly and configuration.

Having collected it, you will gain experience with components of surface mounting (SMD) and, of course, a useful device.

Description

The soldering station differs from a simple network soldering iron in that it has temperature stabilization. And it is very important when working with various trifles. Network soldering iron always dissipates the same power. That is, if it lies on the spot, it can even heat up to 500 degrees, and when you start to solder, it cools sharply.

On the other hand, if a thermocouple is built into the soldering iron, then feedback can be arranged. This makes it possible to regulate the power on the heater in order to maintain a stable temperature.

Our goal was to develop a soldering station based on a common and cheap soldering iron with a thermocouple. It has the following characteristics:

- Powered by a DC voltage source of 12-24V

- Power consumption, with 24V power: 50W

- Soldering iron resistance: 12Ω

- Time of an exit to an operating mode: 1-2 minutes depending on the feeding tension

- Maximum deviation of temperature in the stabilization mode, not more than 5 degrees

- Algorithm regulation: PID

- Display of temperature on a seven-segment display

- Heater type: nichrome

- Type of temperature sensor: thermocouple

- Temperature calibration capability

- Temperature setting with encoder

- LED to display the status of the soldering iron (heating / work)

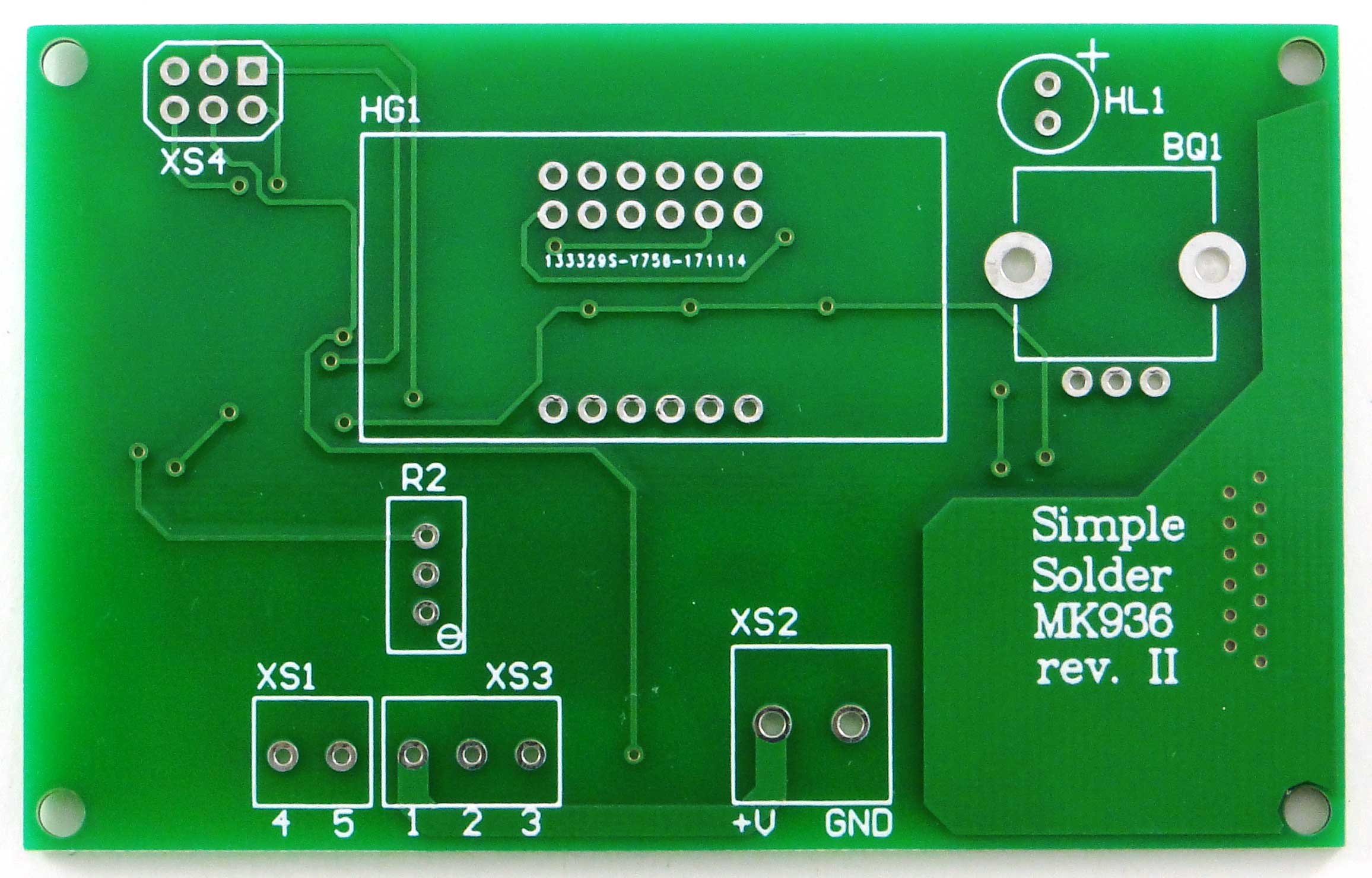

Printed circuit board

The board is double-sided, but adapted for manufacturing at home. At the end of the article you will find a link to the file for SprintLayout.

If you are interested in the scheme of the device, then you can find it here . On it, only the reference designations of the elements and pin numbers of the microcontroller differ. In fact, everything is done on an Atmega8 microcontroller, to which a seven-segment indicator, an encoder, a heater through a switch and a signal from a thermocouple, amplified by an operational amplifier, are connected.

Component List

The following components and materials are required to assemble the circuit board and case:

- BQ1. Encoder EC12E24204A8

- C5. Tantalum capacitor 35V, 10µF, size C

- C1-C4, C7-C9. Ceramic capacitors 0.1 microfarad in case 0805

- C6. Tantalum capacitor 16V, 22µF, size C

- DD1. ATmega8A-AU microcontroller in TQFP32 package

- DA1. Stabilizer L7805ACD2T-TR to 5V in the D2PAK package

- DA2. Operational amplifier LM358ADT in SO8 package

- HG1. Seven-segment three-digit indicator with a common cathode BC56-12GWA. Also, the board provides a seat for a cheap analogue .

- HL1. Any indicator LED for a current of 20mA with a terminal pitch of 2.54 mm

- R1, R6. Resistors 300 Ohm, 0805 body - 2pcs

- R4, R7-R20. Resistors 1kOhm, building 0805 - 15pcs

- R3. Resistor 100kΩ, body 0805

- R5. Resistor 1Ω, body 0805

- R2. Trimmer resistor 3296W 100kΩ

- VT1. Field effect transistor IRF3205SPBF in D2PAK package

- VT2-VT4. BC547BTA Transistors in the SOT323 package - 3pcs

- XS2. Two-prong terminal with lead pitch 5.08 mm

- Xs1. Two-prong terminal with lead pitch 3.81mm

- XS3. Three-prong terminal with lead pitch 3.81mm

- XS4. PLS-06 programming connector

- Connector for soldering iron

- Power Switch SWR-45 BW (13-KN1-1)

- Soldering iron . We will write about it later

- Details from plexiglas for the body (links to files for cutting plexiglass at the end of the article)

- Encoder knob. You can buy it, or you can print it on a 3D printer. File for downloading the model at the end of the article

- Racks. They can also be printed, but you can use ordinary sleeves with a hole of 3mm and a height of 10mm.

- Screw M3x60 - 4pcs

- Nut M3 - 8pcs

- M3 washer - 4pcs

- M3 washer increased - 8 pieces

- M3 horizontal washer - 8pcs

- Also required for the assembly of assembly wires, ties and shrink tube

Here is a set of all the details:

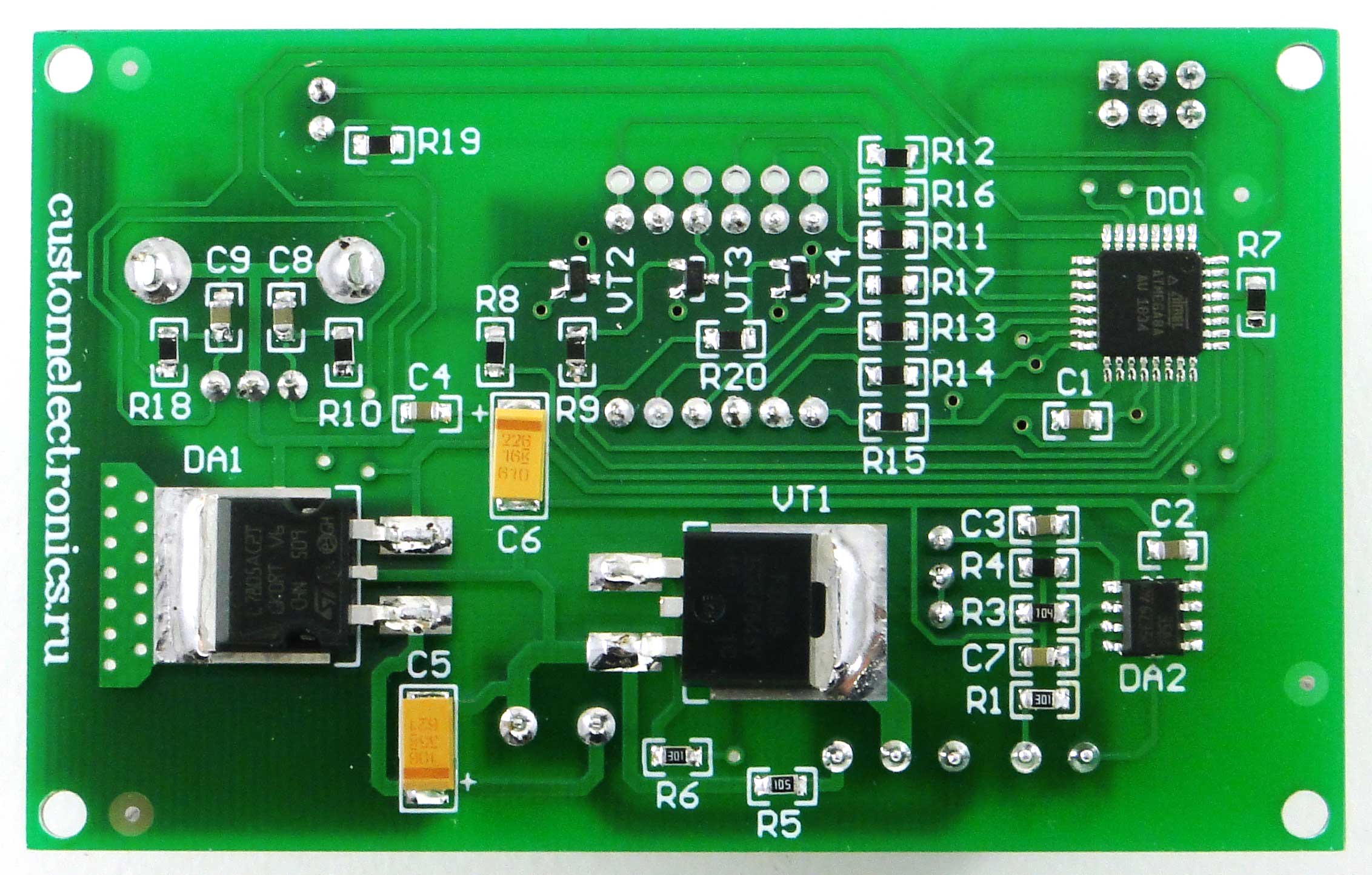

PCB Mounting

When assembling, it is convenient to use assembly drawings: It is

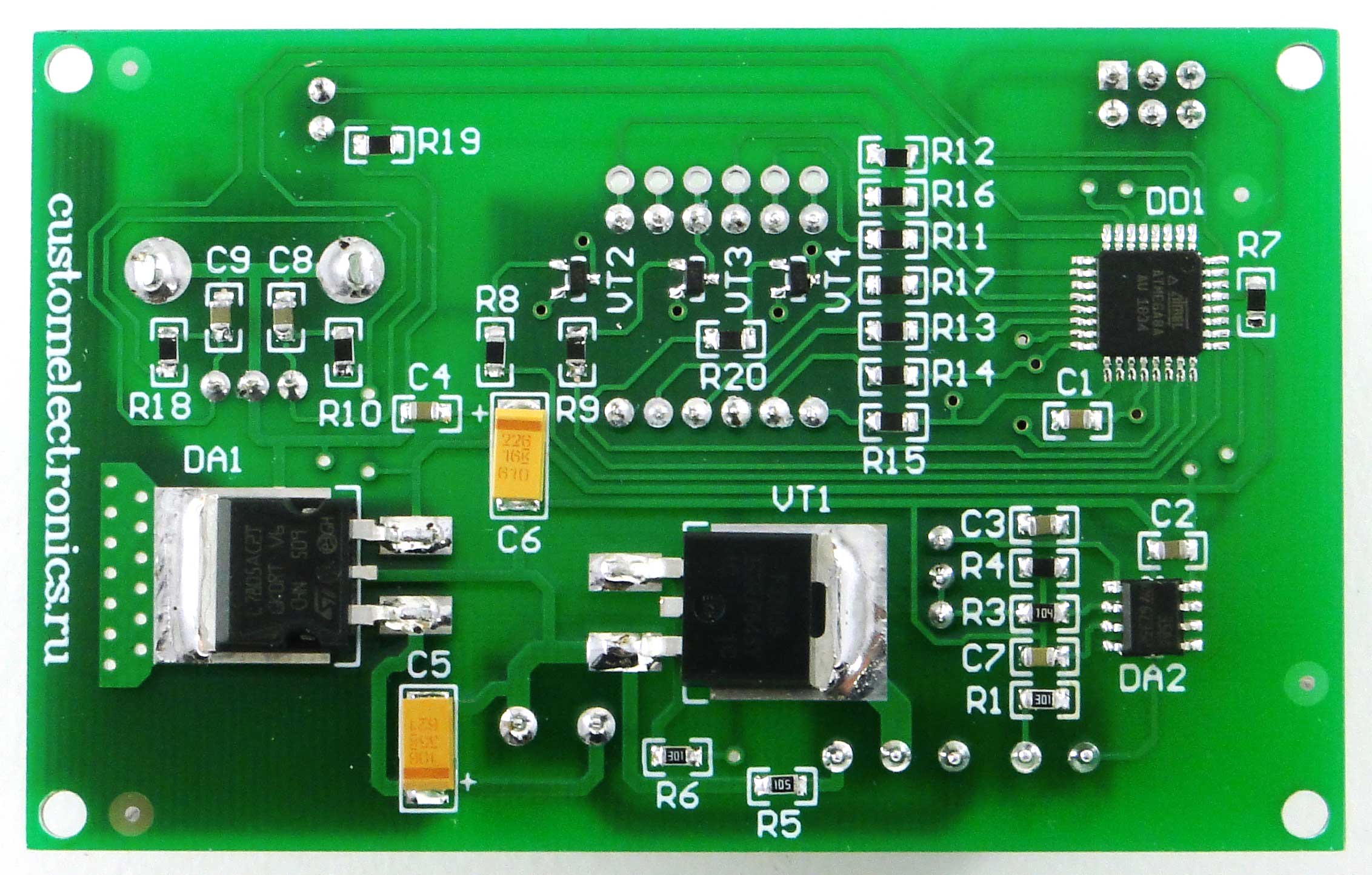

necessary to begin with the installation of SMD components. Install elements on the board according to the list of elements. When installing elements, it is important to follow the orientation of the tantalum capacitors and the operational amplifier. The first conclusion DA2 is determined by the bevel on the body.

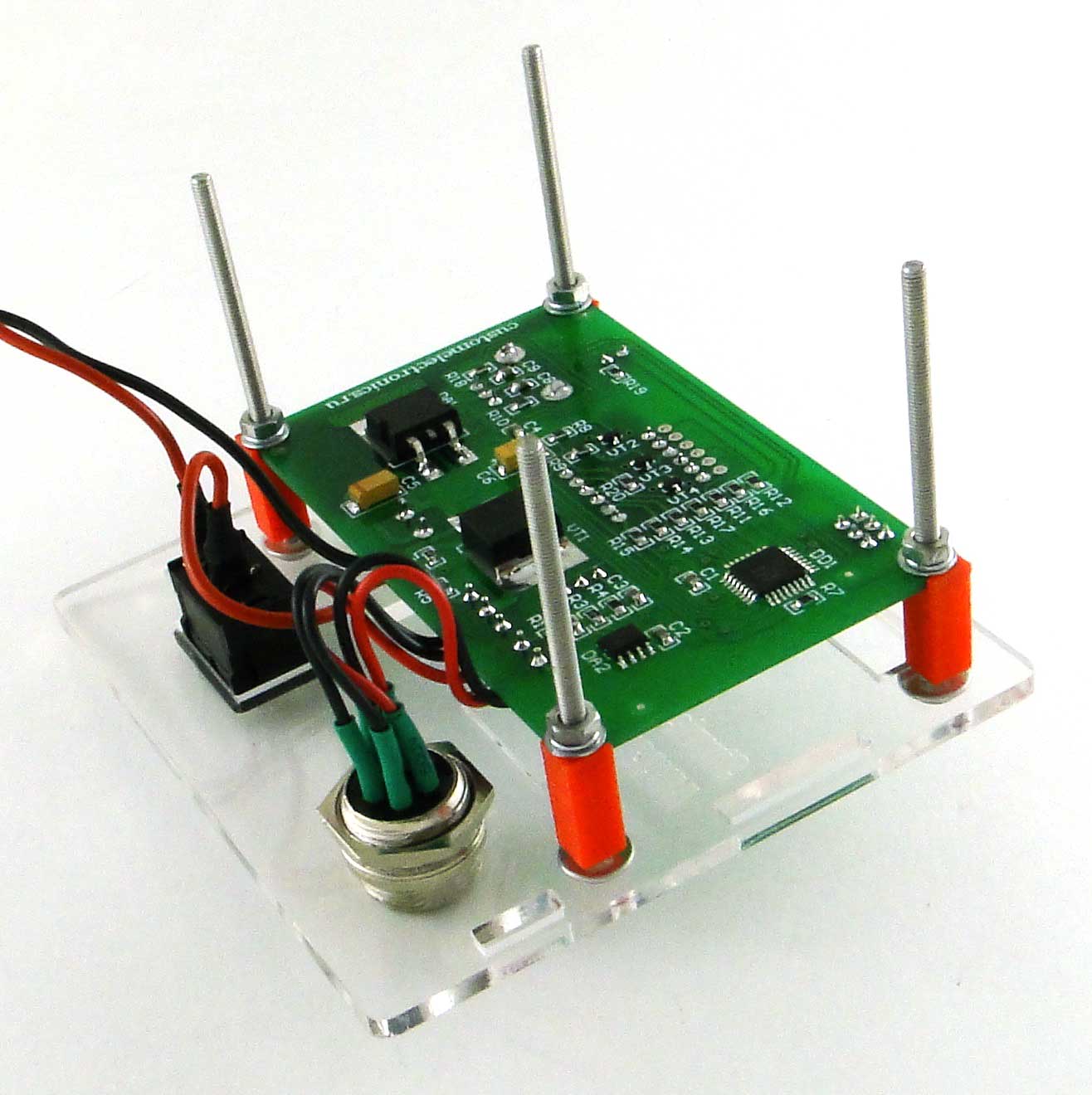

If everything is assembled correctly, the board should look like this.

Note that we used 1kOhm resistors without marking.

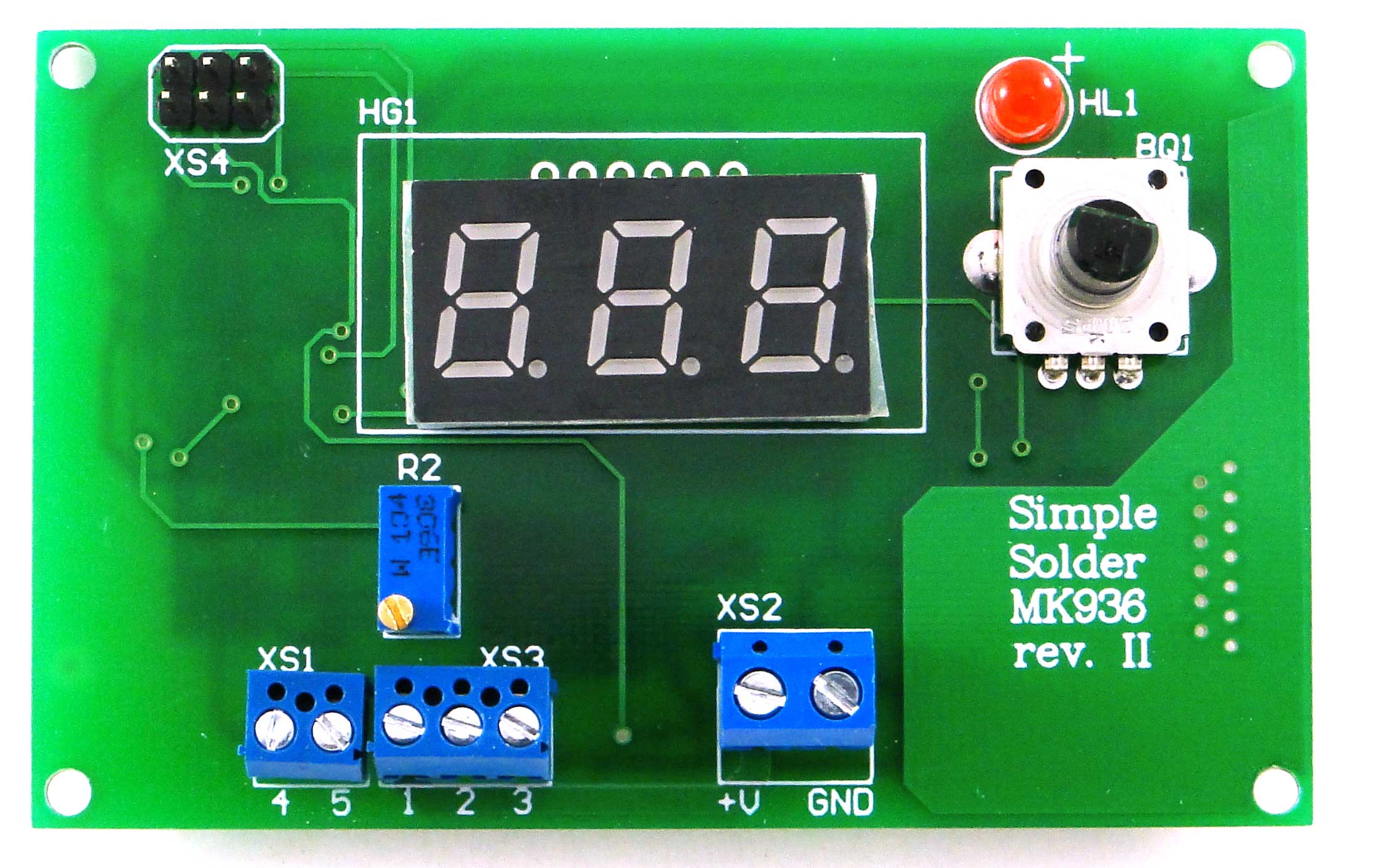

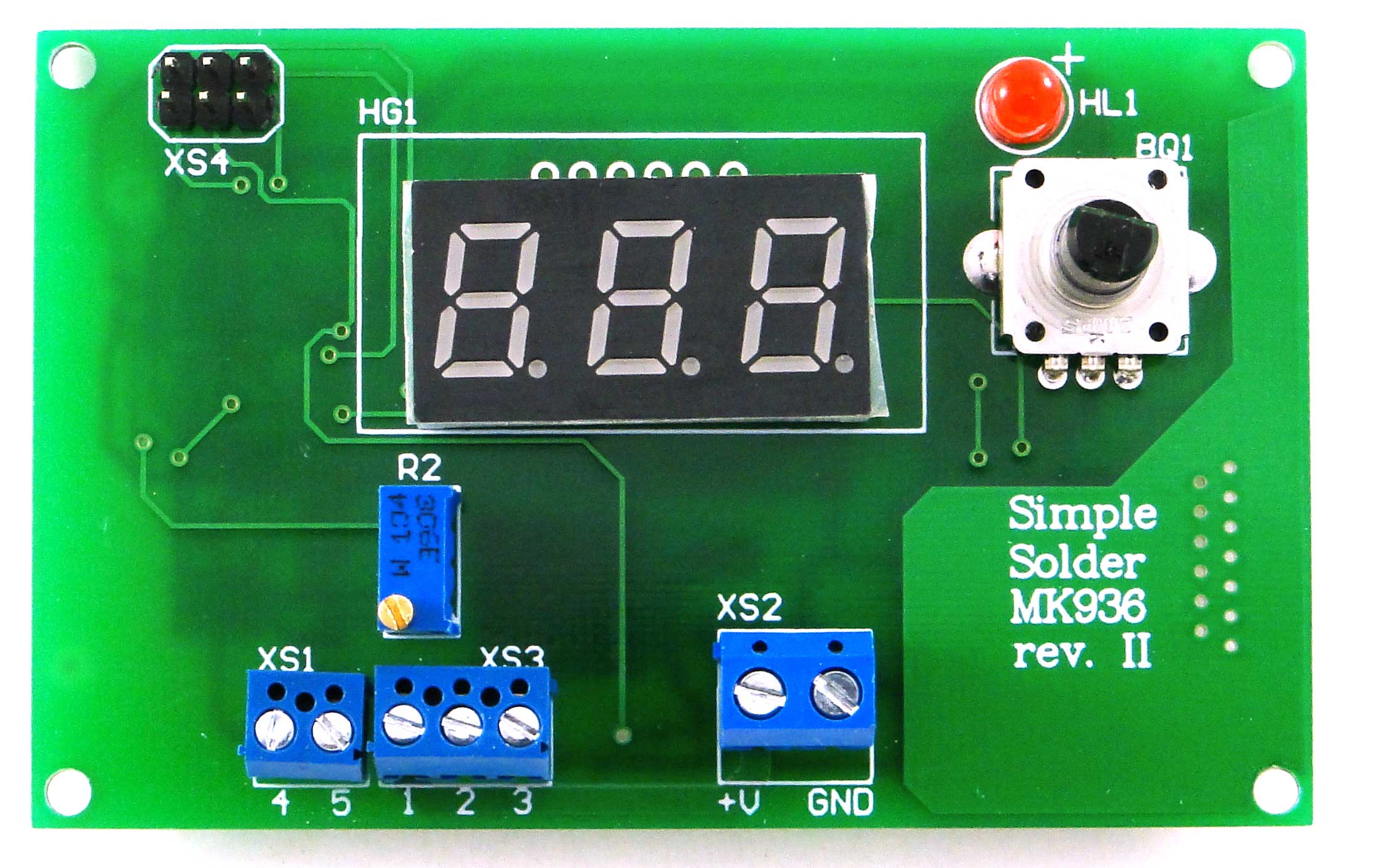

Next, you need to install the output elements on the board in accordance with the list of elements. Long LED output is a plus. The seven-segment indicator is set “points” down.

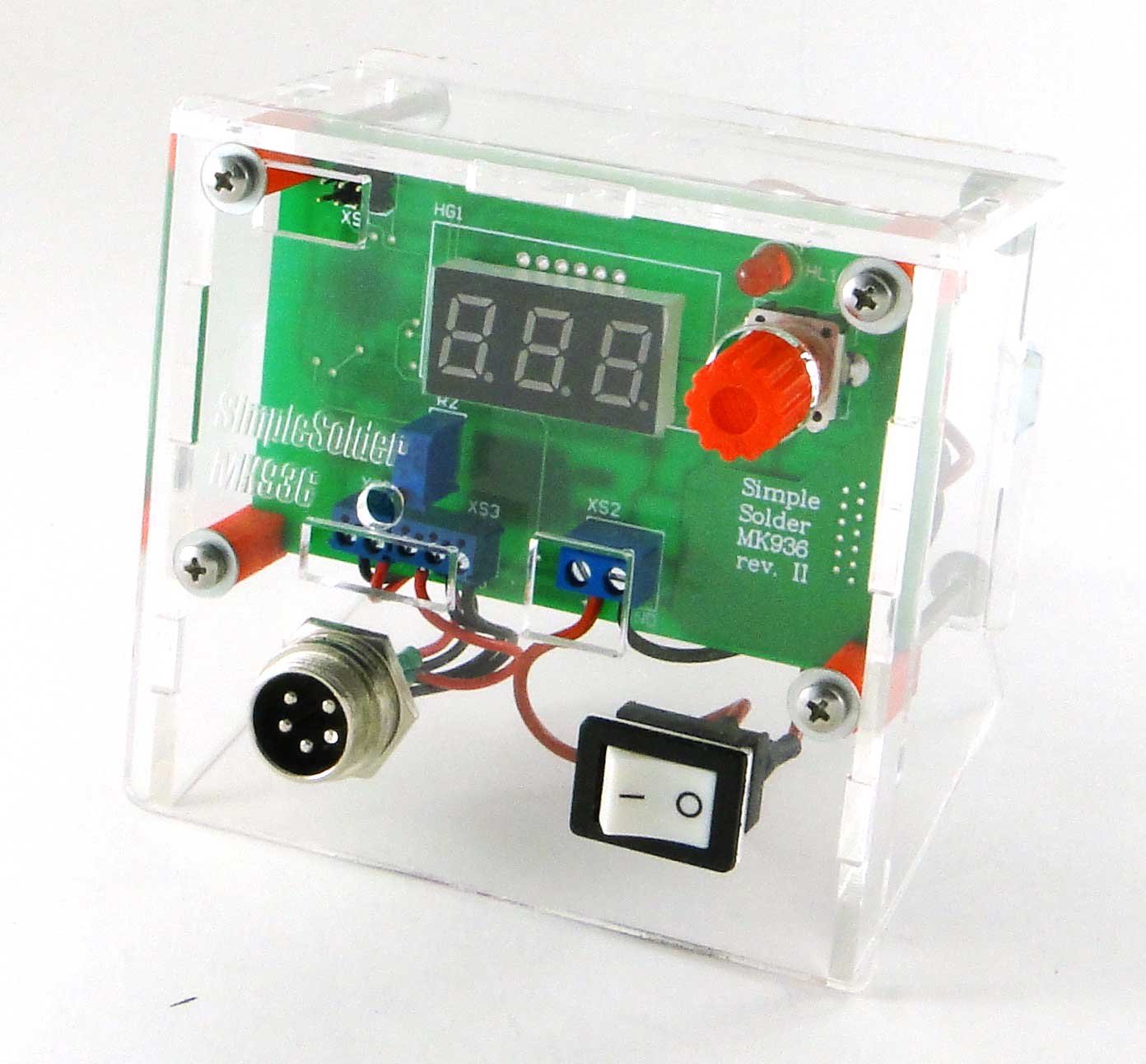

Here is the front side of the PCB assembly:

Assembly of the case and volume installation

The power and soldering iron connection is made as follows:

Before assembling the case, it is necessary to prepare a switch and a connector. The switch must be connected to the break of the red wire so that on one contact of the switch there is a short piece of red thick wire, and on the second a long one.

You need to connect short red wires to the first and fifth pins of the soldering iron connector, and the rest are black.

Heat-shrink tubing should be worn on the switch and the connector and tinned all the free ends of the wires, so that later it was more convenient to screw them into the terminals.

Next, you need to install a switch and a soldering iron connector on the front panel. Please note that the switch can be installed tightly and it may be necessary to modify the slot for it with a file.

Then you should connect the first pin of the connector to the first pin of the board, the second to the second, and so on. in accordance with the above figure. To the power supply on the board, you must connect the red short wire from the switch, and the minus wire is the black wire.

Microcontroller firmware and first start

In the upper left corner of the board there is a standard ISP connector for flashing AVR microcontrollers.

You can flash the microcontroller with any programmer you have, for example USBasp. If the programmer provides power itself supplies 5V, then connect the external is not required. You can also find the firmware file at the end of the article.

Configuration bits! You must enable CKSEL0, CKSEL2, CKSEL3, SUT0, BOOTSZ0, BOOTSZ1 and SPIEN! That is, a change of default settings is required to start the controller at a clock frequency of 2 MHz.

Now you can connect a soldering iron and apply the input supply voltage (from 12 to 24V). After switching on, the soldering iron should begin to heat up, and the temperature reading on the indicator should increase. When the encoder shaft rotates, the value of the required temperature should change.

Completion of assembly

Side walls are installed without any mounts. Now it remains only to insert the back cover into the grooves, tighten the nuts, pull the power wires through the hole and fasten them with cable clamps. Remember that the plexiglass parts are quite fragile and do not overtighten the fasteners!

Calibration

A trimmer is used to fine tune the temperature. The front panel has a special opening for access to it.

When calibrating, first of all it is necessary to bring the sting to the temperature at which the solder melts. You can simply set a very high temperature immediately with the encoder. Then, having collected a solder ball on a sting, it is required to warm up the thermocouple. There are special measuring devices for such purposes, but an ordinary multimeter with a thermocouple will do. Next, by rotating the trimming shaft, ensure that the measured value of the soldering station matches the readings of the external thermocouple.

During calibration, remember that the more time you give the soldering iron to stabilize the temperature, the more accurately you will be able to adjust it. Also note that the trimmer is multi-loop and one revolution changes the temperature very slightly. That is, you need to turn it boldly and a lot.

Video

We also prepared a video instruction:

Links

Direct links to all the necessary files for downloading can be found on the main page of the project .

This device also has a version on a single-sided board using only pin components. You can find it here.

Once again, I want to emphasize that we provide all the necessary and very detailed information for self-fabricating this device, and additionally provide the opportunity to purchase it in the form of a set ( one , two , three ).

PS: and we are also preparing a hairdryer) thanks for your interest in our activities!