Postindustrial or Production 2.0

I was probably too smart with a headline, but oh well.

Having read the articles here and on other resources and seen enough videos about 3D printers, I wanted to do such a thing. So far, having only vague ideas of why I need him, but I realized what I want.

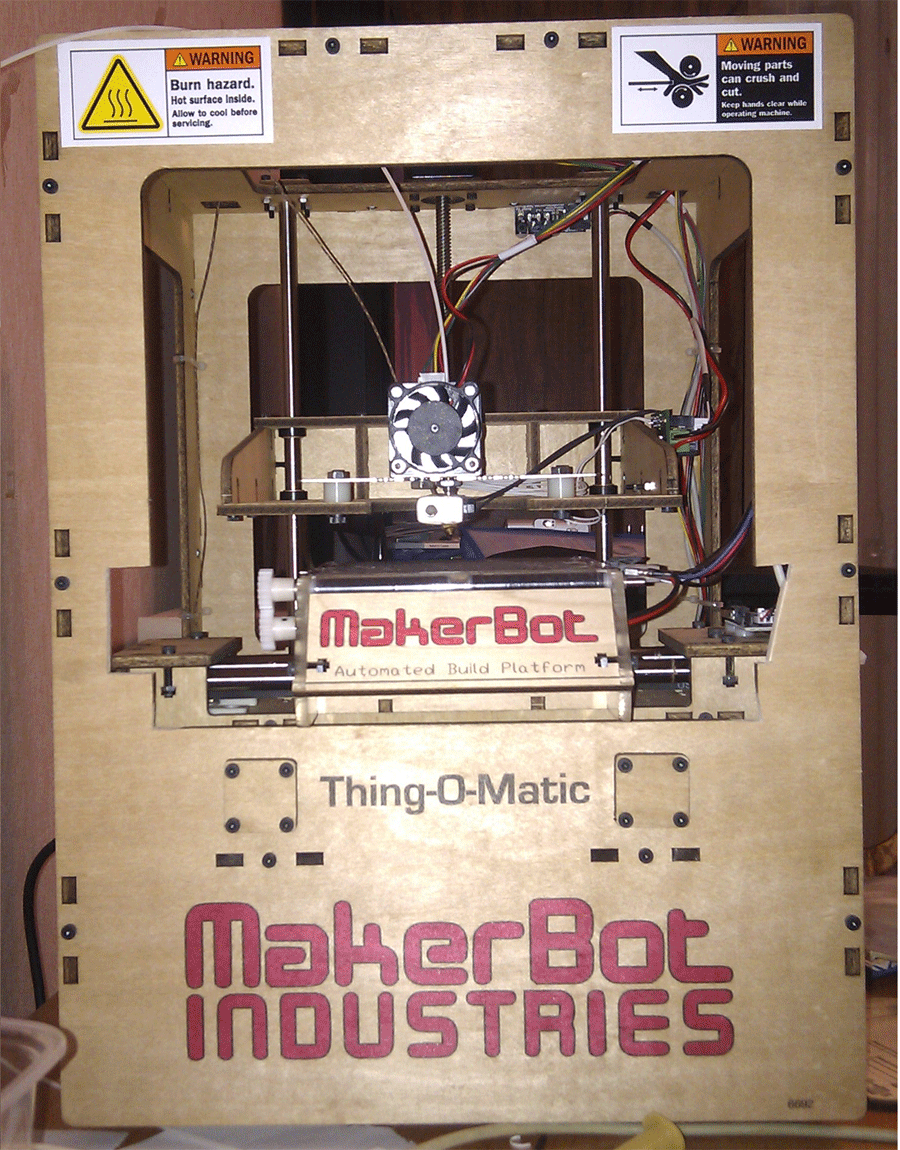

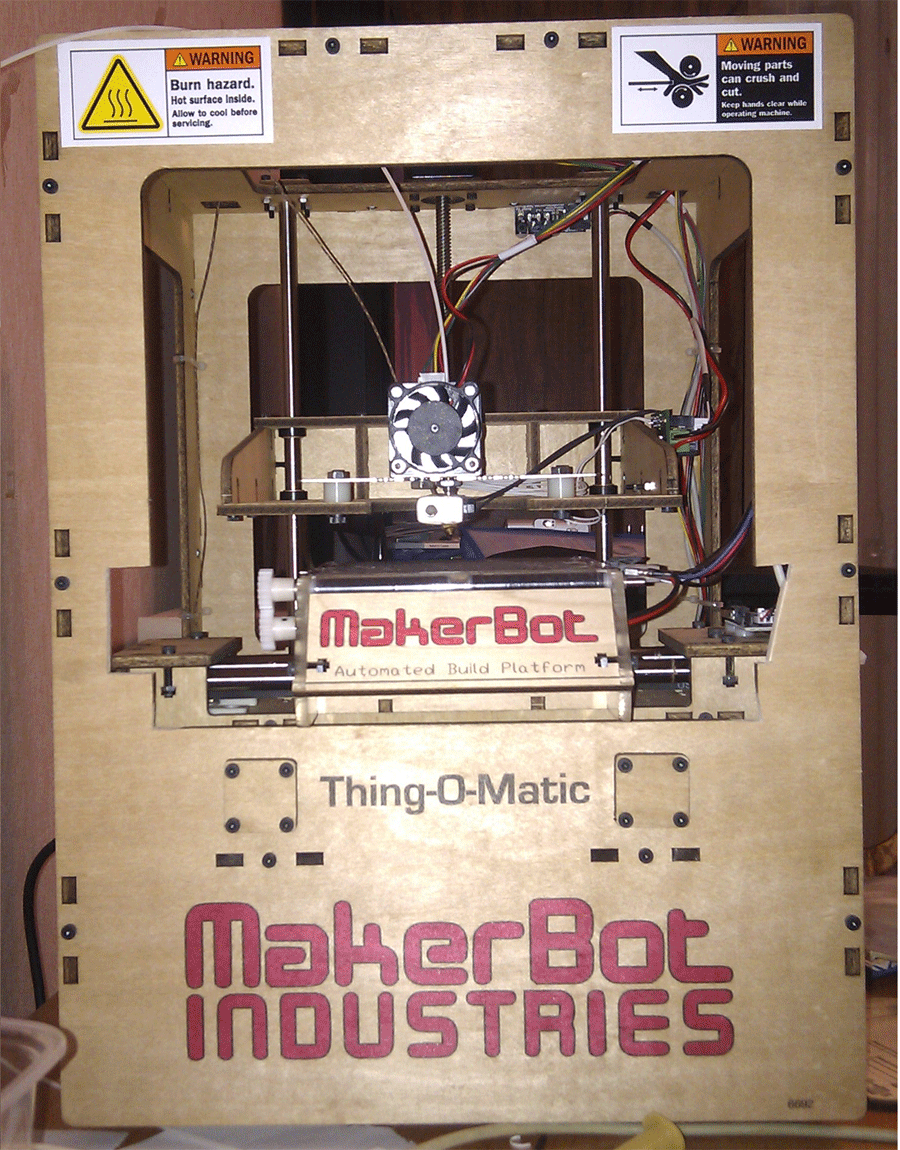

And so, having spent the latter, I bought myself a 3D Printer MakerBot.

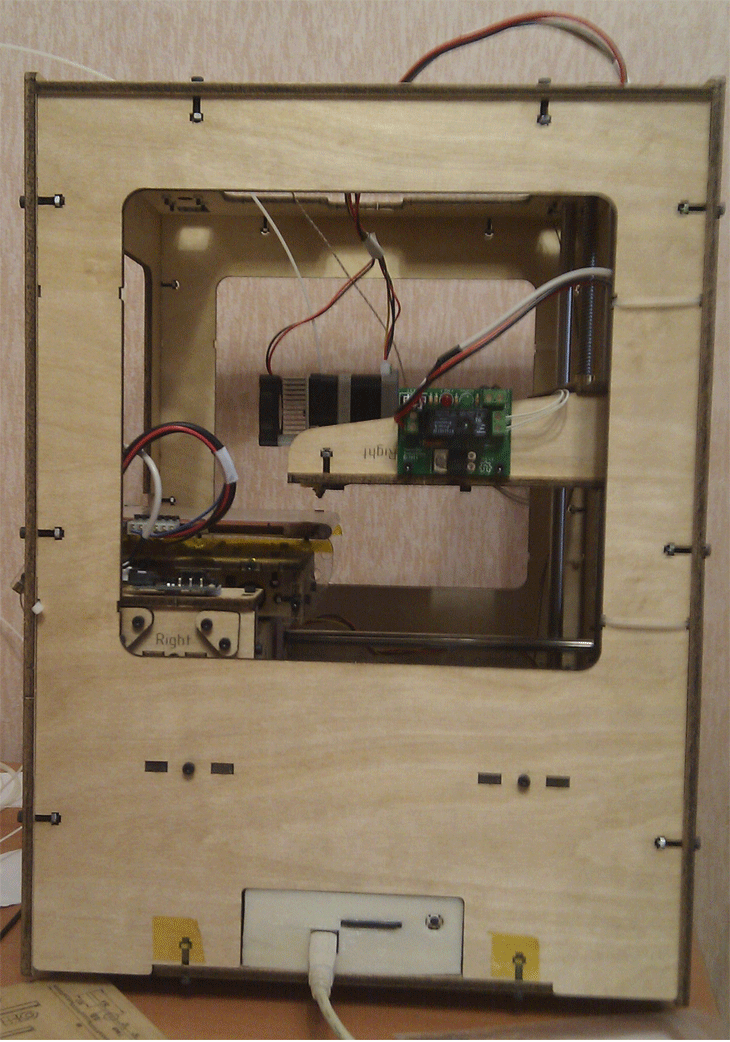

At first, I was very embarrassed that it has a plywood case, although it was made quite accurately.

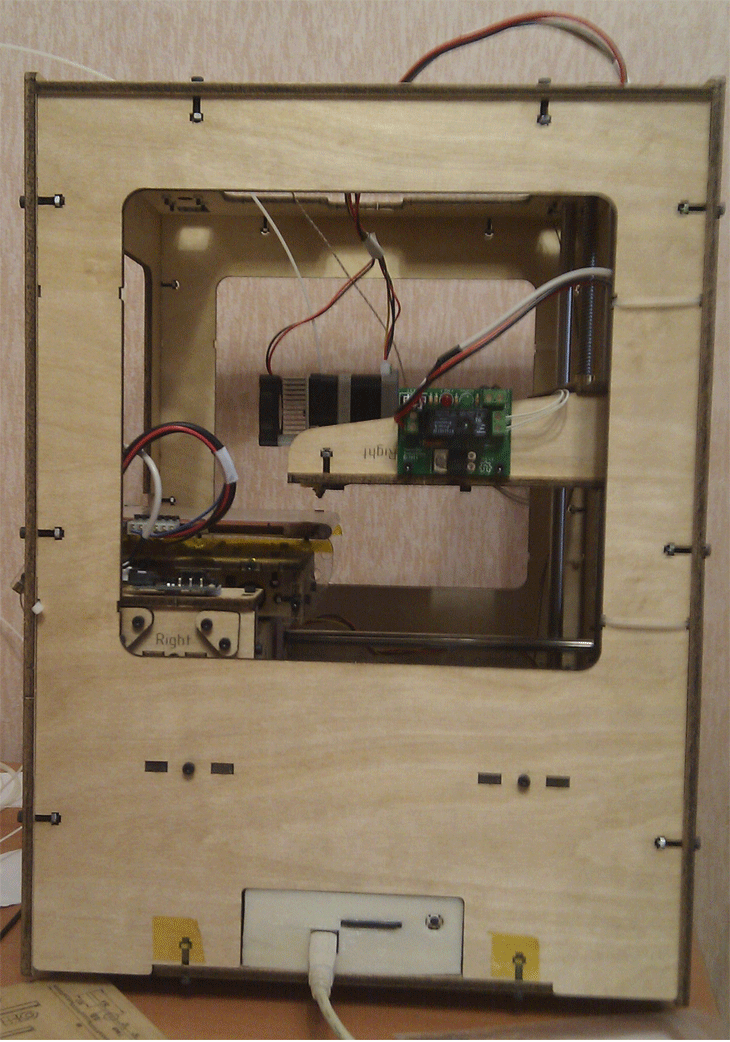

So, I brought it home, unpacked it and put it on the table: I

connected it, installed the drivers for the Arduino 2500, installed the ReplicatorG software, calibrated it (done once when connecting to the new Replicator installation), inserted a plastic thread and tried to print it - the first time it didn’t work: -).

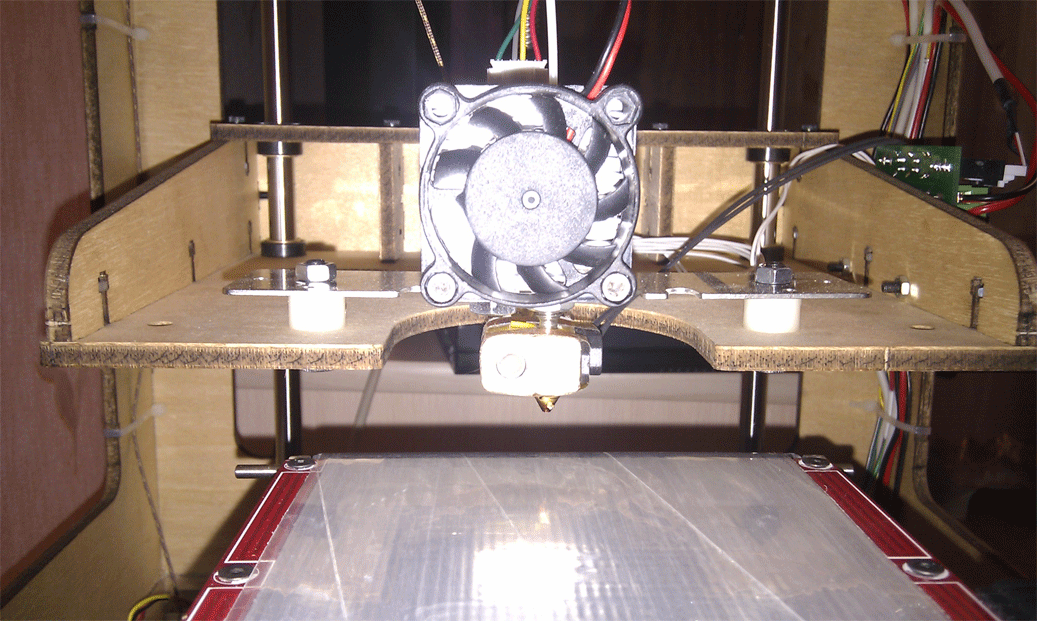

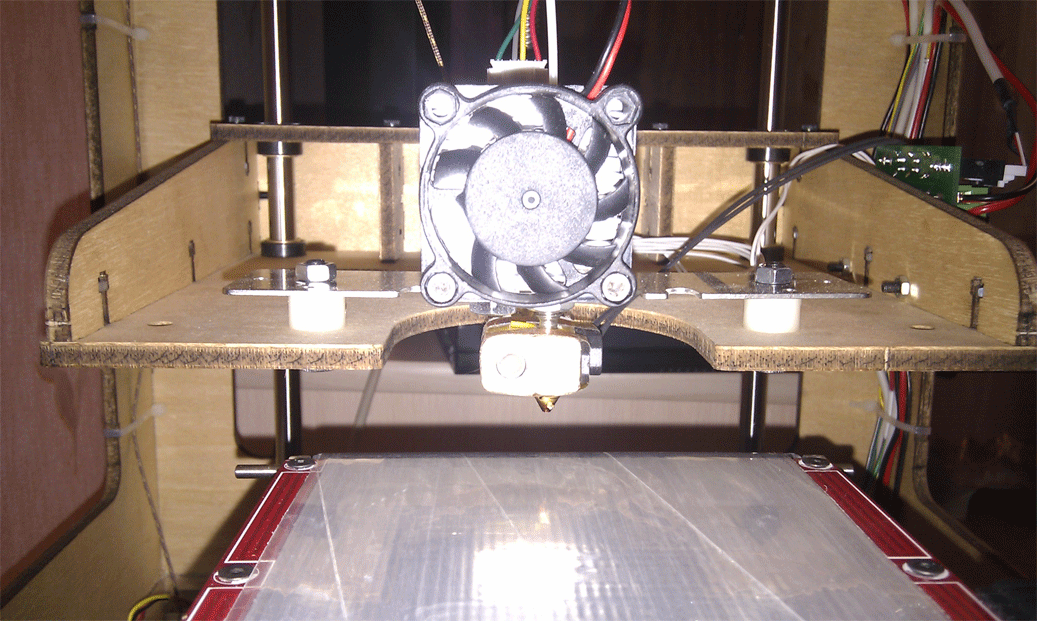

In the settings, the insufficient melting temperature of the plastic was set. Actually, the “print" head and platform itself:

The diameter of the print nozzle is 0.4 mm.

Printing dimensions - 100x100x100 mm.

The head moves along the Z axis, the platform moves along X and Y, respectively.

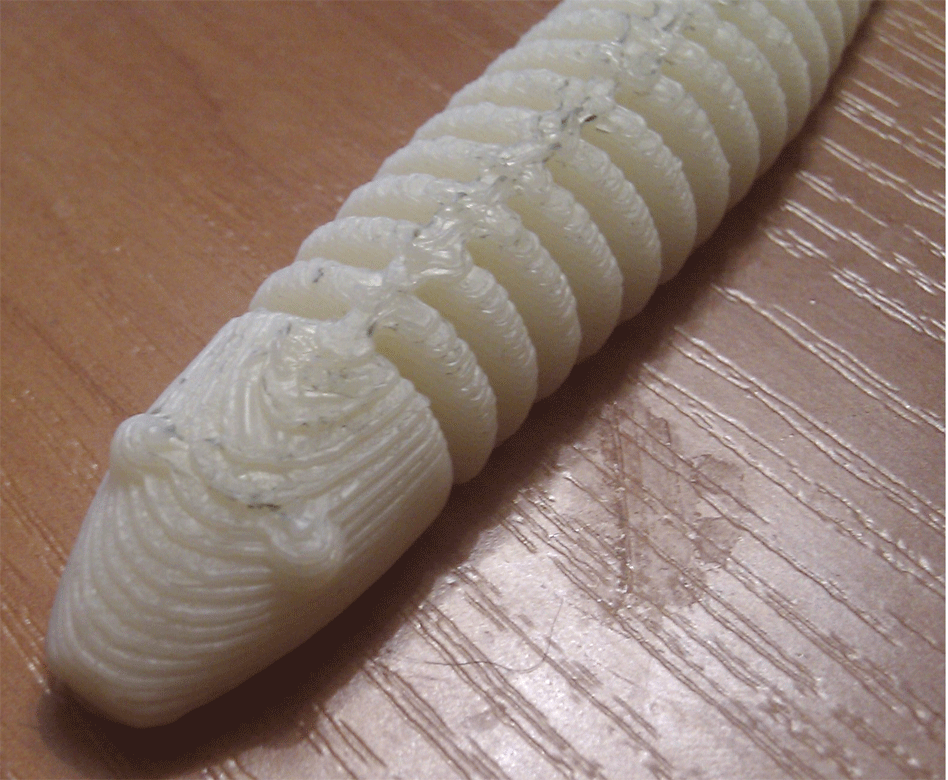

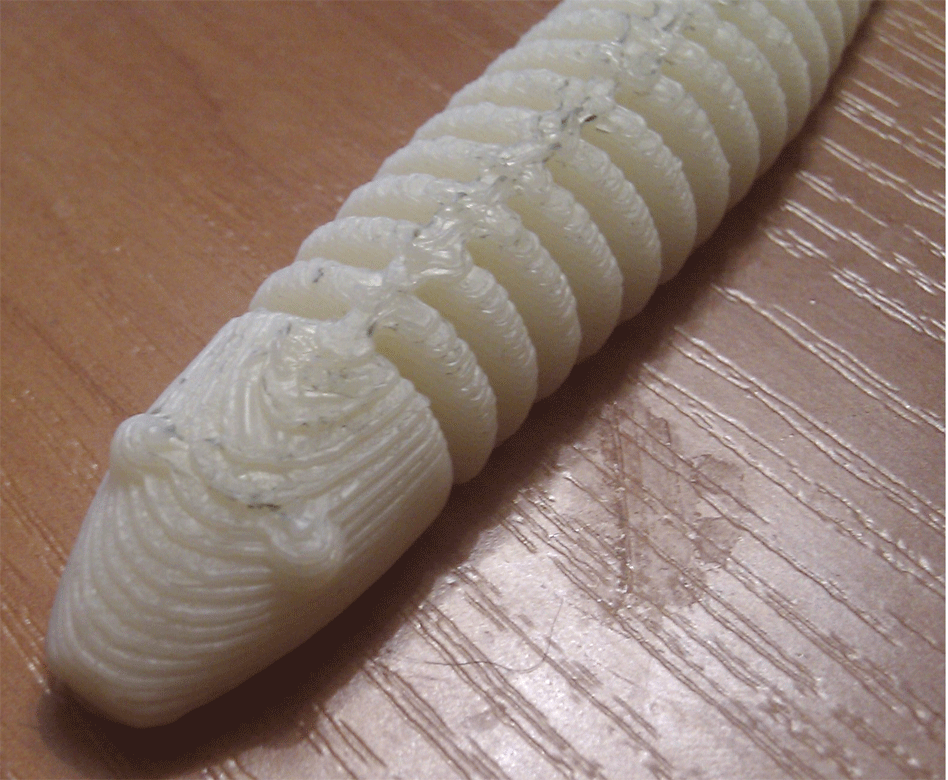

Having dealt with the settings, the first part that I printed was like this:

Larger so that the layers were visible:

In fact, I screwed up the layer thickness, here I set the layer to 2 times thicker than recommended, so the details are more accurate.

For a nozzle of 0.4 mm, the recommended layer thickness is 0.29 mm, for comparison, in the previous picture, the layer thickness was set to 0.5.

First impressions are positive, I would even say enthusiastic. Now I can print whatever I want. Speaking of creating parts, I printed a part created in KOMPAS 3D (it can save in .stl format, which understands the software used for the printer).

There are some inconveniences, for example, when applying the first layer, plastic does not always adhere to the platform (especially some small parts), because of which the part may not work, though it is “treated” by printing the substrate. Although the substrate has its own difficulties, it is not always easy to separate from the part itself.

For protruding parts, you can put the option of printing support, that is, the "extra" in terms of detail components that will allow printing "on weight".

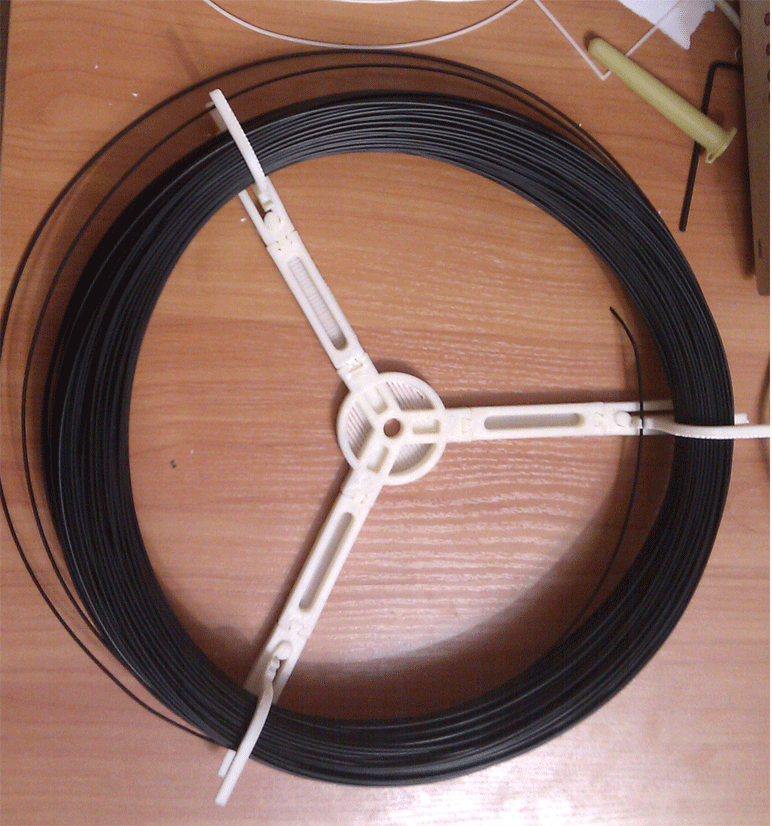

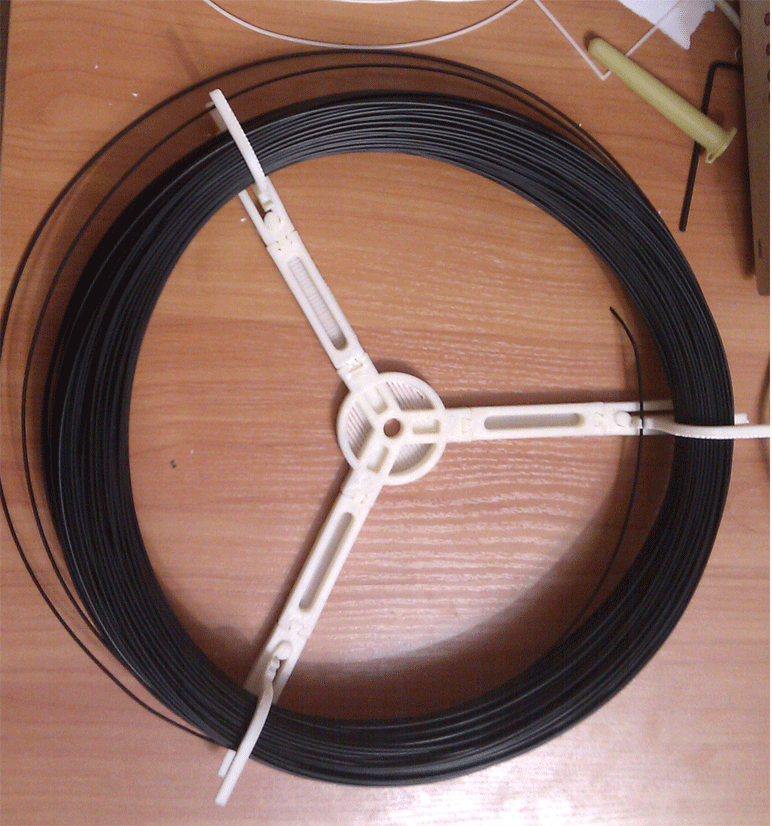

This is what consumables look like:

A kilogram of such a thread costs from $ 50 to $ 100. 50 grams took to the “snake”, the pictures of which were given above. The

plastic is dissolved in acetone and this mixture can be used to process printed parts to smooth out irregularities on the surface.

It is also necessary to periodically wipe the print head with acetone.

I was very pleased with the ability to print parts and additional components for this printer on this printer, for example, a holder for plastic thread:

A lot of examples for printing can be found here: http://thingiverse.com/

In my opinion, for printing you need to have some knack, which acquired with experience.

It is also necessary to periodically check the fasteners - tighten the screws, since during printing they are slightly untwisted.

In conclusion, I want to say that I am very pleased with the acquisition, and it is very mesmerizing when you look at the “growing” part.

PS The article turned out to be somewhat messy, but I did not want to describe how the printer works, this is already described in many places. I tried to describe my thoughts and feelings, I hope that it turned out.

Having read the articles here and on other resources and seen enough videos about 3D printers, I wanted to do such a thing. So far, having only vague ideas of why I need him, but I realized what I want.

And so, having spent the latter, I bought myself a 3D Printer MakerBot.

At first, I was very embarrassed that it has a plywood case, although it was made quite accurately.

So, I brought it home, unpacked it and put it on the table: I

connected it, installed the drivers for the Arduino 2500, installed the ReplicatorG software, calibrated it (done once when connecting to the new Replicator installation), inserted a plastic thread and tried to print it - the first time it didn’t work: -).

In the settings, the insufficient melting temperature of the plastic was set. Actually, the “print" head and platform itself:

The diameter of the print nozzle is 0.4 mm.

Printing dimensions - 100x100x100 mm.

The head moves along the Z axis, the platform moves along X and Y, respectively.

Having dealt with the settings, the first part that I printed was like this:

Larger so that the layers were visible:

In fact, I screwed up the layer thickness, here I set the layer to 2 times thicker than recommended, so the details are more accurate.

For a nozzle of 0.4 mm, the recommended layer thickness is 0.29 mm, for comparison, in the previous picture, the layer thickness was set to 0.5.

First impressions are positive, I would even say enthusiastic. Now I can print whatever I want. Speaking of creating parts, I printed a part created in KOMPAS 3D (it can save in .stl format, which understands the software used for the printer).

There are some inconveniences, for example, when applying the first layer, plastic does not always adhere to the platform (especially some small parts), because of which the part may not work, though it is “treated” by printing the substrate. Although the substrate has its own difficulties, it is not always easy to separate from the part itself.

For protruding parts, you can put the option of printing support, that is, the "extra" in terms of detail components that will allow printing "on weight".

This is what consumables look like:

A kilogram of such a thread costs from $ 50 to $ 100. 50 grams took to the “snake”, the pictures of which were given above. The

plastic is dissolved in acetone and this mixture can be used to process printed parts to smooth out irregularities on the surface.

It is also necessary to periodically wipe the print head with acetone.

I was very pleased with the ability to print parts and additional components for this printer on this printer, for example, a holder for plastic thread:

A lot of examples for printing can be found here: http://thingiverse.com/

In my opinion, for printing you need to have some knack, which acquired with experience.

It is also necessary to periodically check the fasteners - tighten the screws, since during printing they are slightly untwisted.

In conclusion, I want to say that I am very pleased with the acquisition, and it is very mesmerizing when you look at the “growing” part.

PS The article turned out to be somewhat messy, but I did not want to describe how the printer works, this is already described in many places. I tried to describe my thoughts and feelings, I hope that it turned out.