Fundamentals of semiconductor manufacturing economics

Once upon a time - at the beginning of the century - I bought a regular mobile phone, the cheapest one, it cost about 15 or 20 euros. And to him the cover. Which also cost about 15-20 euros. This fact struck me - a phone in which a semiconductor chip stands, which is the pinnacle of human technology, which requires billions of dollars worth of equipment, highly qualified specialists who studied at universities and defended dissertations, the results of scientific research of thousands of scientists - and all this costs the same , how much is a regular case, the production technology of which has not changed much in the last few thousand years. How so? Let's try to understand.

Introduction

At once I will make a reservation that the figures given in the article are not an exact calculation of the cost of a particular product. Nevertheless, the figures are not taken from the ceiling, but from the experience of working at a large semiconductor factory (GlobalFoundries, a former AMD factory) and the management of a small MEMS- factory. Thus, we will consider a spherical semiconductor factory in a vacuum, which, on the one hand, is not a real copy, on the other hand, helps to understand the trends in the formation of the cost of semiconductor products. I also want to emphasize that we will talk about the cost of semiconductor products. The price will be determined by other factors:

What is the cost of semiconductor products?

Let's compare the cost of production at a factory with a different size of plates (with a diameter of 100 mm to 300 mm), different production load and different usable yield. To do this, we will need to understand what expenses are necessary for production, how they depend on production volumes, how many chips will fit on plates of different sizes and what will be the scrap rate (the reverse side of the yield).

Let our factory produce CMOS logic, with a maximum output of 600,000 plates per year. We spent $ 1 billion on equipment.

Costs

Production costs are divided into two types - fixed, which do not depend on the volume of production and direct (variable) - which directly depend on the volume of production. In addition, some (indirect) costs will increase with the volume of production, but not in proportion to it.

Direct costs

- Silicon wafers. The most obvious component of a semiconductor chip, but its contribution to cost is rather small. A 100 mm plate costs about $ 30- $ 40, 300 mm - $ 70- $ 80. As we will see later, the plate contributes to the cost of about 1%. We will not consider cases of use of SOI plates (their cost is much more).

- Chemicals and gases. In modern technical process contains about 300 steps. Some of them require expensive chemicals (for example, a resist for lithography or a target for metal sputtering), some do not require chemicals at all (for example, metrology) or they are very cheap (for example, oxidation of silicon in oxygen). It is rather difficult to calculate the exact amount of chemicals and their cost for each operation, but if you just take the total cost of chemicals and divide by the number of operations and plates, the calculations are greatly simplified. In this case, one operation on one plate will take about $ 10 chemicals. Thus, if we have 300 operations in the technical process, then we will spend $ 3000 to make one plate.

- Masks (photomasks). If we produce a lot of products and constantly change them, the cost of photo patterns will be significant. If we produce one product, then the cost of photomasks will not depend on the volume of production. For ease of analysis, suppose we produce only one product and include the cost of making photo masks in fixed costs.

Indirect expenses

- Electricity.At first glance, these are direct costs, but in reality electricity consumption is not directly proportional to the volume of production. The fact is that semiconductor equipment is constantly on, even if it is idle. This is done because it may take quite a long time to get into operation. For example, in vacuum equipment, widely used in semiconductor manufacturing, most of the electricity is consumed by pumps that are constantly running; the ovens maintain the working temperature, water cooling, ventilation and air conditioning systems in clean rooms, etc. work. Thus, with an increase in production volumes, the consumption of electricity will increase insignificantly and since its share in the cost is not so large, in the first approximation we can assume that these are fixed costs,

- Payroll. As production increases, you may need more employees, but the link is not directly proportional. Firstly, the number of administrative workers will remain almost unchanged. Secondly, the number of engineers may increase, but only slightly. When the factory works 24/7, engineers work 8/5 and only some attendants cover the weekend. With an increase in the number of shifts, the number of operators will increase proportionally, but, firstly, with a high degree of automation of production, many operators are not needed, and secondly, this is a relatively low-paid category of employees. Thus, with the introduction of 4 shifts in production instead of one, labor costs will increase by 20 to 30 percent.

- Equipment maintenance and repair. They make up about 5% of the cost of equipment per year. A lot of regular maintenance works, which sometimes depend, sometimes do not depend on the volume of production. The total cost is not directly proportional to the volume of production.

Fixed costs

This includes everything else that does not depend on the volume of production - depreciation of equipment, rent of land, repair of buildings, maintenance of the office, etc. etc. Separately, focus on depreciation. Path equipment is depreciated over 5 years. Then, with a total equipment cost of $ 1 billion, we must include $ 200 million a year in expenses.

Putting it all together, we will see that our fixed costs are approximately $ 1.5 billion per year and let them grow by 10% with the introduction of one additional shift. Thus, the cost of one plate will be the sum of the direct costs of producing one plate + fixed costs for the whole factory divided by the number of plates = $ 3,100 + $ 1.5 billion / volume of production. We make the first calculations:

| Number of shifts | Production capacity, plates per year | Fixed costs, billion $ | Plate cost, $ |

|---|---|---|---|

| one | 150,000 | 1.5 | 13,100 |

| 2 | 300,000 | 1.65 | 8,600 |

| 3 | 450,000 | 1.82 | 7,130 |

| four | 600,000 | 1.99 | 6,425 |

The first conclusion that we can do: it is advantageous for us to load our factory to the maximum - this significantly reduces the cost price of one plate (twice when switching from one shift to four). Now let's talk about chips - after all, the cost of the chip, and not the entire semiconductor wafer, is important for the end user.

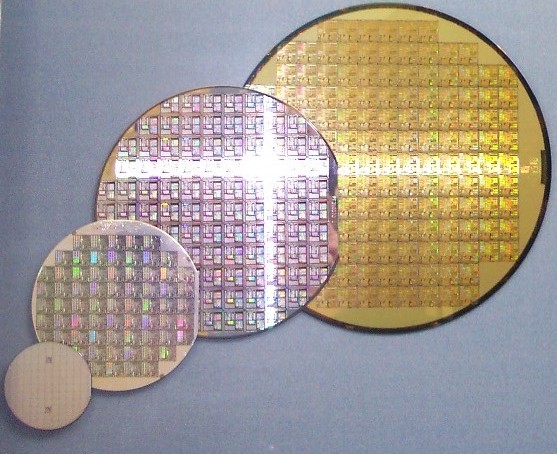

Plate size

Semiconductor wafers from 51 mm to 200 mm. Source: Wikipedia, By German Wikipediabiatch, original upload 7. Okt 2004 by Stahlkocher de: Bild: Wafer 2 Zoll bis 8 Zoll.jpg , CC BY-SA 3.0 , Link

To find out how many chips will be on the plate you need to know the chip size and size plates. There is a handy calculator on the Internet that allows you to quickly estimate how many chips will fit on plates of different sizes. For example, let's take chips of different sizes, “large” Intel Sandy Bridge E 6C (435 mm2) and “small” Qualcomm Snapdragon 835 (72.3 mm2) and see how many of them fit on plates of different sizes.Disclaimer: the chips are taken just for example sizes, the subsequent calculation of the cost has nothing to do with the actual cost of these products. In addition, it is clear that the same chip cannot be made on a 100 mm and 300 mm plate, but we are considering a spherical factory in a vacuum, so let's just count.

| Plate size, mm | Number of chips 435 mm 2 | Number of chips 72.3 mm 2 |

|---|---|---|

| 100 | 9 | 69 |

| 150 | 24 | 180 |

| 200 | 52 | 345 |

| 300 | 127 | 836 |

Given that the cost of manufacturing one plate is almost the same, from this table we make two very important conclusions:

- The smaller the chip, the more they are on one plate, the cheaper it is . Therefore, by reducing the size of transistors, we can either reduce the cost with the same functionality (without changing the number of transistors the chip will be less), or by increasing the number of transistors without changing the chip size we will get an increase in performance / functionality at the same cost (same chip size). It becomes clear race for reducing the size of transistors ( Moore's law ): either cheaper or higher performance at the same cost.

- The larger the plate, the cheaper one chip. It should be noted that the equipment for plate sizes from 100 mm to 200 mm is practically the same, so the cost of processing one plate of 100 mm, 150 mm and 200 mm will be the same. For 300 mm equipment is more expensive, so we have to increase fixed costs (depreciation and maintenance) for subsequent calculations. We accept this increase equal to 50% of the cost of fixed costs.

Yield

An example of a card of an exit of suitable chips of a plate. Red marked defective chips. Source: DOI: 10.1155 / 2015/707358

He likes to repeat the leadership of semiconductor factories. We have three major goals: yield, yield and yield (We have three main goals - the yield, the yield, and the yield). The yield of the cost affects the cost directly - the more the yield on the plate, the cheaper the chip, since the cost of the plate does not change (from an economic point of view, an increase in marriage is equivalent to a decrease in the size of the plate). At first glance, the concept of yield is quite simple - we just consider the percentage of working chips, but there are some nuances.

If the chip is simple, for example, the wireless module of the phone, then it either works or not, everything is simple. If the chip is complex, for example, it has several cores and a graphics co-processor on a single chip, then everything is a little trickier. If you are lucky, then everything works. If not, then, for example, only two of the four cores work. Or the graphic coprocessor does not work. What to do in this case? It's very simple - we make a product line: a quad-core processor with graphics, a dual-core processor with graphics, a dual-core processor without graphics, etc. In addition, they can operate at different frequencies (well, this was due to the variation in the size of the devices on the plate). That is, if you see a line of processors, it does not mean that there are several technical processes and photomasks. Most likely tehprotsess one

Another aspect is as follows: the yield of suitable falls mainly due to defects, which have a certain probability of occurrence per unit area of a semiconductor wafer. Obviously, a larger chip is more likely to catch a defect and fail more than a smaller chip. Thus, the yield of small chips will be greater than the yield of large chips with the same number of defects on the plate.

Cost calculation

So, we found out that we have several main factors affecting the cost of the chip:

- Volume of production

- Plate size

- Chip size

- Yield

It is rather difficult to build a pivot 4-D table, so let's consider several examples: The

chip cost ($) of 72.3 mm2 in size with a yield of 80% for a factory operating with different loads and different plate sizes:

| Number of shifts | 100 mm | 150 mm | 200 mm | 300 mm |

|---|---|---|---|---|

| one | 237 | 90 | 47 | 27 |

| 2 | 155 | 59 | 41 | sixteen |

| 3 | 129 | 49 | 36 | 13 |

| four | 146 | 44 | 33 | 12 |

Going from 100 mm plates to 300 mm and from one shift to four, we reduced the cost price of the chip by 20 times!

The cost of chips (in $) of different sizes depending on the yield on the 300 mm plate with a full factory load:

| Yield | Chip 435 mm 2 | Chip 72.3 mm 2 |

|---|---|---|

| 60% | 106 | sixteen |

| 70% | 91 | 14 |

| 80% | 79 | 12 |

| 90% | 71 | ten |

| 100% | 64 | 9 |

Well, we got the answer to the original question - how a mobile phone can cost several tens of dollars despite the fact that there are high-tech products there. We began with billions of dollars in investments and billions of budgets and came to the conclusion that the cost of one small chip (it is unlikely that it is very large in a simple push-button telephone) produced in a fully loaded factory running on 300 mm plates is measured in units of dollars.

Now, just out of curiosity, let's see what happens if we want to organize the production of chips in Russia.

Production of chips for the Russian market

Disclaimer: all numbers and names are made up, any coincidences are random.

Suppose we organized a certain company “Nanometr” and want to produce a certain processor “Sayany” with a size of 256 mm2. To do this, we purchased equipment for about $ 1 billion, which works on 200 mm plates and is capable of producing 600,000 plates per year. On one plate we get 91 chips and let us achieve a yield of 70%, that is, we will get 63 chips from one plate. Using the above calculations, we estimate the cost of production of such chips:

| Shifts | Number of chips | Cost, $ |

|---|---|---|

| one | 9 450 000 | 207 |

| 2 | 18,900,000 | 136 |

| 3 | 28 350 000 | 113 |

| four | 37 800 000 | 102 |

That is, the total cost of all the chips produced will be $ 3.5-3.8 billion. The main question is whether there is a market in Russia for selling tens of millions of processors (or any other chips)? The global semiconductor market amounted to about $ 463 billion in 2016 , the Russian market, according to various estimates, ranges from 0.3 to 1% of the world, i.e. somewhere $ 2-4 billion, which is approximately equal to the cost of all our products, but we also want profit, and in the market we are not alone. It turns out that if we want to produce chips for the domestic market, we need to either enter global markets (and sell a substantial share of our products there), or not fully load the factory with a corresponding increase in cost (well, and prices for the final consumer).

Conclusion

Even if you have invested billions of dollars in the equipment and operation of a semiconductor plant, you can produce quite complex chips, the cost of which will be tens of dollars (and for small units). To do this, you need to completely load your factory (work 24/7), use 300 mm wafers, try to make the chip as small as possible and achieve high yield. And do not forget to find those to whom you are going to sell these chips - otherwise they will not be cheap.