Why are rockets fairing so expensive?

This article is based on the following comments and requests:

Hunting for fairings

At the moment, the price of fairings for missiles is about 5-7 million dollars. Many wonder: Why is it so expensive? It's just a piece of metal to protect. This is not entirely true; it is not just a piece of metal, although this design was made to protect the payload.

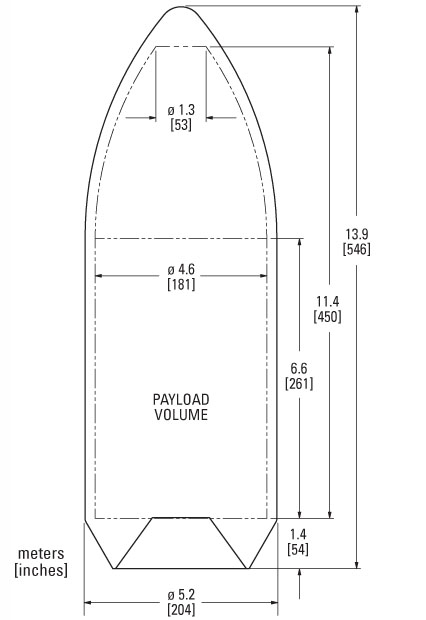

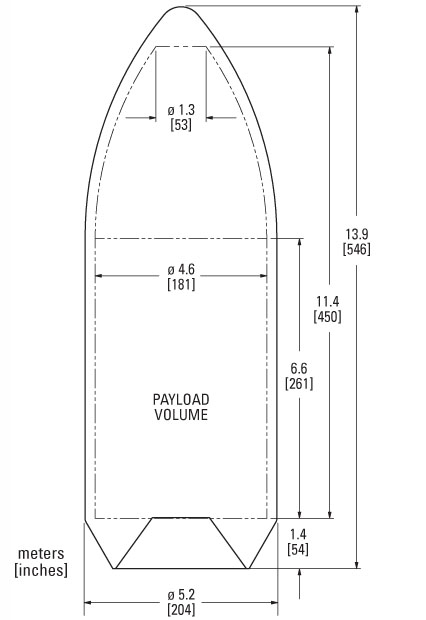

Let's start small. Each kilogram of fairing reduces the weight of the payload. Therefore, light composites with a reinforced structure with light alloys are used, usually aluminum alloys. The design resembles a honeycomb (isogrid). The weight of the Falcon 9 fairing with a diameter of 5.2 meters is about 1.9 tons.

By the choice of material also fit with special care, because the fairing should protect from the oncoming air flow, from EMI radiation, from temperature changes, from other vibrations and mechanical effects on MO. For example, the Falcon Heavy passes the sound barrier at an altitude of about 10 km, and then accelerates to 7-8 sweeps (2-3km / s). At these altitudes, the air is still quite dense and there is a strong warming up of the fairing with rapid cooling in the upper layers of the atmosphere. Temperature fluctuations can be from 100C to -100C in a short period of time (about a minute). Therefore, the material must be resistant to rapid temperature changes.

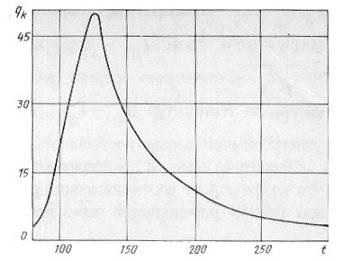

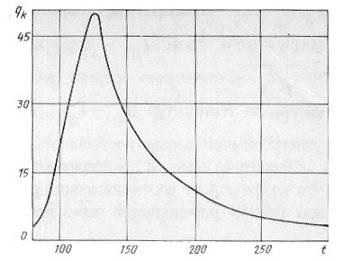

Using the example of the head fairing of a rocket, we consider the effect of aerodynamic heating on it. The figure shows the change in the convective heat flow in the nose of the fairing that occurs when braking the gas flow near the streamlined surface.

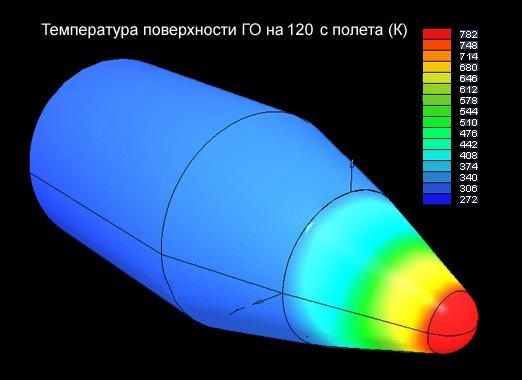

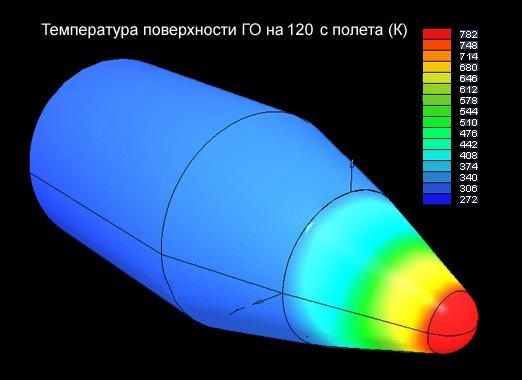

This heat flux causes heating of the surface of the head fairing (GO). The temperature distribution over the HE surface is shown in the following figure.

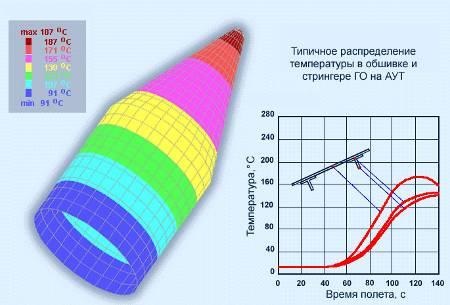

As can be seen from the figure, the temperature of the nose of the HE exceeds the permissible operating value for aluminum alloys. Therefore, an HRC made of asboplastic or fiberglass on a phenolic binder is applied to the outer surface of the nose of GO:

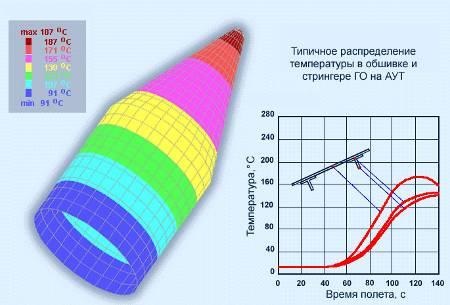

The temperature distribution of the structure of the HO having the HRC of the nose is shown in the figure:

It can be seen from the figure that both in the casing and in the longitudinal power set (stringers) the working temperature during the flight is within acceptable limits. However, for a spacecraft inside the GO, the heat flux from the design of the fairing may be unacceptable, as a result of which thermal insulation of the heated structure from the inner cavity of the GO is necessary.

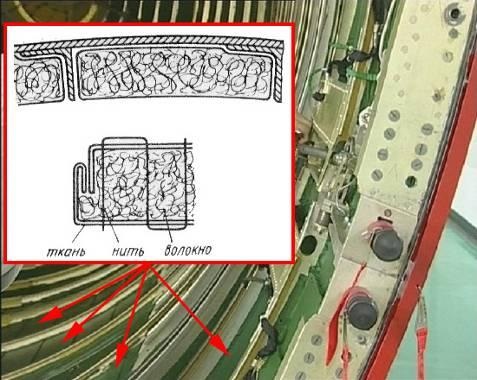

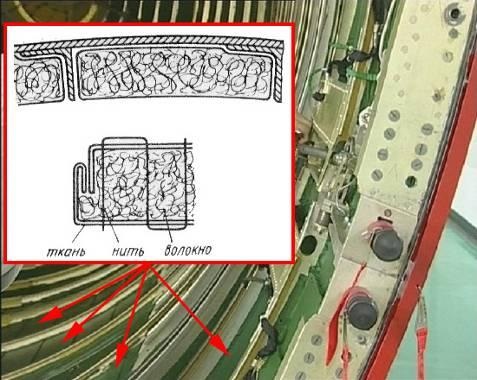

The device of such thermal insulation (TI) is shown in the figure:

It is necessary to maintain the temperature 10-30С for the spacecraft under the fairing.

Also, the fairings should be able to ventilate so that, in the process of going out into space, the pressure inside the compartment must be equalized so that the fairing does not destroy the inside of ahead of time.

Another complication is that the fairings should be opened ideally so as not to damage the Mon and missile stages below them at a speed of about 3-4 km / s. That is, there must be a special mechanism for separating the fairings from Mon, without damaging the payload and the stage below it. A good video test of the Space X fairings in a vacuum chamber at the Glenn Research Institute, NASA:

For the opening of the fairing and for the separation of the steps as a whole, there is a separation system.

The separation system (CP) is designed for separation and removal from the trajectory of the removal of the exhaust stages, as well as for the garbage of structural elements that have fulfilled their functional purpose. Structural elements of the SR to act must ensure the integrity of the design of the PH and the perception of all loads. The operation of the CP elements is carried out very quickly, as a result of which sources of rapidly released energy (explosive, pressure accumulators, springs, etc.) are on board. After the operation of discontinuous elements, a complex dynamics of relative

motion occurs . The structure of the CP includes units, components and mechanisms that provide:

- reliable connection of separable parts and breaking of force bonds,

- dilution of separable parts.

The first group includes pyrozamki, pyrobolts pnevmozamki, mechanical locks, shell elements with linear detonating charges. Breeding is provided by pushers (pneumatic, pyro, spring), nozzles for pressurized gas, brake solid propellants, engine thrust.

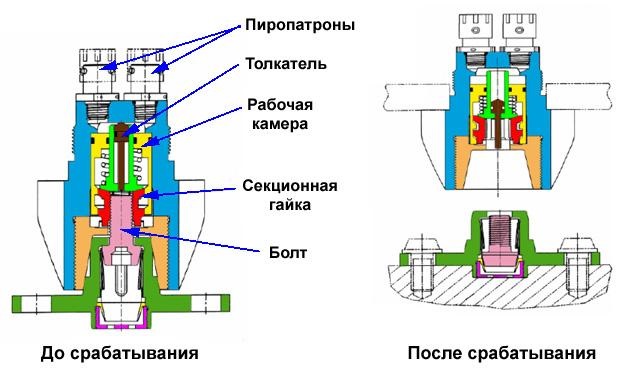

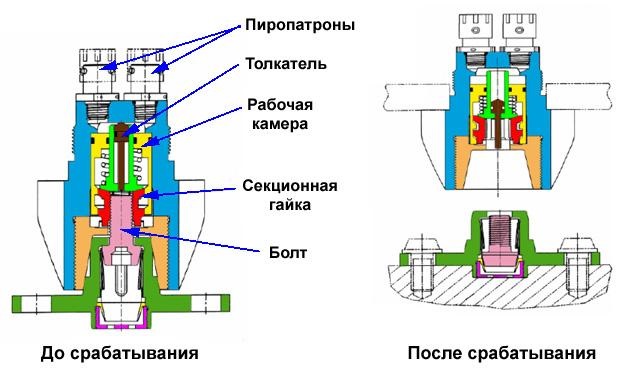

Separation system pyrobolt:

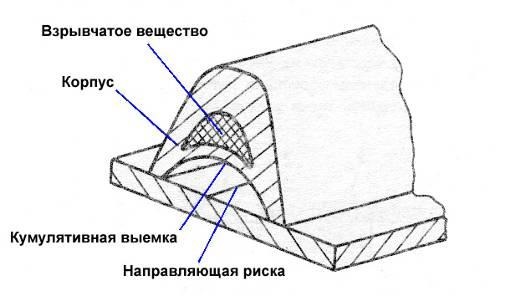

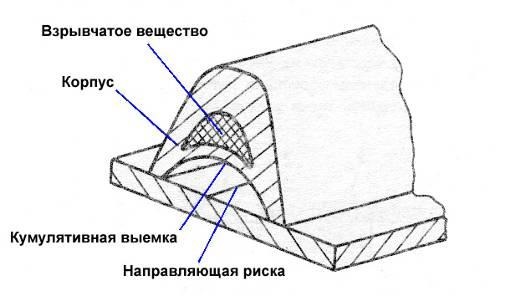

Linear detonating projectile:

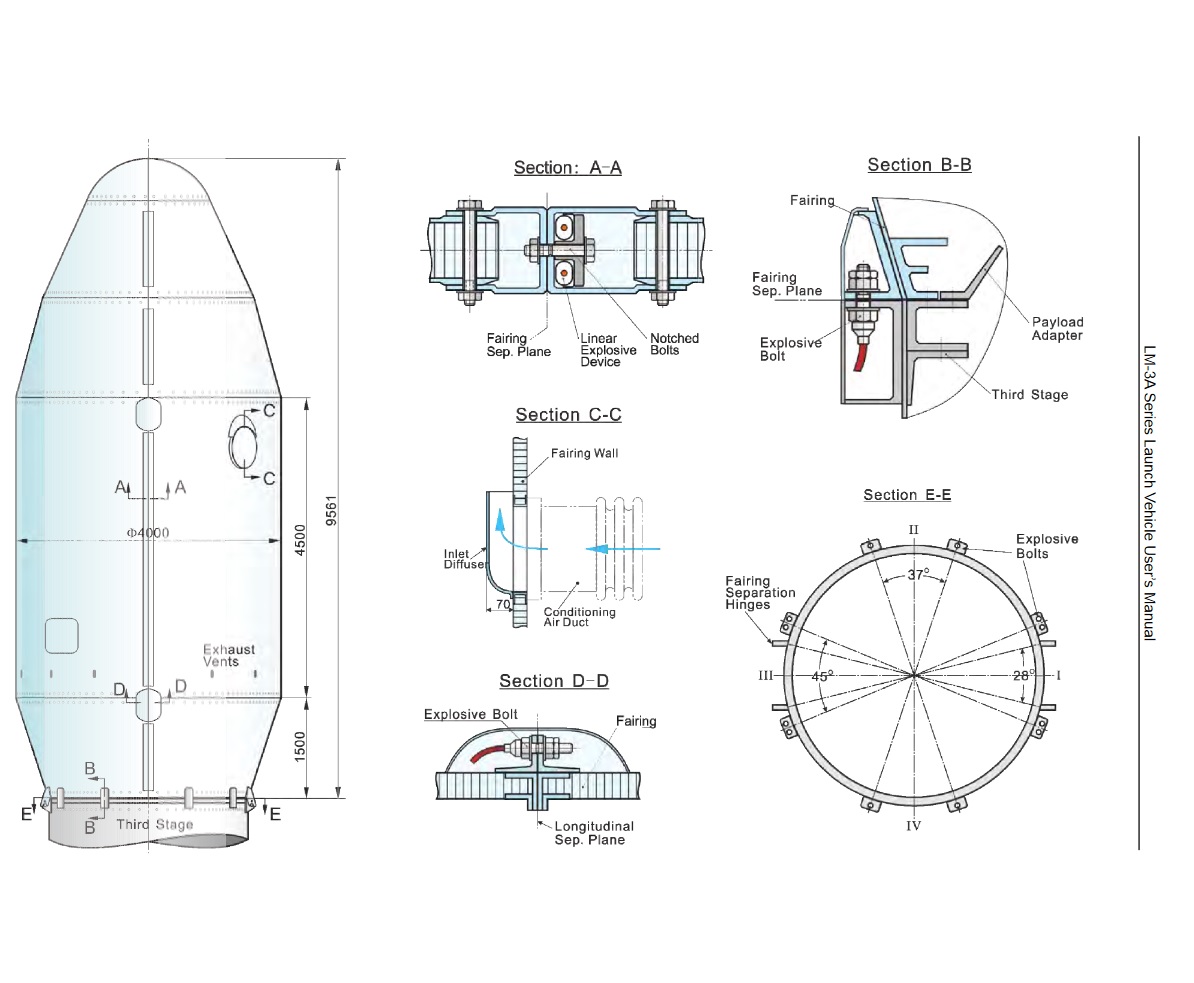

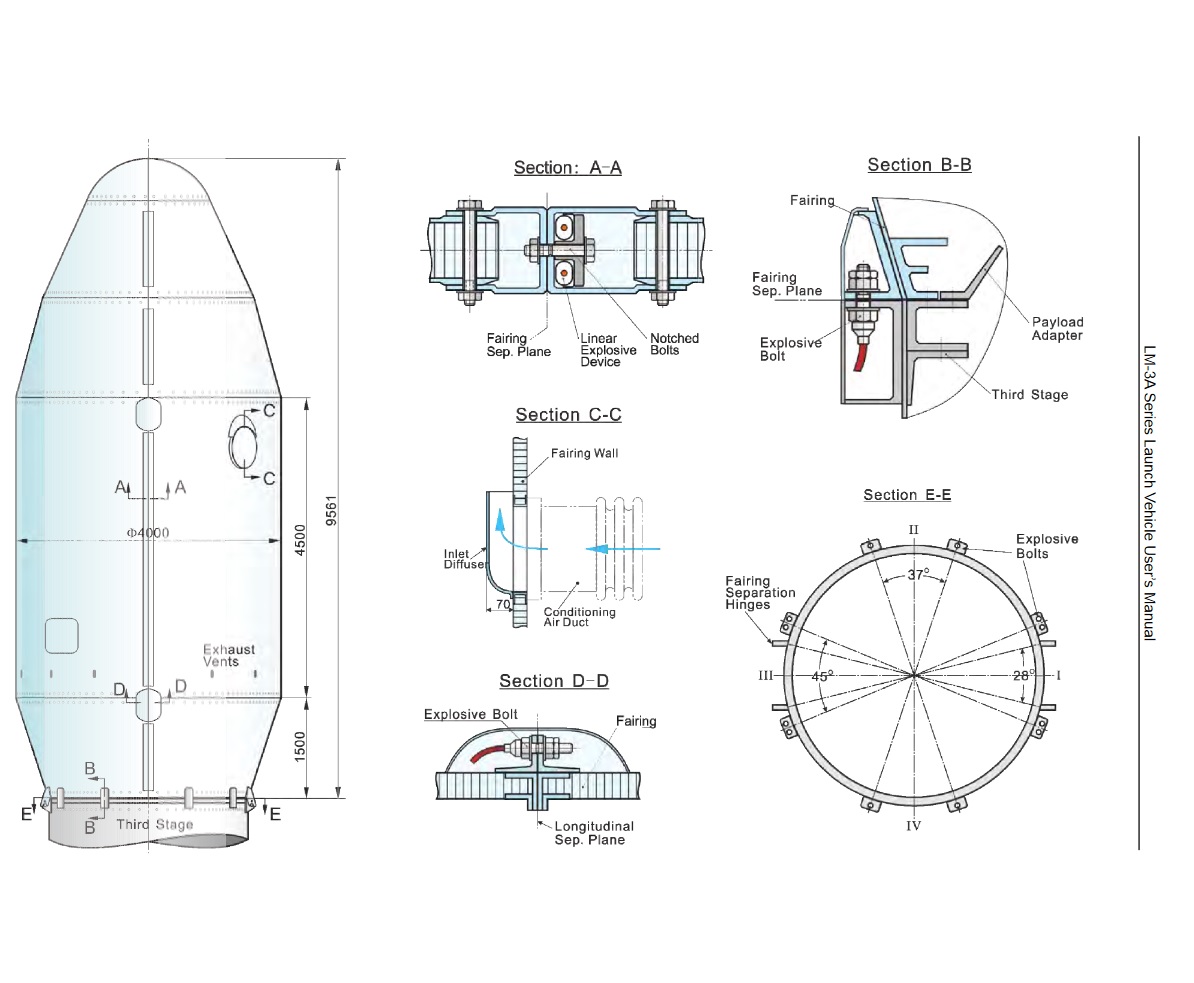

CP positioning on the fairing China Great Wall Industry Corporation:

An additional complication is the size of the fairings. It is approximately 15 meters by 5 meters. It can easily fit city bus. For the manufacture of metal fairings, special large CNC machines or very large autoclaves are used in the case of using composites. These processes are very resource-intensive and take a lot of time. Boeing's autoclave:

Well, you need to remember that after assembly, the fairing must go through a serious test, as it affects the survival rate of the monitors during the launch process. It is worth remembering that, as in the case of defects with a missile, a defect in the fairing will lead to the loss of safety procedures and the failure of the mission after the launch of the rocket, when the launch cannot be canceled.

Man on the background of the fairing for size comparison:

The fairing:

Sometimes when running thin instruments, fairings are required to create and maintain a clean room atmosphere inside the compartment. This imposes additional difficulties in designing fairings and contributes to an increase in price.

Update

Added additional information.

Hunting for fairings

At the moment, the price of fairings for missiles is about 5-7 million dollars. Many wonder: Why is it so expensive? It's just a piece of metal to protect. This is not entirely true; it is not just a piece of metal, although this design was made to protect the payload.

Let's start small. Each kilogram of fairing reduces the weight of the payload. Therefore, light composites with a reinforced structure with light alloys are used, usually aluminum alloys. The design resembles a honeycomb (isogrid). The weight of the Falcon 9 fairing with a diameter of 5.2 meters is about 1.9 tons.

By the choice of material also fit with special care, because the fairing should protect from the oncoming air flow, from EMI radiation, from temperature changes, from other vibrations and mechanical effects on MO. For example, the Falcon Heavy passes the sound barrier at an altitude of about 10 km, and then accelerates to 7-8 sweeps (2-3km / s). At these altitudes, the air is still quite dense and there is a strong warming up of the fairing with rapid cooling in the upper layers of the atmosphere. Temperature fluctuations can be from 100C to -100C in a short period of time (about a minute). Therefore, the material must be resistant to rapid temperature changes.

Using the example of the head fairing of a rocket, we consider the effect of aerodynamic heating on it. The figure shows the change in the convective heat flow in the nose of the fairing that occurs when braking the gas flow near the streamlined surface.

This heat flux causes heating of the surface of the head fairing (GO). The temperature distribution over the HE surface is shown in the following figure.

As can be seen from the figure, the temperature of the nose of the HE exceeds the permissible operating value for aluminum alloys. Therefore, an HRC made of asboplastic or fiberglass on a phenolic binder is applied to the outer surface of the nose of GO:

The temperature distribution of the structure of the HO having the HRC of the nose is shown in the figure:

It can be seen from the figure that both in the casing and in the longitudinal power set (stringers) the working temperature during the flight is within acceptable limits. However, for a spacecraft inside the GO, the heat flux from the design of the fairing may be unacceptable, as a result of which thermal insulation of the heated structure from the inner cavity of the GO is necessary.

The device of such thermal insulation (TI) is shown in the figure:

It is necessary to maintain the temperature 10-30С for the spacecraft under the fairing.

Also, the fairings should be able to ventilate so that, in the process of going out into space, the pressure inside the compartment must be equalized so that the fairing does not destroy the inside of ahead of time.

Another complication is that the fairings should be opened ideally so as not to damage the Mon and missile stages below them at a speed of about 3-4 km / s. That is, there must be a special mechanism for separating the fairings from Mon, without damaging the payload and the stage below it. A good video test of the Space X fairings in a vacuum chamber at the Glenn Research Institute, NASA:

For the opening of the fairing and for the separation of the steps as a whole, there is a separation system.

The separation system (CP) is designed for separation and removal from the trajectory of the removal of the exhaust stages, as well as for the garbage of structural elements that have fulfilled their functional purpose. Structural elements of the SR to act must ensure the integrity of the design of the PH and the perception of all loads. The operation of the CP elements is carried out very quickly, as a result of which sources of rapidly released energy (explosive, pressure accumulators, springs, etc.) are on board. After the operation of discontinuous elements, a complex dynamics of relative

motion occurs . The structure of the CP includes units, components and mechanisms that provide:

- reliable connection of separable parts and breaking of force bonds,

- dilution of separable parts.

The first group includes pyrozamki, pyrobolts pnevmozamki, mechanical locks, shell elements with linear detonating charges. Breeding is provided by pushers (pneumatic, pyro, spring), nozzles for pressurized gas, brake solid propellants, engine thrust.

Separation system pyrobolt:

Linear detonating projectile:

CP positioning on the fairing China Great Wall Industry Corporation:

An additional complication is the size of the fairings. It is approximately 15 meters by 5 meters. It can easily fit city bus. For the manufacture of metal fairings, special large CNC machines or very large autoclaves are used in the case of using composites. These processes are very resource-intensive and take a lot of time. Boeing's autoclave:

Well, you need to remember that after assembly, the fairing must go through a serious test, as it affects the survival rate of the monitors during the launch process. It is worth remembering that, as in the case of defects with a missile, a defect in the fairing will lead to the loss of safety procedures and the failure of the mission after the launch of the rocket, when the launch cannot be canceled.

Man on the background of the fairing for size comparison:

The fairing:

Sometimes when running thin instruments, fairings are required to create and maintain a clean room atmosphere inside the compartment. This imposes additional difficulties in designing fairings and contributes to an increase in price.

Update

Added additional information.