How does the life of a nuclear power plant end by the example of the Ignalina station?

The Ignalina nuclear power plant, located in Lithuania, is the second completely stopped NPP with RBMK (after Chernobyl). The reactors were finally shut down here on December 31, 2004 and December 31, 2009, and since then the nuclear power plant has been decommissioned (this euphemism implies dismantling, disposal of radioactive residues and cleaning up industrial facilities to the “green lawn”). This project (output) is actually a pilot for RBMK, and is based on several key process chains, of which one of the most important is the B234 plant, whose tests began in May 2017.

Ignalina NPP

Unlike Ukraine, Lithuania and especially, the 20-year-old reactors of the European Union behind the idea of decommissioning the EU have money for withdrawal, at least some of them. Nevertheless, the process of withdrawal of the Ingalinskaya NPP, which is rather thin on paper, has already become a soap opera. Since starting from 2019, Rosatom will have to carry out similar work (output of the 1.2 unit of the Leningrad NPP and then all RBMKs consistently), it is interesting to look at technologies, solutions and problems that have arisen around Ignalinki.

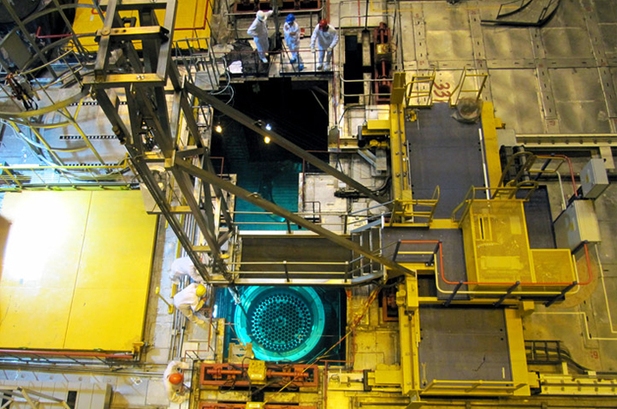

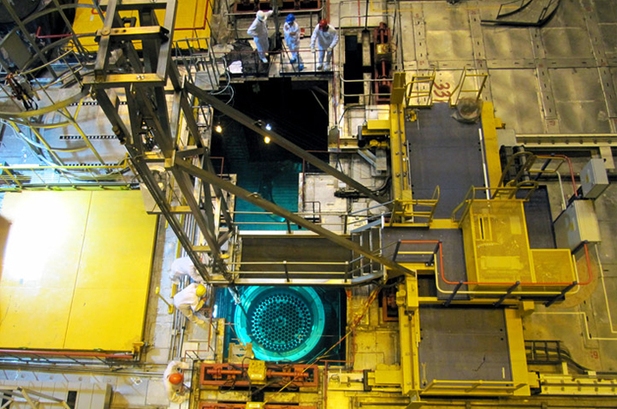

The process of transferring the SNF from the wet storage to the container CONSTOR, Ignalina NPP.

In general, the procedure of “immediate analysis” (that is, the station is being dismantled, in fact, after a month or two after stopping, using the station’s operating personnel) consists of the following important sections:

The process of monitoring the standards for radioactive contamination of scrap metal at the Ignalina NPP after decontamination (cleaning the surface).

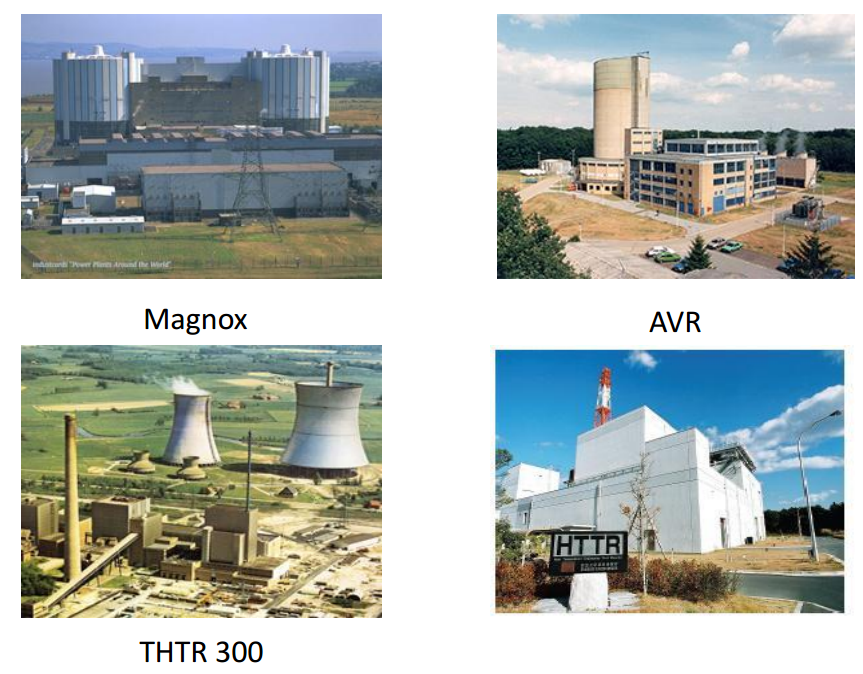

The main problems of RBMK and many other graphite reactors are graphite. Irradiated graphite has a specific activity of about 0.3-1 gigabekquerel per kg, including ~ 130 MBq / kg of the bad C14 isotope with a half-life of 5700 years. Because of C14, the annual limit of admission to the body according to safety standards is defined in 34 MBq of other options, except for the disposal of thousands of tons of graphite is not particularly visible, but the cost of this operation makes you think how to optimize it. In particular, for the first plutonium-producing reactors at Mayak, the Mining Chemical Combine and the SCC, it was decided to pour the graphite frame with concrete - i.e. organize a repository on the site of the reactor.

Some other types of reactors with graphite, which also have problems with its disposal.

At Ignalina NPP, this theoretical approach was implemented almost 1 to 1, at least at the project stage. Together with the decision to shut down the reactors, a withdrawal program was developed, which received about 80% of the EU finances and the rest was pledged to be funded by Lithuania itself. The plan envisaged construction of a new SNF storage facility in containers B1 ( my article on container and wet SNF storage facilities), a new plant for sorting and compactification of radioactive waste B234 , as well as two sites for radioactive waste - trench disposal for short-lived isotopes and very low-level radioactive waste B19and ground storage B25 for medium and low activity radioactive waste with “medium-lived” (we are talking about hundreds of years to a safe level) isotopes.

Appearance of the B34 waste recycling complex (B2 is a separate building, did not get into the frame)

Against the background of the construction of a new infrastructure for working with SNF and RW (it should be understood that SNF storages and RW storages already existed at the NPP, however, intended only for operation, and not for dismantling) the dismantling of the NPP auxiliary systems was to take place. At the same time, it was decided to postpone the resolution of the issue of radioactive graphite for the future until it is removed from the reactor and placed in storage.

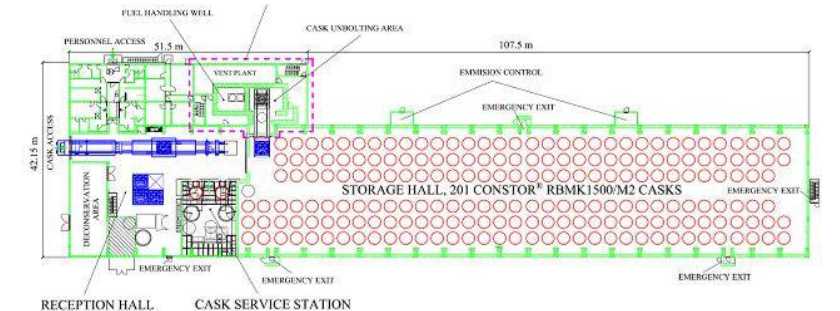

The storage facility that is already near the NPP is designed for 120 containers, each for 51 fuel assemblies, and today it is completely full.

The contract for the development and construction of B1 and B234 in 2005 was obtained by German Nukem Technologies, for the development of burial projects - various Lithuanian companies + Areva, the dismantling of the NPP systems was undertaken by the operating personnel of the NPP.

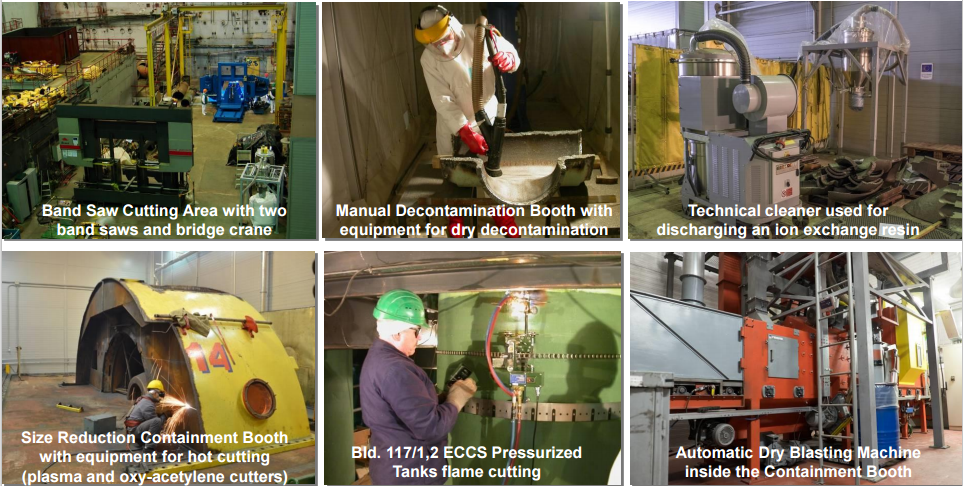

In particular, in the photographs - the result of dismantling ECCS in the building 117/2

Literally from the first days of the practice has ceased to be like a theory. The main problems arose around the B1 SNF storage, for many reasons at once. Nukem experienced organizational and financial problems at that time, Lithuania’s atomic supervision was not ready (in terms of the qualifications of its personnel) to sort out the decisions of German engineers around the storage of damaged SNF, and even the information on damaged SNF at the station turned out to be fragmentary and incomplete. Originally planned for delivery in 2009 (in order to start loading SNF 1 of the block after 5 years in the pools), the storage was completed only in 2015 and is only now being commissioned (in order to start reloading in 2018). All these delays led to repeated disputes between nuclear power plants and Nukem.

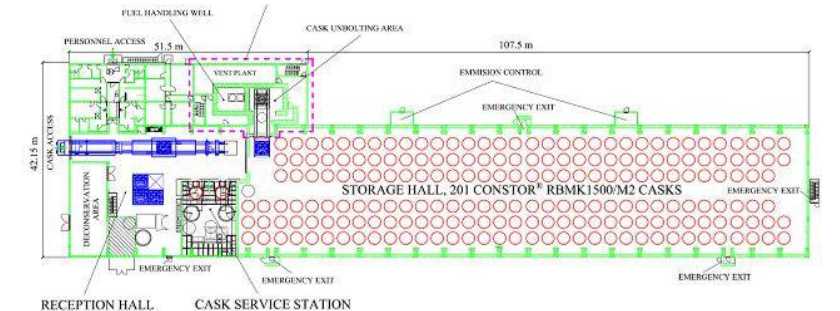

On the storage plan, B1 is marked with a purple frame where the radiation-hazardous work will be performed - closing (normal) and opening (non-standard) containers.

The rest of the work will be assigned to the existing “wet” storage.

Generally speaking, such a plot is not uncommon in the nuclear industry: many nuclear construction sites are monstrously delayed (and, as a result, they are becoming more expensive) due to design difficulties, which in turn is related to the inclusiveness of issues that developers and their supervisors from nuclear supervisors should keep track of. A typical example, except for Nukem, whose Lithuanian facilities are being commissioned with a 7-year (!) Lag and a rise of 1.5 times, is nearly destroyed the Areku 3 Olkiluoto unit with an EPR-1600 reactor, where the project management is not very good and lack understanding how to make a project under the strict requirements of the Finnish atomic surveillance STUK led to monstrous delays and cost overruns.

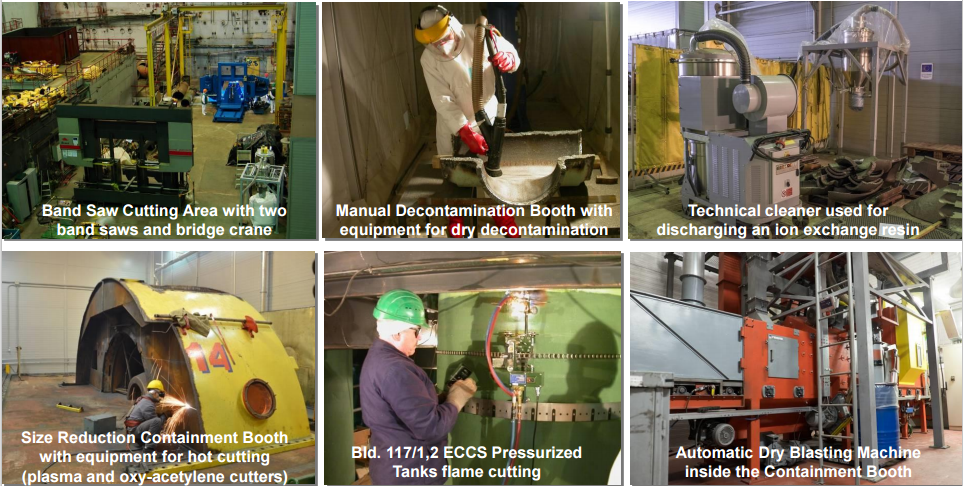

More about the process of dismantling nuclear power plants, clockwise - installation for cutting scrap metal, manual decontamination of surfaces, installation for cleaning liquids from radionuclides using ion exchange resins, cutting the housing of low-pressure cylinders of a turbine, separation of high-pressure cylinders, sand blasting chamber.

However, back to object B1. This is a covered container storage of SNF designed to overload RBMK fuel assemblies (or, more precisely, their halves, since RBMK fuel assemblies have a length of 10 meters, and in the fuel part are, in fact, 2 consecutive fuel assemblies on one suspension) into CONSTOR containers, each of which accommodates 182 halves of the fuel assembly. A total of 201 containers can be delivered at B1, designed for 34,200 standard “halves” and several hundred damaged ones, which will be stored in additional sealed canisters.

Before being transferred to storage in B1, all fuel assemblies removed from reactors (by the way, only the first unit is released from fuel at the nuclear power plant, the second still has more than 1000 fuel assemblies due to the lack of space in the aging pools) for at least 5 years are kept centrally wet storage, they are also unpacked and packed under water in CONSTOR containers, for which, by the way, the fuel assembly repository has to be modified - cranes, container installation units, transfer equipment (I am writing this phrase for Ukrainian fans that it’s possible to but loaded into any container without much effort).

In general, storage in the container is carried out according to the standard scheme - a stainless steel basket with fuel assembly in a sealed brewed container filled with dry nitrogen, placed in an external massive metal-concrete container (for bio-protection). Taking into account the fact that the most recent fuel assemblies have been endured for 8 years, the complexity of transport and technological operations for the refueling of fuel assemblies between numerous facilities, penalizing damaged SNF, and minimizing the personnel dose during these operations is not

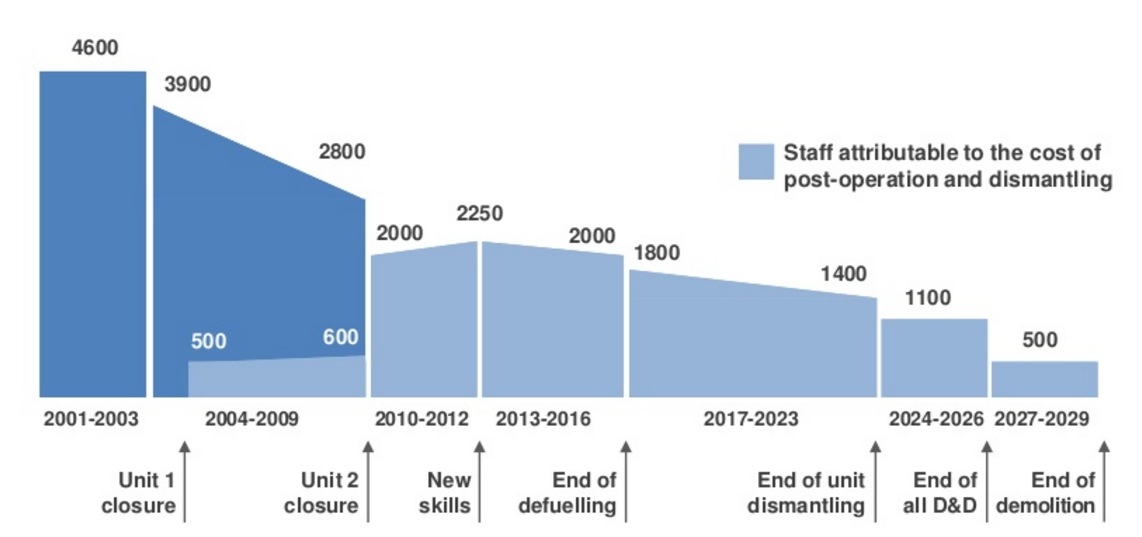

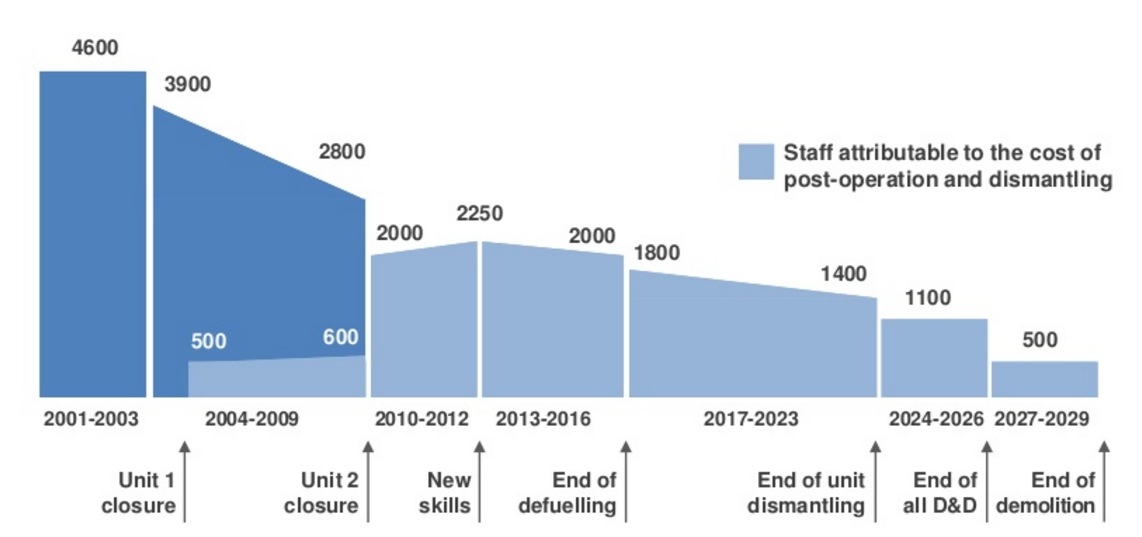

interesting for the Russian nuclear power plant workers with RBMK dynamics of the number of personnel at the Ignalina NPP in the process of dismantling

However, this is in theory. So, for example, the first version of the CONSTOR container for ISF B1 was rejected on the basis of biosecurity characteristics, after which the manufacturer (German company GNS) was forced to develop and license another version, which contributed to the launch delay B1.

In total, at the Ignalina NPP today, about ~ 22,000 fuel assemblies of SNF (that is, 44,000 halves) and the remaining part will be stored in another dry SNF storage facility built in 1999.

Photos of the IAEA's wet storage facility. 15,000 fuel assemblies are now stored here, although it seems to me that the photo does not show the fuel assembly but additional absorbers or control rods

Lithuanians are considering the possibility of final geological disposal at a depth of> 500 meters (as recommended by the IAEA), but for the next 50 years, with the possibility of extension to 100, apparently, the SNF will be stored in the constructed SNFS.

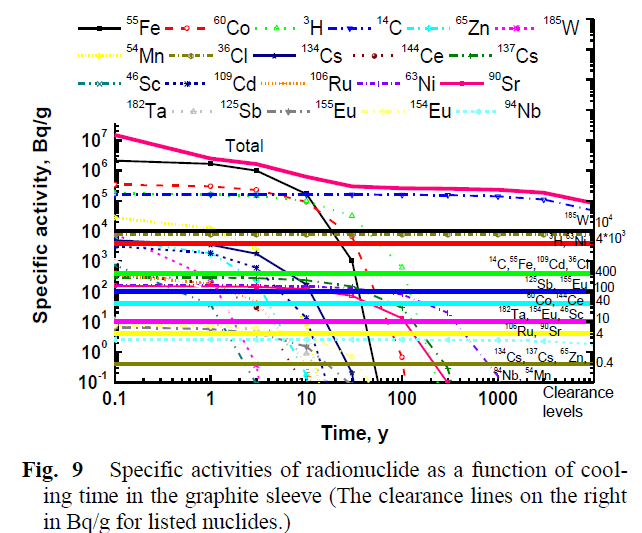

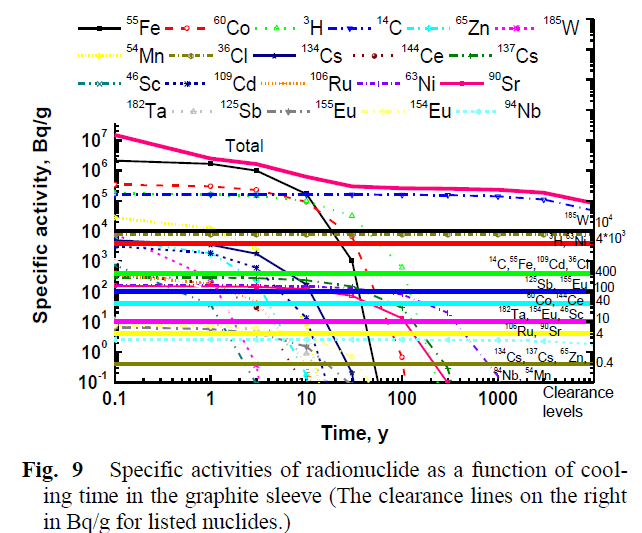

On the issue of storage time - calculated values of the radionuclide content in activated graphite of RBMK masonry, in Becquerel per gram. Horizontal lines are permissible values releasing from the category of radioactive waste, the pink line above is the total content of radionuclides. It can be seen that after several decades of luminescence, activity is determined mainly by the C14 isotope

The second important object - the radioactive waste management plant B234 arose not only to work with construction waste arising from the dismantling of nuclear power plants, but also because of the new classification of radioactive waste introduced in the EU, because of which the existing volume of radioactive waste ( these are filters, used overalls, cemented HRAO, etc.) need to be re-sorted and determined for burial or storage.

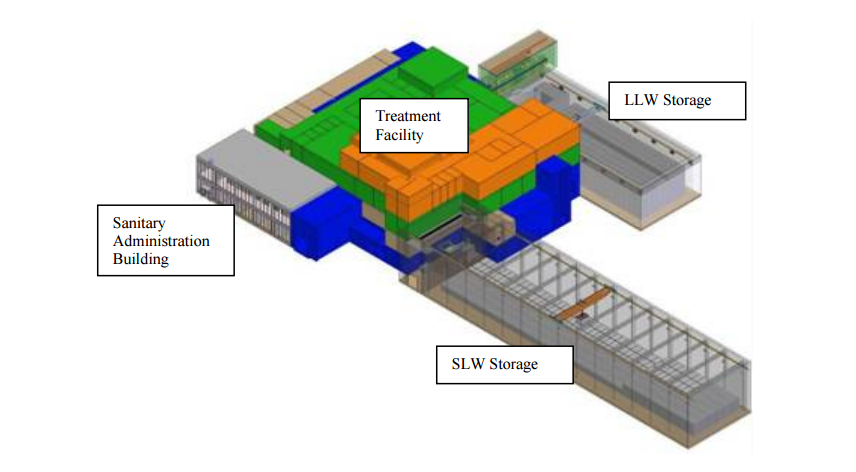

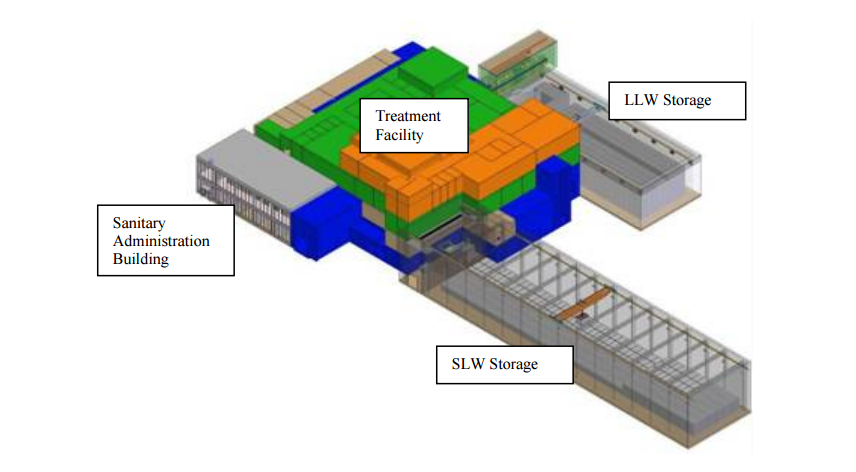

General view of B34. Left - sanitary inspection room, in the middle the actual plant, to which intermediate storage facilities of low level waste (SLW) and intermediate level waste (LLW) are attached

The operation of this plant is based on the processes of sorting (unsurprisingly), incineration and cementation, compactification (ie, pressing, mainly scrap) and packaging in containers that will be stored at intermediate storage facilities for radioactive waste (included in B234) until readiness B19 and B25. An interesting feature of the plant is its high automation, using the familiar Brokk robots and Walischmiller manipulators.

Some remote-controlled equipment B234 The

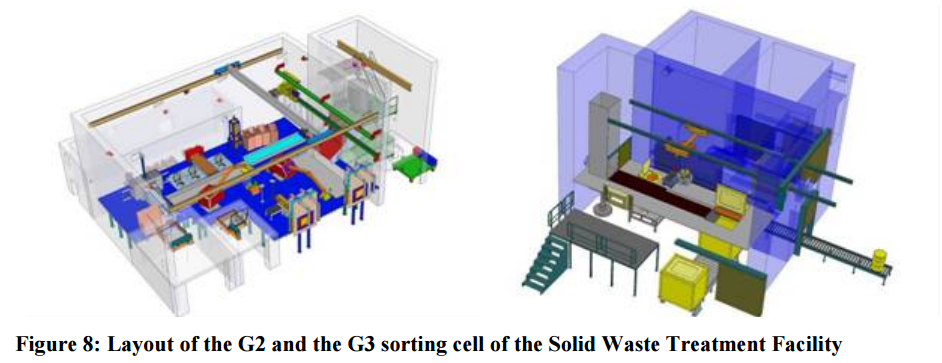

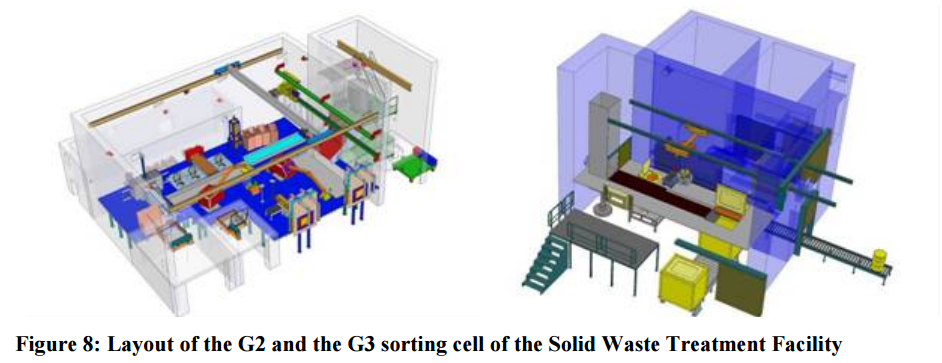

design of the incineration plant-compactification of ash and cell sorting for intermediate level and low level waste.

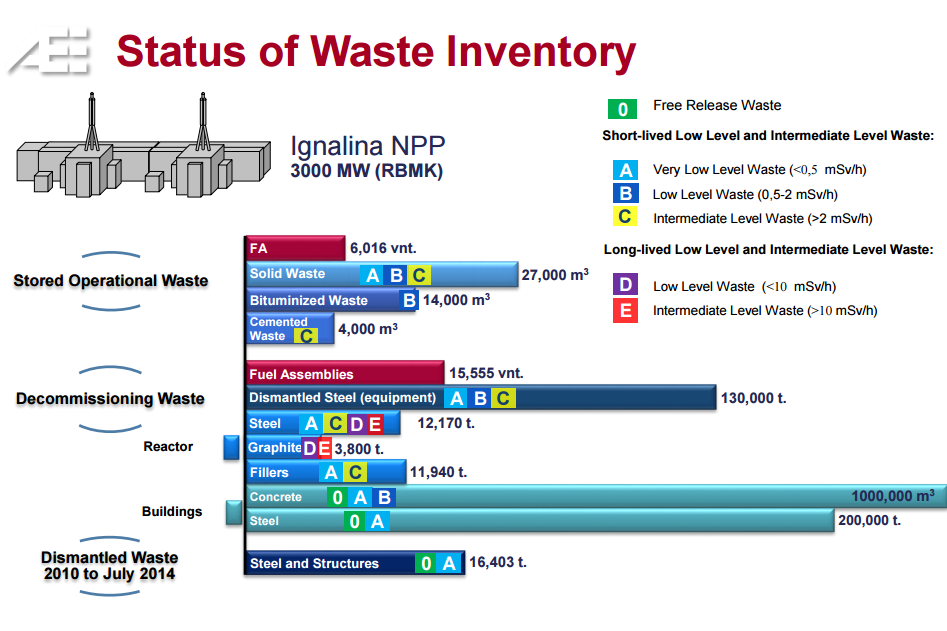

The total amount of waste that passes through this plant amounts to hundreds of thousands of cubic meters, which will be divided into 6 new classes of radioactive waste (A, B, C, D, E, F), but the estimates are still preliminary.

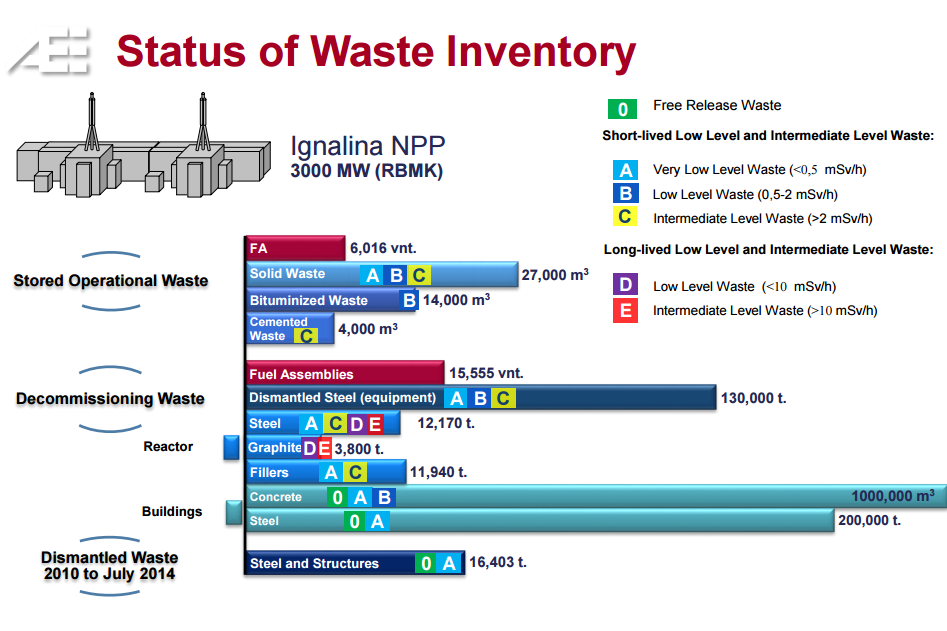

Estimation of total waste and classes of radioactive waste.

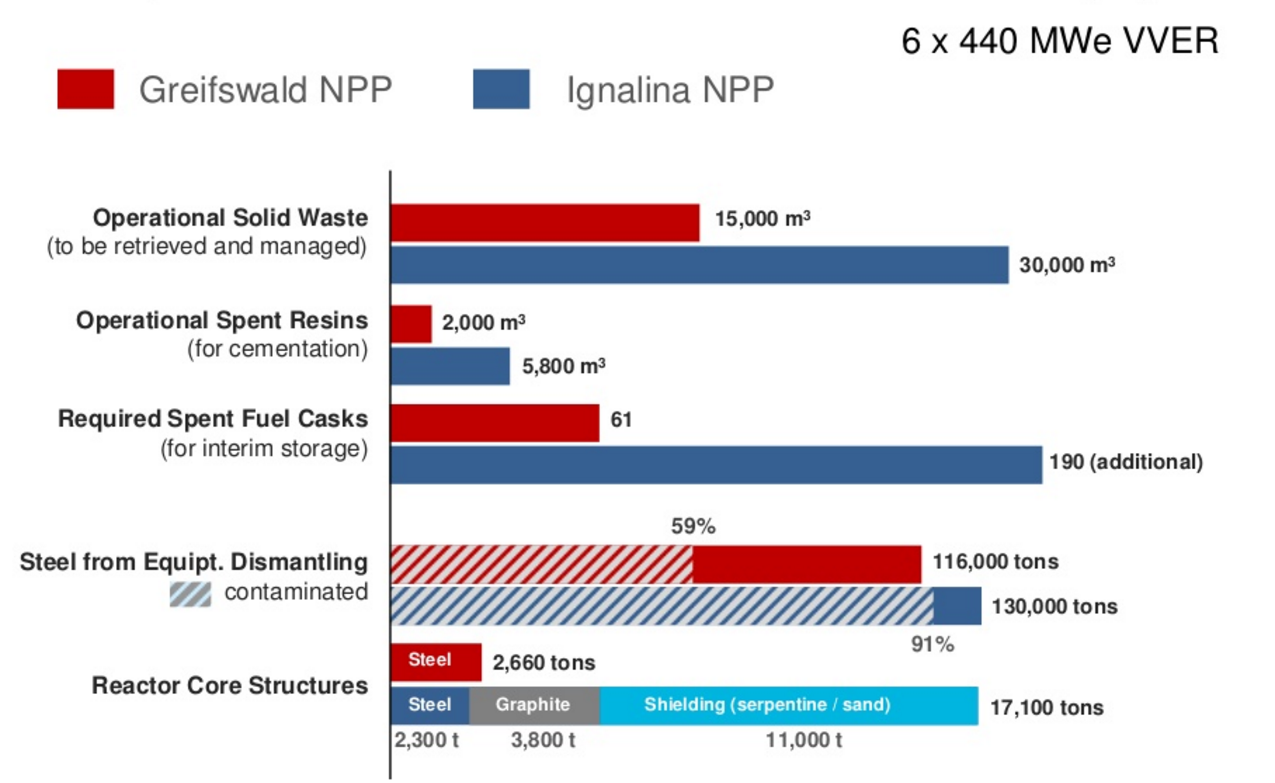

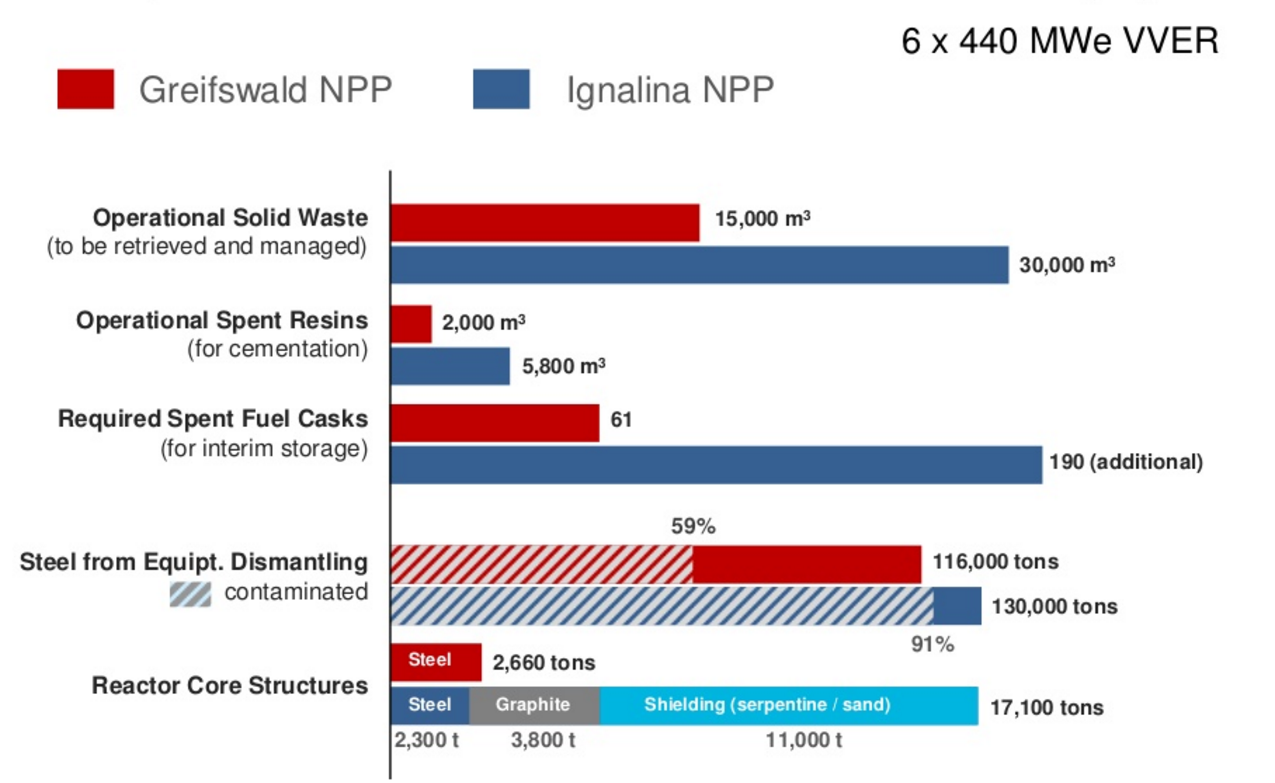

For comparison, the units with WWER during the withdrawal give noticeably smaller volumes of radioactive waste and structures (to the question of the "RBMK deshivizne").

Comparison of nuclear power plants with 6хВВЭР-440 and 2 RBMK-1500 by the volume of waste generated in the process.

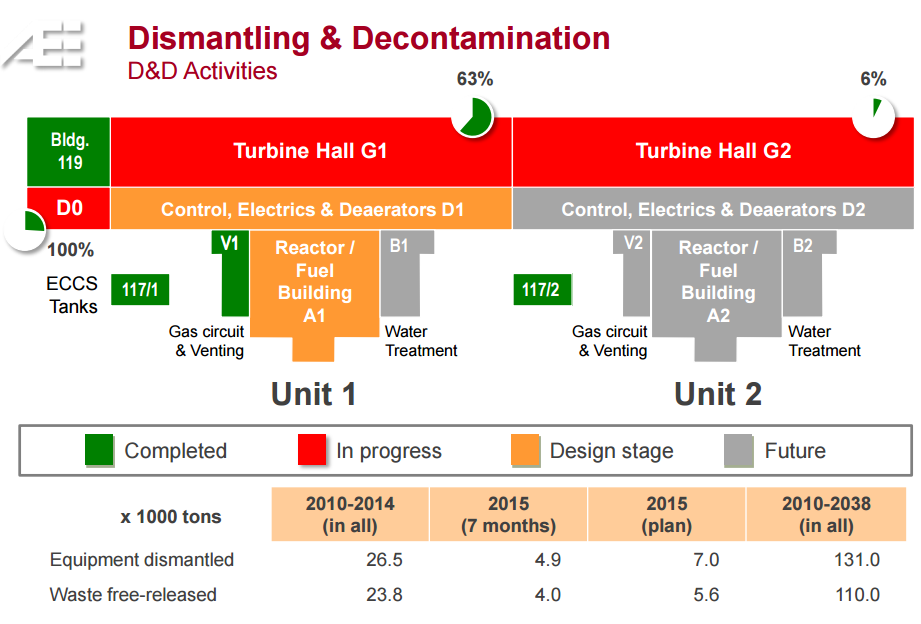

As for the process of dismantling the equipment of nuclear power plants, today this process has mainly affected the first unit (where the status of a nuclear hazard facility has been removed), where the equipment is being cut at a rate of ~ 5-8 thousand tons per year. According to today's plans, the complete dismantling of nuclear power plants should be completed in 2038, but this period has already been postponed twice. Interestingly, the administration of the nuclear power plant estimates the income from the sale of materials obtained when dismantling nuclear power plants at only 30 million euros.

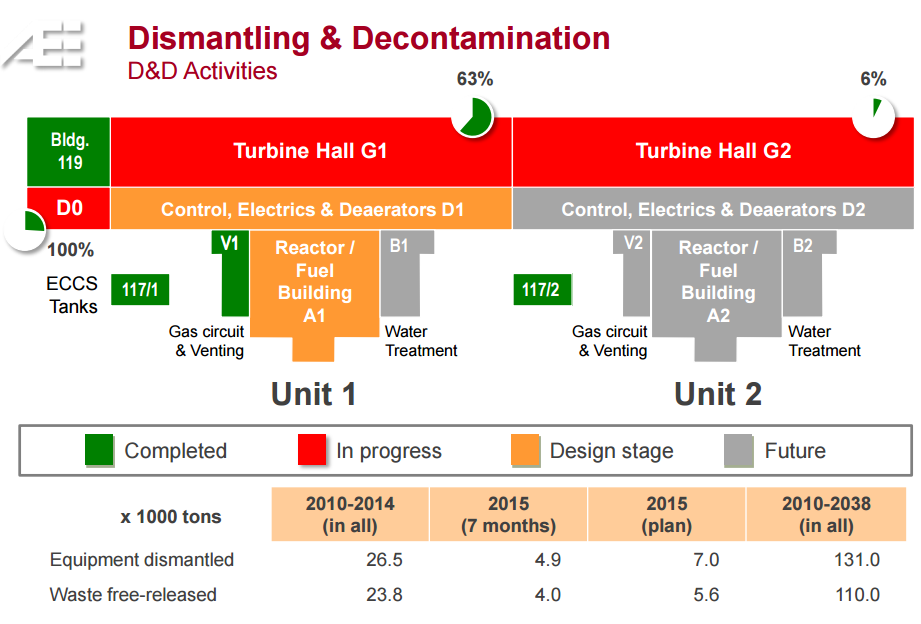

The current status of nuclear power plant disassembly is green, what has already been done, red is in progress, yellow is the design of operations, gray is not affected yet.

The experience of the Ignalina NPP is interesting for its applicability in Russia, where disassembly of 8 RBMK units will begin until 2030. Considering that Nukem has been owned by Rosatom since 2009, it turns out experience for European money, and now this experience is being broadcast to other Rosatom structures that will decommission RBMK. This experience is also interesting for the potential market of contracts for decommissioning various NPPs, the number of which will increase.

Ignalina NPP

Unlike Ukraine, Lithuania and especially, the 20-year-old reactors of the European Union behind the idea of decommissioning the EU have money for withdrawal, at least some of them. Nevertheless, the process of withdrawal of the Ingalinskaya NPP, which is rather thin on paper, has already become a soap opera. Since starting from 2019, Rosatom will have to carry out similar work (output of the 1.2 unit of the Leningrad NPP and then all RBMKs consistently), it is interesting to look at technologies, solutions and problems that have arisen around Ignalinki.

The process of transferring the SNF from the wet storage to the container CONSTOR, Ignalina NPP.

In general, the procedure of “immediate analysis” (that is, the station is being dismantled, in fact, after a month or two after stopping, using the station’s operating personnel) consists of the following important sections:

- Unloading of fuel from the reactor, storage pools in the SNF storage facility to ensure the nuclear safety of the reactor and the reactor hall with the ability to stop the flow of cooling water to the reactor and BV. In addition to the standard SNF, such work should be carried out with damaged SNF, which should be penalized before displacement and with all sorts of radioactive replaceable elements of the reactor - for example, additional absorbers. The whole procedure takes from 2-3 years to infinity, if there are problems with ISFL.

- In parallel, the dismantling of auxiliary systems of nuclear power plants begins - for example, pumping stations, technical gas shops, in the case of RBMK it is still a huge construction of a gas Reactor Emergency Cooling System, a generator with auxiliary systems.

- At the same time, infrastructure is being prepared for future intermediate level radioactive waste (RW) - this is near-site or remote near-surface repository, which is a concrete trench covered with clay and soil above. The CAO from NPPs will be many, it is a noticeable part of the primary circuit and systems associated with the reactor.

- After the infrastructure is ready, you can begin to disassemble NPP elements that may carry radioactive contamination or activation, sorted by activity level and attempts to wash off surface contamination. What manages to clean up to standards - goes to scrap, that is not - in the burial. It is still not known exactly how much buried SAOs will be from the RBMK, so that it will be determined, at least one must be dismantled.

The process of monitoring the standards for radioactive contamination of scrap metal at the Ignalina NPP after decontamination (cleaning the surface).

The main problems of RBMK and many other graphite reactors are graphite. Irradiated graphite has a specific activity of about 0.3-1 gigabekquerel per kg, including ~ 130 MBq / kg of the bad C14 isotope with a half-life of 5700 years. Because of C14, the annual limit of admission to the body according to safety standards is defined in 34 MBq of other options, except for the disposal of thousands of tons of graphite is not particularly visible, but the cost of this operation makes you think how to optimize it. In particular, for the first plutonium-producing reactors at Mayak, the Mining Chemical Combine and the SCC, it was decided to pour the graphite frame with concrete - i.e. organize a repository on the site of the reactor.

Some other types of reactors with graphite, which also have problems with its disposal.

At Ignalina NPP, this theoretical approach was implemented almost 1 to 1, at least at the project stage. Together with the decision to shut down the reactors, a withdrawal program was developed, which received about 80% of the EU finances and the rest was pledged to be funded by Lithuania itself. The plan envisaged construction of a new SNF storage facility in containers B1 ( my article on container and wet SNF storage facilities), a new plant for sorting and compactification of radioactive waste B234 , as well as two sites for radioactive waste - trench disposal for short-lived isotopes and very low-level radioactive waste B19and ground storage B25 for medium and low activity radioactive waste with “medium-lived” (we are talking about hundreds of years to a safe level) isotopes.

Appearance of the B34 waste recycling complex (B2 is a separate building, did not get into the frame)

Against the background of the construction of a new infrastructure for working with SNF and RW (it should be understood that SNF storages and RW storages already existed at the NPP, however, intended only for operation, and not for dismantling) the dismantling of the NPP auxiliary systems was to take place. At the same time, it was decided to postpone the resolution of the issue of radioactive graphite for the future until it is removed from the reactor and placed in storage.

The storage facility that is already near the NPP is designed for 120 containers, each for 51 fuel assemblies, and today it is completely full.

The contract for the development and construction of B1 and B234 in 2005 was obtained by German Nukem Technologies, for the development of burial projects - various Lithuanian companies + Areva, the dismantling of the NPP systems was undertaken by the operating personnel of the NPP.

In particular, in the photographs - the result of dismantling ECCS in the building 117/2

Literally from the first days of the practice has ceased to be like a theory. The main problems arose around the B1 SNF storage, for many reasons at once. Nukem experienced organizational and financial problems at that time, Lithuania’s atomic supervision was not ready (in terms of the qualifications of its personnel) to sort out the decisions of German engineers around the storage of damaged SNF, and even the information on damaged SNF at the station turned out to be fragmentary and incomplete. Originally planned for delivery in 2009 (in order to start loading SNF 1 of the block after 5 years in the pools), the storage was completed only in 2015 and is only now being commissioned (in order to start reloading in 2018). All these delays led to repeated disputes between nuclear power plants and Nukem.

On the storage plan, B1 is marked with a purple frame where the radiation-hazardous work will be performed - closing (normal) and opening (non-standard) containers.

The rest of the work will be assigned to the existing “wet” storage.

Generally speaking, such a plot is not uncommon in the nuclear industry: many nuclear construction sites are monstrously delayed (and, as a result, they are becoming more expensive) due to design difficulties, which in turn is related to the inclusiveness of issues that developers and their supervisors from nuclear supervisors should keep track of. A typical example, except for Nukem, whose Lithuanian facilities are being commissioned with a 7-year (!) Lag and a rise of 1.5 times, is nearly destroyed the Areku 3 Olkiluoto unit with an EPR-1600 reactor, where the project management is not very good and lack understanding how to make a project under the strict requirements of the Finnish atomic surveillance STUK led to monstrous delays and cost overruns.

More about the process of dismantling nuclear power plants, clockwise - installation for cutting scrap metal, manual decontamination of surfaces, installation for cleaning liquids from radionuclides using ion exchange resins, cutting the housing of low-pressure cylinders of a turbine, separation of high-pressure cylinders, sand blasting chamber.

However, back to object B1. This is a covered container storage of SNF designed to overload RBMK fuel assemblies (or, more precisely, their halves, since RBMK fuel assemblies have a length of 10 meters, and in the fuel part are, in fact, 2 consecutive fuel assemblies on one suspension) into CONSTOR containers, each of which accommodates 182 halves of the fuel assembly. A total of 201 containers can be delivered at B1, designed for 34,200 standard “halves” and several hundred damaged ones, which will be stored in additional sealed canisters.

Before being transferred to storage in B1, all fuel assemblies removed from reactors (by the way, only the first unit is released from fuel at the nuclear power plant, the second still has more than 1000 fuel assemblies due to the lack of space in the aging pools) for at least 5 years are kept centrally wet storage, they are also unpacked and packed under water in CONSTOR containers, for which, by the way, the fuel assembly repository has to be modified - cranes, container installation units, transfer equipment (I am writing this phrase for Ukrainian fans that it’s possible to but loaded into any container without much effort).

In general, storage in the container is carried out according to the standard scheme - a stainless steel basket with fuel assembly in a sealed brewed container filled with dry nitrogen, placed in an external massive metal-concrete container (for bio-protection). Taking into account the fact that the most recent fuel assemblies have been endured for 8 years, the complexity of transport and technological operations for the refueling of fuel assemblies between numerous facilities, penalizing damaged SNF, and minimizing the personnel dose during these operations is not

interesting for the Russian nuclear power plant workers with RBMK dynamics of the number of personnel at the Ignalina NPP in the process of dismantling

However, this is in theory. So, for example, the first version of the CONSTOR container for ISF B1 was rejected on the basis of biosecurity characteristics, after which the manufacturer (German company GNS) was forced to develop and license another version, which contributed to the launch delay B1.

In total, at the Ignalina NPP today, about ~ 22,000 fuel assemblies of SNF (that is, 44,000 halves) and the remaining part will be stored in another dry SNF storage facility built in 1999.

Photos of the IAEA's wet storage facility. 15,000 fuel assemblies are now stored here, although it seems to me that the photo does not show the fuel assembly but additional absorbers or control rods

Lithuanians are considering the possibility of final geological disposal at a depth of> 500 meters (as recommended by the IAEA), but for the next 50 years, with the possibility of extension to 100, apparently, the SNF will be stored in the constructed SNFS.

On the issue of storage time - calculated values of the radionuclide content in activated graphite of RBMK masonry, in Becquerel per gram. Horizontal lines are permissible values releasing from the category of radioactive waste, the pink line above is the total content of radionuclides. It can be seen that after several decades of luminescence, activity is determined mainly by the C14 isotope

The second important object - the radioactive waste management plant B234 arose not only to work with construction waste arising from the dismantling of nuclear power plants, but also because of the new classification of radioactive waste introduced in the EU, because of which the existing volume of radioactive waste ( these are filters, used overalls, cemented HRAO, etc.) need to be re-sorted and determined for burial or storage.

General view of B34. Left - sanitary inspection room, in the middle the actual plant, to which intermediate storage facilities of low level waste (SLW) and intermediate level waste (LLW) are attached

The operation of this plant is based on the processes of sorting (unsurprisingly), incineration and cementation, compactification (ie, pressing, mainly scrap) and packaging in containers that will be stored at intermediate storage facilities for radioactive waste (included in B234) until readiness B19 and B25. An interesting feature of the plant is its high automation, using the familiar Brokk robots and Walischmiller manipulators.

Some remote-controlled equipment B234 The

design of the incineration plant-compactification of ash and cell sorting for intermediate level and low level waste.

The total amount of waste that passes through this plant amounts to hundreds of thousands of cubic meters, which will be divided into 6 new classes of radioactive waste (A, B, C, D, E, F), but the estimates are still preliminary.

Estimation of total waste and classes of radioactive waste.

For comparison, the units with WWER during the withdrawal give noticeably smaller volumes of radioactive waste and structures (to the question of the "RBMK deshivizne").

Comparison of nuclear power plants with 6хВВЭР-440 and 2 RBMK-1500 by the volume of waste generated in the process.

As for the process of dismantling the equipment of nuclear power plants, today this process has mainly affected the first unit (where the status of a nuclear hazard facility has been removed), where the equipment is being cut at a rate of ~ 5-8 thousand tons per year. According to today's plans, the complete dismantling of nuclear power plants should be completed in 2038, but this period has already been postponed twice. Interestingly, the administration of the nuclear power plant estimates the income from the sale of materials obtained when dismantling nuclear power plants at only 30 million euros.

The current status of nuclear power plant disassembly is green, what has already been done, red is in progress, yellow is the design of operations, gray is not affected yet.

The experience of the Ignalina NPP is interesting for its applicability in Russia, where disassembly of 8 RBMK units will begin until 2030. Considering that Nukem has been owned by Rosatom since 2009, it turns out experience for European money, and now this experience is being broadcast to other Rosatom structures that will decommission RBMK. This experience is also interesting for the potential market of contracts for decommissioning various NPPs, the number of which will increase.