Pressure is OK: Why does the data center need air pressure control?

Everything should be perfect in a person, but in a modern data center everything should work like a Swiss watch. Not a single component of the complex architecture of data center engineering systems should be left without the attention of the operating service. It was these considerations that we were guided by at the Linxdatacenter site in St. Petersburg, preparing for the certification of Uptime Management & Operations in 2018 and bringing all data center systems in line with the best international standards.

Today I will tell you how and why we introduced the system of remote control of pressure and air “back-up” in the server rooms. Let me remind you that in the process of preparing for the audit of the Uptime Institute, one of the tasks to be solved was the issue of cleanliness. Our team worked in two areas: cleaning (previously my colleague already toldabout how we fought dust in server rooms) and pressure control in server rooms. As the chief engineer of the company, the second was just assigned to me.

What are we talking about

In any server room there is a system of general ventilation. It is designed very simply: one ventilation machine works to supply air inward, the second - to extract it outward. Both engines are controlled by frequency controllers, that is, it is possible to change the frequency of their revolutions and thereby regulate the volumes of supplied / removed air.

There are two tasks for this system:

- Provide the required air exchange for a comfortable stay of people in the server room (the number of people is set based on the specifics of the room),

- Provide excess air pressure in the server room so that dust particles are not drawn into the room through open doors and maintain the necessary cleanliness.

The supply ventilation machine must supply more air to the server room than is discharged by the hood. This provides excess pressure in the server room in relation to neighboring rooms - the so-called "air pressure". With such a system, air enters the server room only through the supply ventilation filters, and the supply of unfiltered air to the server room is excluded.

If suddenly everything happens the other way around - exhaust ventilation removes more air than the supply air supply - then unfiltered air starts to enter the server room from adjacent rooms, which is often the cause of dust on surfaces and on equipment.

No control

Everything seems to be simple. However, at the time the work began to improve the quality of cleaning in the data center, we did not have an effective tool for monitoring the presence of backwater. We set the feed frequency more than the draw frequency, and then we made a further adjustment “by eye”. The doors to the server room open with difficulty (as if attracted inward) - the backwater is negative. If on the contrary - the closer does not cope with closing - it means that the backwater is very strong. Groping a certain balance between these two states, somewhere in the middle we stopped.

However, this approach is unreliable, and we found it impossible to rely on it further.

Why? Working "by eye", it is impossible to take into account the influence of the state of air filters on the power of the supply ventilation. If the filter is clean, we will see certain indicators of resistance and the volume of air supplied, if the filter is dirty, then these indicators will differ markedly. The dynamics of opening and closing the door, these nuances can not be traced.

Typically, the filter is replaced by a standard mechanical differential pressure gauge, which turns off ventilation at a certain stage of filter contamination (the pressure difference before and after the filter should not exceed a certain indicator that corresponds to the filter cleanliness norm).

It turns out that there is a long period of filter life, while it is gradually becoming dirty, and the standard differential ventilation pressure gauge considers it suitable for work. But the ventilation power and, consequently, the backwater force vary depending on the state of the filter.

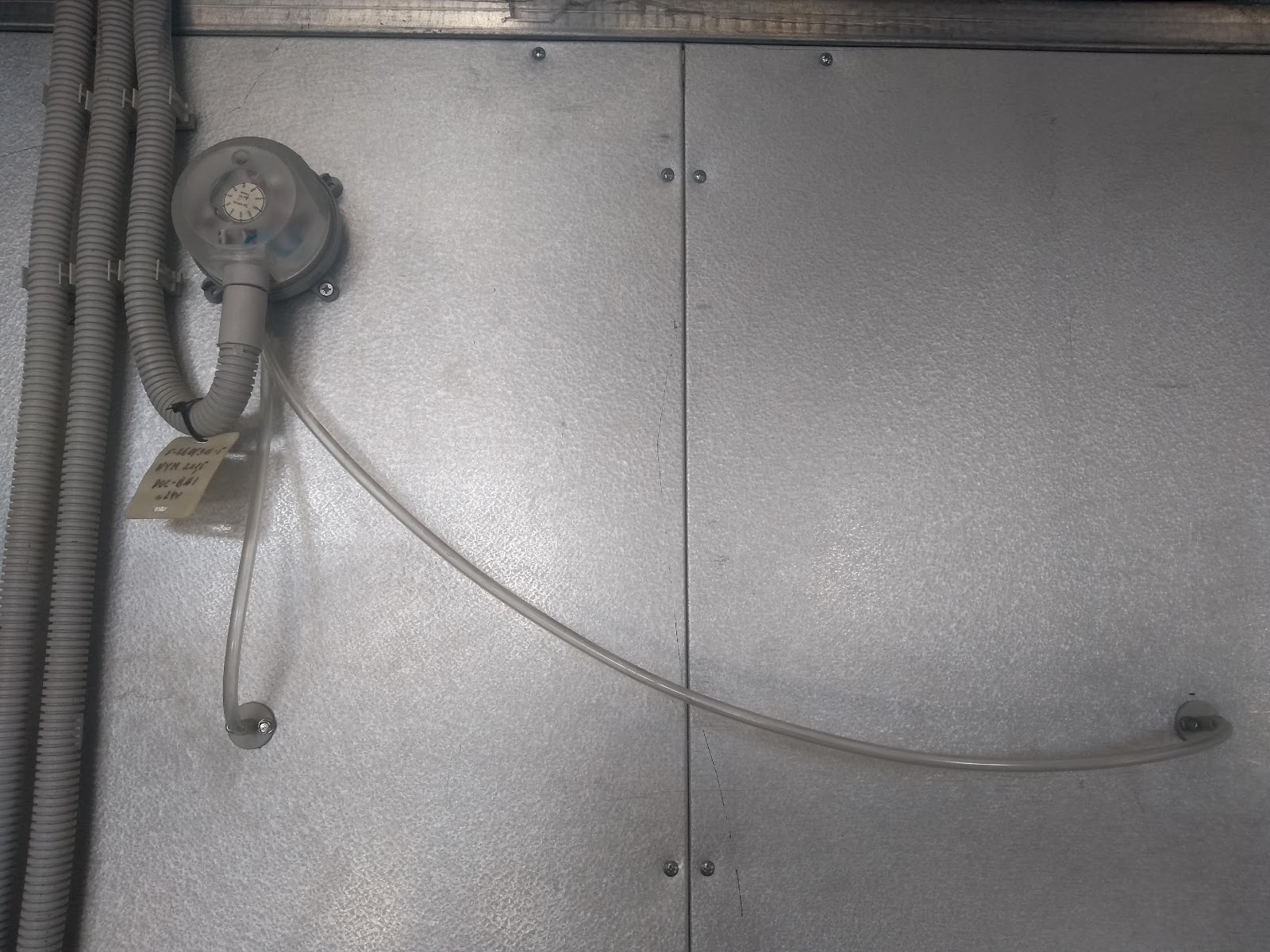

Native ventilation diffmanometer.

As a result, we came to the conclusion that the process of setting up and controlling backwater in such a scenario is too complicated and again ineffective for the data center.

Decision

For the answer to the question “What should we do?” We turned to the best world practices, which was helped by a trip to Stockholm with a tour of the local data centers.

In one of the data centers we saw the solution we needed - a mechanical diffmanometer was installed at the entrance to the server room and showed the pressure difference "server / corridor".

Interestingly, Swedish colleagues use diffmanometers at the entrance to the server ones and to control the contamination of the ventilation filter: they change the filters when the back pressure decreases, they did not wait for a signal from the standard diffmanometer of the ventilation system. The readings of the manometer visually monitor the attendants on the rounds.

Having returned, we began to look for similar equipment in Russia. It turned out that such diffanometers are used in our so-called "clean rooms", that is, in operating rooms, laboratories, etc. Due to the special status of the premises, the prices for this equipment were sky-high.

In addition, we needed not an analog device, but a digital one, preferably with an output of 4-20mA, so that we could connect it to the monitoring center of the data center. This was important for setting thresholds for sending alerts, and for collecting and analyzing statistics.

Who seeks will always find

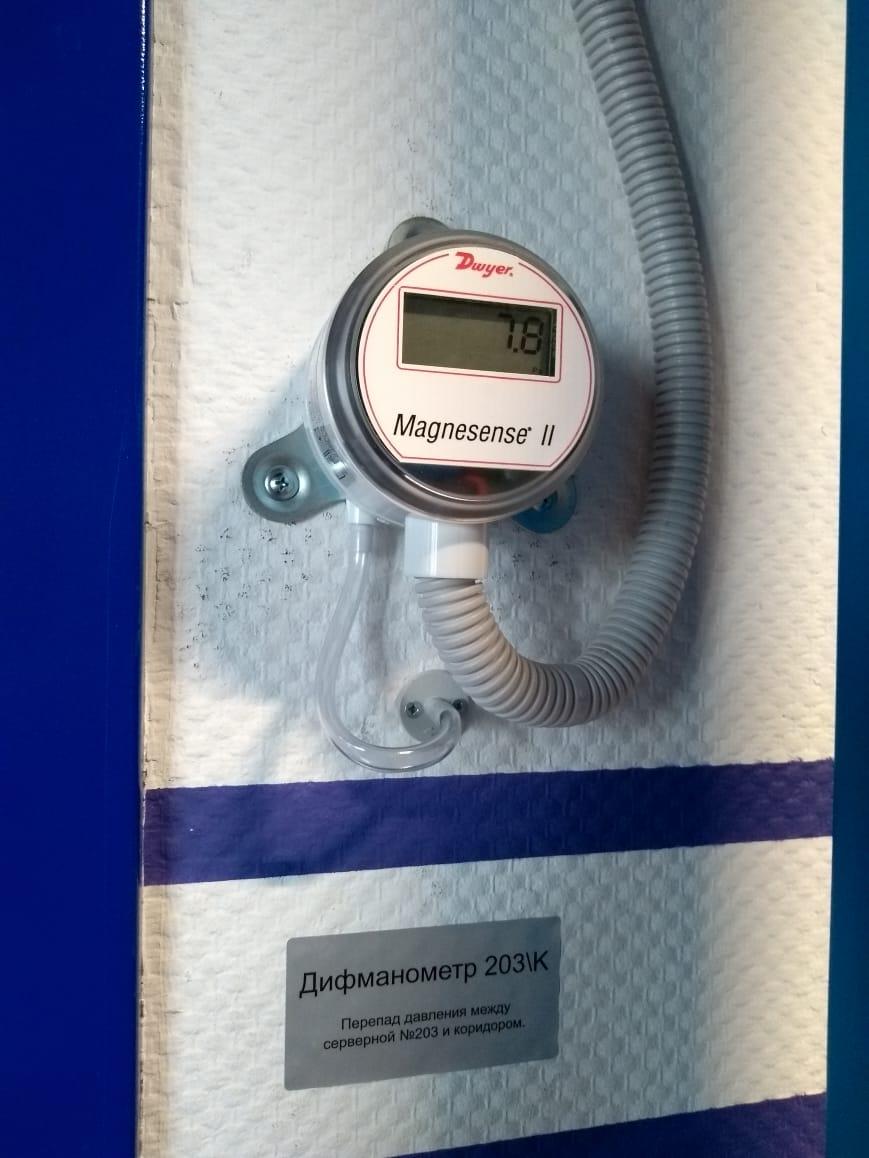

We were lucky - soon after the start of the search we managed to find the necessary device: a digital differential pressure gauge with a screen and an output for connecting to the BMS with a budget of about 10,000 rubles per unit.

We have installed, configured and are surprised only by one thing - why we hadn’t guessed it before ourselves, and why this solution is not standard in data center projects.

It looks like this:

An electronic diffmanometer in the corridor outside the server room, the tube of one measuring channel is led into the server room, the second channel measures the pressure in the corridor.

And so the device is displayed in the data center monitoring system:

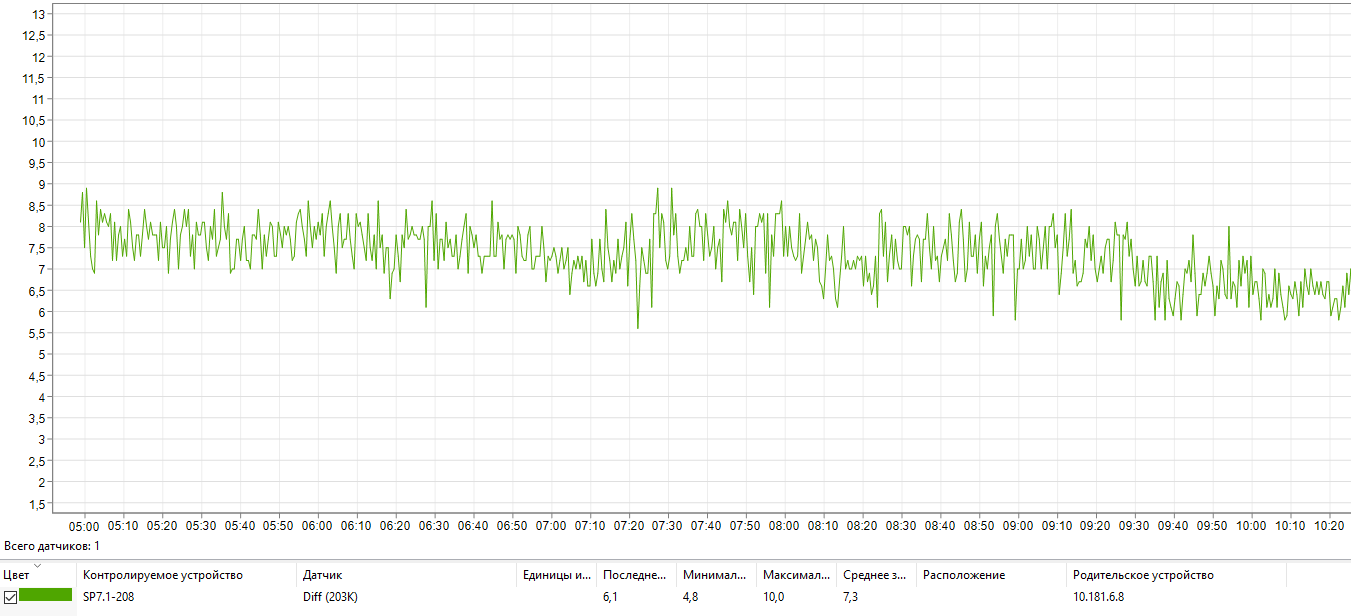

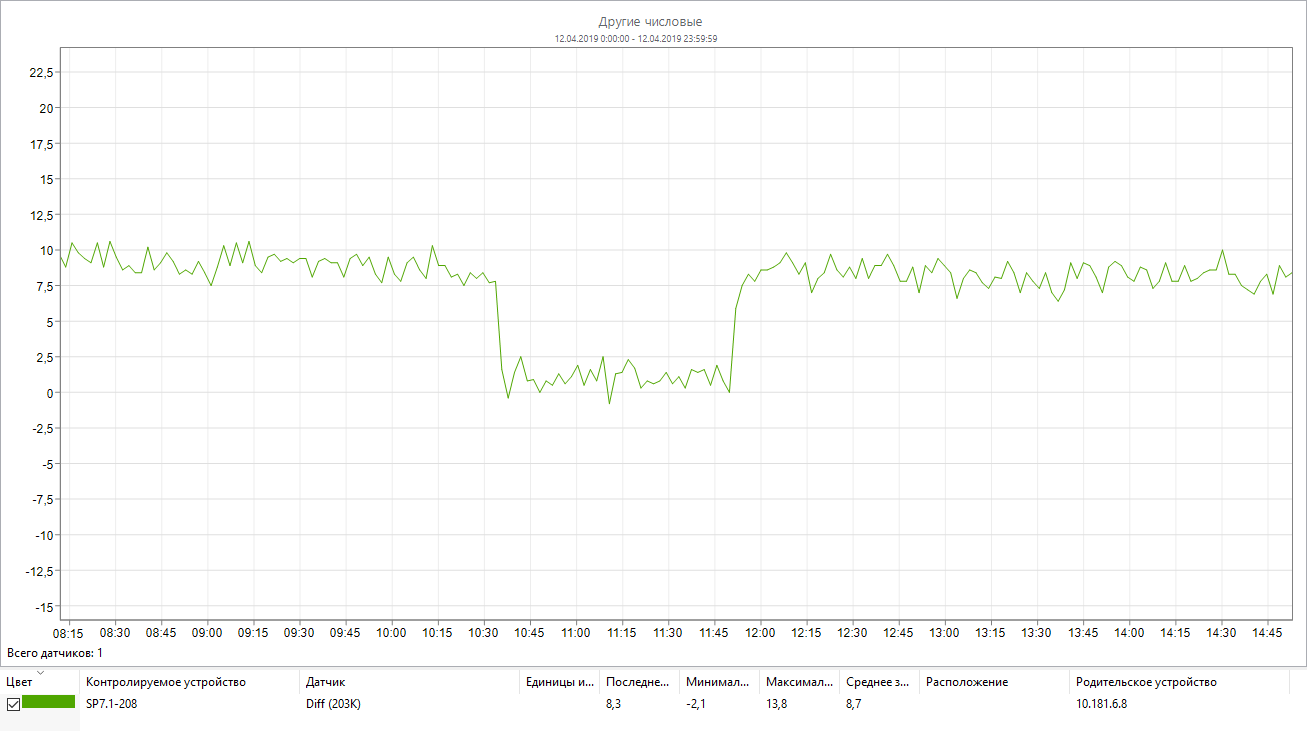

This is the statistics of the manometer readings in the monitoring system:

According to GOST R ISO 14644-4-2002 “Cleanrooms and associated controlled environments”, taken by us as a guideline, “for unobstructed opening of doors and eliminating unintended oncoming air flow due to turbulence, as a rule, the pressure drop between cleanrooms or clean areas with different purity classes should be between 5 and 20 Pa. ”

It is this range that we have taken as the norm in the data center. As soon as a deviation occurs, it is immediately recorded in the system, as shown in the graph below.

A sharp drop in pressure on the chart is an open door to the server room.

If the sensor reads below the setting for more than 5 minutes, it means something with a filter, some kind of accident has occurred, in a word, something extraordinary. Specifically in this graph, the reason is the prolonged opening of the door for the delivery of equipment into the room.

What we got

Firstly , a new level of control and transparency of the data center engineering systems.

Secondly , the control of cleanliness has become even more effective: the system allows you to prevent reduction of backwater and change air filters in advance or eliminate other reasons for its reduction.

Thirdly , all these processes are controlled by mathematically accurate tools. We collect the history of observations in dynamics and have statistics on the real life of the air filters and all emergency situations.

The audit by Management & Operations and our recent visit to European data centers showed that we are pioneers in this direction not only in Russia but also in the EU - not every leader of the data center market in Europe has such solutions.

Of course, this system is not key to the operation of site engineering systems. At the same time, this is an extremely useful addition to the operating service and an excellent illustration of the compliance of our data center with high standards. There are no trifles in our industry.