MIT 3D printer: up to 10 materials per model

MIT has developed a 3D printer that can print ten materials at once. The company wants the device to be able to print fully functional objects, such as printed circuit boards, in the near future.

An article by Mary-Ann Russon from Ibtimes.co.uk translated for you by the Top 3D Shop .

Researchers at the MIT Laboratory of Computer Science and Artificial Intelligence (CSAIL) have made a breakthrough in 3D printing by developing a prototype3D printerthat can use up to 10 different materials at the same time.

At the moment, most3D printerscan print with only one material during one process, many can already with two, and very rare models with three or five. Multimaterial3D printersexisted before - Stratasys launched the world's first full color3D printerwith several materials in January 2014. He was able to print objects made of rubber and plastic, but his problem is the extremely high cost ($ 250,000). Another drawback of this solution is that it still required human intervention in the printing process.

The new 3D printer from MIT - MultiFab is free from these shortcomings. This is an all-in-one system worth $ 7,000, it can quickly print multi-component objects from different materials, and operator intervention in the process is not required.

How does MultiFab work?

During printing, the printer controls the progress of work, for this it uses three-dimensional machine vision.

The data received from the optical sensors allows the 3D printer computer to calibrate the device and correct errors that occur.

During printing, specialized components, such as electronic ones, can be added to the model. The device will continue to print around these components, incorporating them into the final product.

“With MultiFab, we have combined two worlds - traditional manufacturing and 3D printing. We will be able to make a number of new objects, which until recently were impossible to create.

Now 3D printers are mainly used for prototyping, creating injection molds and other types of blanks, but MultiFab will create full-fledged functional objects, combining several materials with different properties, "

Said Javier Ramos, a research engineer with CSAIL and co-author of the research work.

Modern electronics in the future

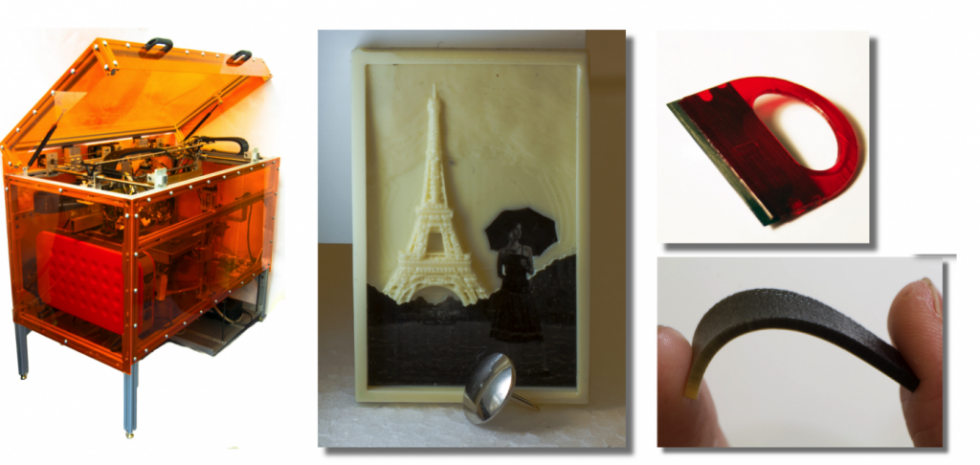

LED lenses that have been printed in 3D using the MIT MultiFab.

At the moment, CSAIL researchers have already succeeded in printing LED lenses, a plastic holder for a metal blade, and smartphone cases that print right around the gadget. The developers believe that MultiFab will find its application in the production of consumer electronics, in medical imaging and in telecommunications.

The next step for researchers will be 3D-printing of objects with built-in motors and actuators. If the finished products can function, this will open up opportunities for 3D printing in the field of advanced electronics, such as the creation of robots.

“Designers and engineers are used to designing using only one material. With the advent of such equipment, the design paradigm itself will change. This will require new hardware and software, and we will have to change the way we, engineers and designers, approach the development process.

Imagine someone who sells electric wine openers, but he doesn’t have $ 7,000 to buy such a printer - he can go to a copy center with a digital model and print a batch of finished products at a reasonable price. My dream is to use my equipment for such purposes ,

”said Ramos.

Share your opinion in the comments.