The answer to "Easel for the microcontroller programmer"

What would catch her? So, okay ... now turn ... the next ... first turn ... stop, here you need to solder the test output for the oscilloscope ... and where did the first board go? What are you? (The following is an untranslatable pun using local idiomatic expressions).

Yes, we stillboil use LUT , dirty LUT.

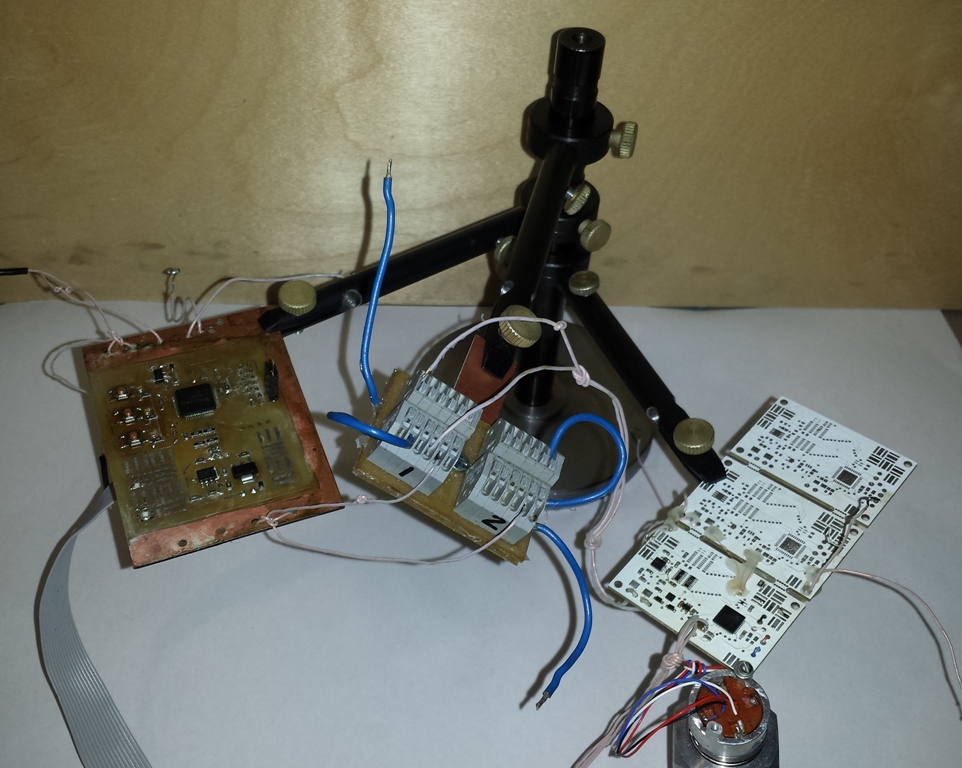

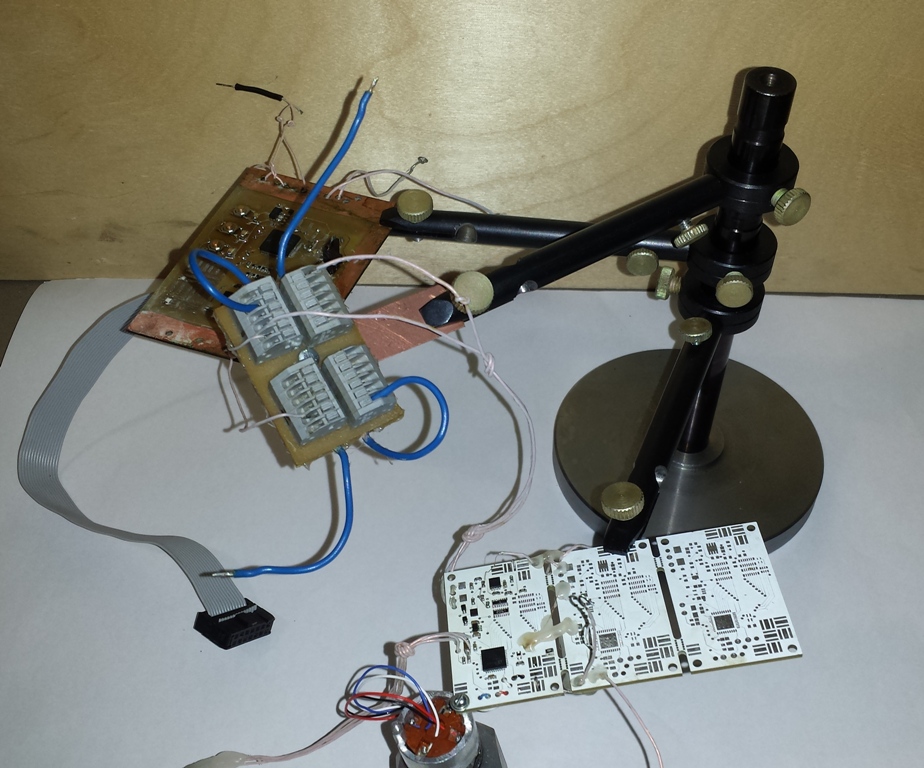

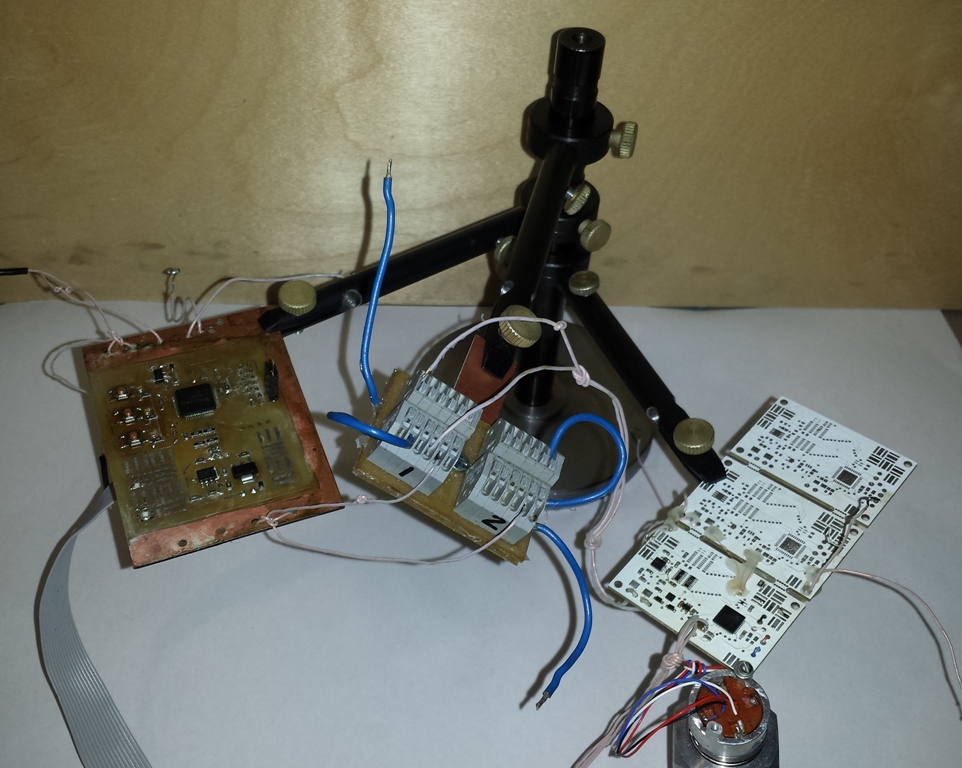

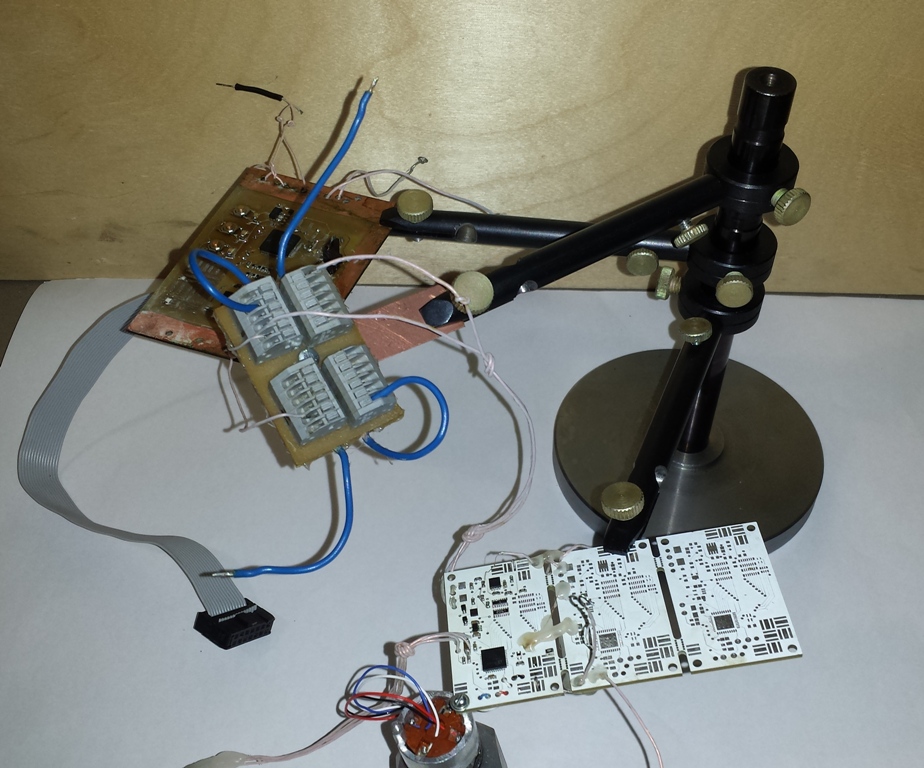

In this post, I summarize a certain result ofmy ordeals of organizing a workplace, namely, brackets for holding electronic circuit boards during soldering and debugging.

Usually, one device is one board. But in my practice, even one board at a certain stage is 2-3 boards. And there is nothing to say about cases when you have to make an interface with a couple of other devices, and they, in turn, are also not always presented with one board.

It still began in his hungry student years. It was necessary to solder, but there were no devices, just as there was no money to buy them.

A flexible holder for a table lamp, a clothespin clamp from the nearest hardware store, “cold welding”, half an hour of time and a three-story mat. After working for 5 minutes, I realized that the design is convenient in principle, but there are several nuances that negate all efforts:

I don’t remember what happened next, but for 2-3 years I didn’t have to touch the soldering iron either at home or at work, and because the device was useless, it was lying around idle, honestly collecting 3 kg of dust per year. I got it just for the sake of the photo.

The question again arose when prospects loomed up on the horizon to pick up the main heating tool of any electrician / electronics engineer / sadist (underline as necessary). At this point, it was decided to allocate 2 tr from hard earned (like, it cost so much then) and buy from Uncle Liao a vise on a hinge. Done. Swivel vise with suction cup paid-sent-received.

This vise has been helping me out for quite some time, and of the available options, in my opinion, it was the best solution. But, again there were nuances:

Vise and at the moment serve faithfully. Again, of the available options for home use, in my opinion this is the best. By the way, one of the pluses, unlike Chinese tripods with a magnifier, is the ability to work with a file or file.

The story continued when, once again, changing my work, I turned from a microcontroller programmer into an electronic engineer (in our village, it didn’t happen like that). The enterprise, although it was seized, but on the remnants of the empire there were many interesting pieces of iron.

It was decided, based on the good old technologies, to make a device that meets our needs, namely:

Fortunately for me, there is an assistant who, without further ado, with healthy enthusiasm, set about translating my ideas into drawings, which were subsequently transferred for implementation to the appropriate department. Comrades from the department, having sighed at the sight of the drawings provided, then turning a finger at the temple about certain points (we are still doing electronics, not metalworking), in turn, also began to carry out the task with healthy enthusiasm.

The result, as expected, turned out to be positive, and within 3 days from the start of use, a second such tripod was made for the second workstation. There is probably only one minus - it is not very convenient to solder boards larger than 50x50 mm.

I can’t post drawings for 2 reasons:

You say: “Yes, where does the DIY?” Yes, the production was carried out by a very good turner and on a metal lathe, and also used electrical discharge machining (not at all a cheap thing). Almost all parts are bent or galvanized. All cogs were machined specially. But honestly, I’ll say - I think that most of these operations can be done manually, or not done at all without any loss in functionality. Instead of unique cogs, it is quite possible to use ordinary galvanization under a hexagon. Burnishing in principle does not affect flight performance. Beautiful, hardened, machined on a turning axis, bushings and rings can be safely changed to "Chinese studs and nuts made of 3 plasticine steel." But will it be worth your attention?

Yes, we still

In this post, I summarize a certain result of

Usually, one device is one board. But in my practice, even one board at a certain stage is 2-3 boards. And there is nothing to say about cases when you have to make an interface with a couple of other devices, and they, in turn, are also not always presented with one board.

It still began in his hungry student years. It was necessary to solder, but there were no devices, just as there was no money to buy them.

Attention! People with an atrophied sense of humor are better off not looking under the spoiler.

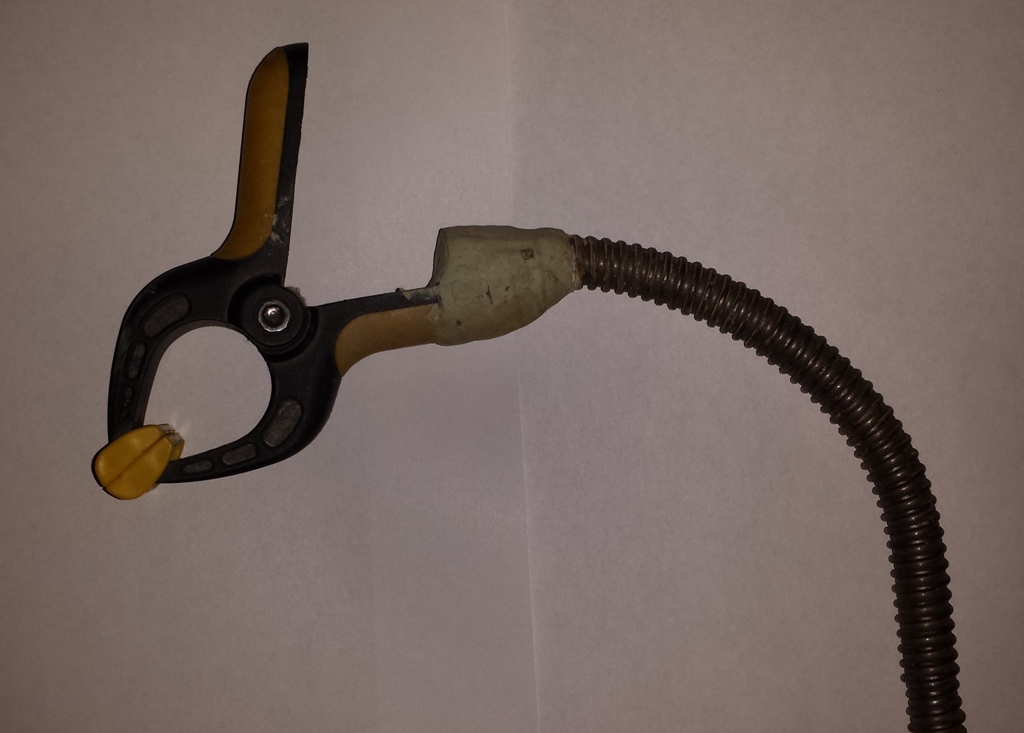

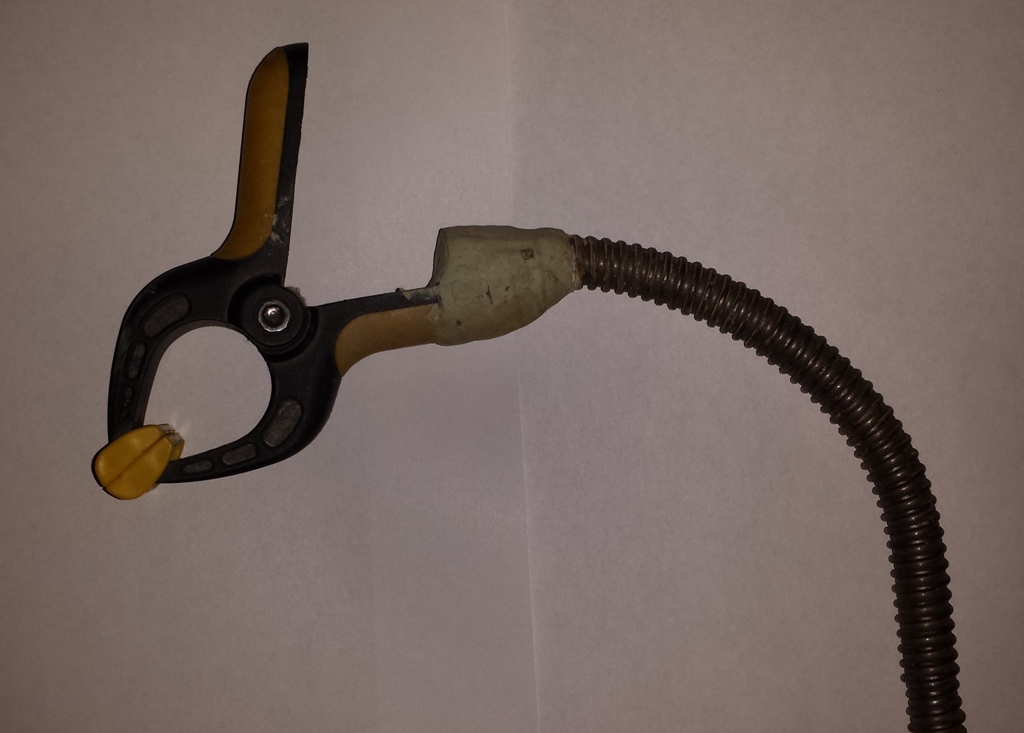

A flexible holder for a table lamp, a clothespin clamp from the nearest hardware store, “cold welding”, half an hour of time and a three-story mat. After working for 5 minutes, I realized that the design is convenient in principle, but there are several nuances that negate all efforts:

- Flexible holder too flexible. When you click on a component or pull it out of the board, the entire structure slowly lowers or rises;

- the plastic clothespin, although it was the smallest available, was still too rough. Do not hold a small board. Also, plastic tends to melt when touched with a soldering iron (who would have thought);

- clothespin one.

I don’t remember what happened next, but for 2-3 years I didn’t have to touch the soldering iron either at home or at work, and because the device was useless, it was lying around idle, honestly collecting 3 kg of dust per year. I got it just for the sake of the photo.

The question again arose when prospects loomed up on the horizon to pick up the main heating tool of any electrician / electronics engineer / sadist (underline as necessary). At this point, it was decided to allocate 2 tr from hard earned (like, it cost so much then) and buy from Uncle Liao a vise on a hinge. Done. Swivel vise with suction cup paid-sent-received.

Such a vice on the Internet Over 9000 !!!

This vise has been helping me out for quite some time, and of the available options, in my opinion, it was the best solution. But, again there were nuances:

- the choice fell on a vice with a suction cup for a reason. Having put a vice deeper on the table, you can put your elbows on your hands, which gives a certain convenience during installation. But the suction cup stubbornly refused to suck for longer than 5 minutes, and if the vice was very tilted, then they simply turned over under their own weight. I don’t know, ski felts do not go ...

- for mounting one board is normal, you can use the force during dismantling, but still the tool is rather rough and you will not pinch a small scarf;

- sizes. They take up a lot of space on the table;

- still only one board.

Vise and at the moment serve faithfully. Again, of the available options for home use, in my opinion this is the best. By the way, one of the pluses, unlike Chinese tripods with a magnifier, is the ability to work with a file or file.

The story continued when, once again, changing my work, I turned from a microcontroller programmer into an electronic engineer (in our village, it didn’t happen like that). The enterprise, although it was seized, but on the remnants of the empire there were many interesting pieces of iron.

Some specialized clamps

It was decided, based on the good old technologies, to make a device that meets our needs, namely:

- satisfy the need to hold several boards at once;

- the ability to fix small boards;

- the ability to gain access to both the upper and lower sides of the board without unnecessary gestures;

- a lot of weight so that during debugging everything suddenly does not start to leave the table under the weight of several wires from the multimeter (s) or the oscilloscope.

- in its production, it is advisable to do exclusively with turning and drilling, since there is no free access to other equipment, and this may delay our small project. (That moment when it is possible to minus for the lathe in DIY).

Fortunately for me, there is an assistant who, without further ado, with healthy enthusiasm, set about translating my ideas into drawings, which were subsequently transferred for implementation to the appropriate department. Comrades from the department, having sighed at the sight of the drawings provided, then turning a finger at the temple about certain points (we are still doing electronics, not metalworking), in turn, also began to carry out the task with healthy enthusiasm.

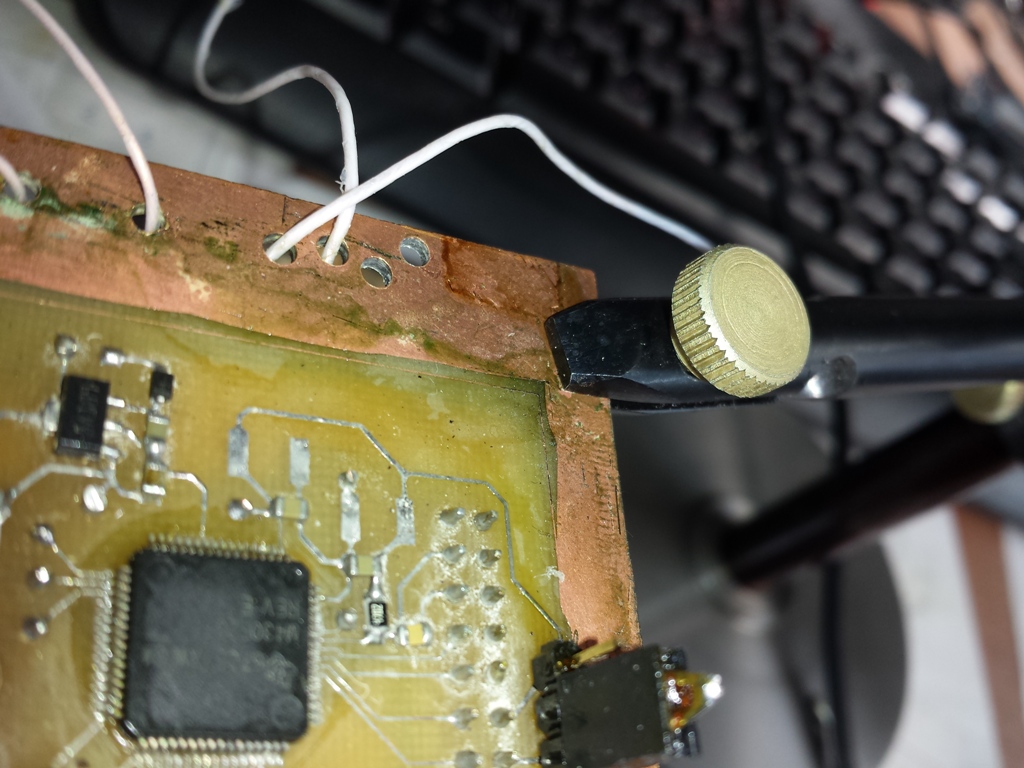

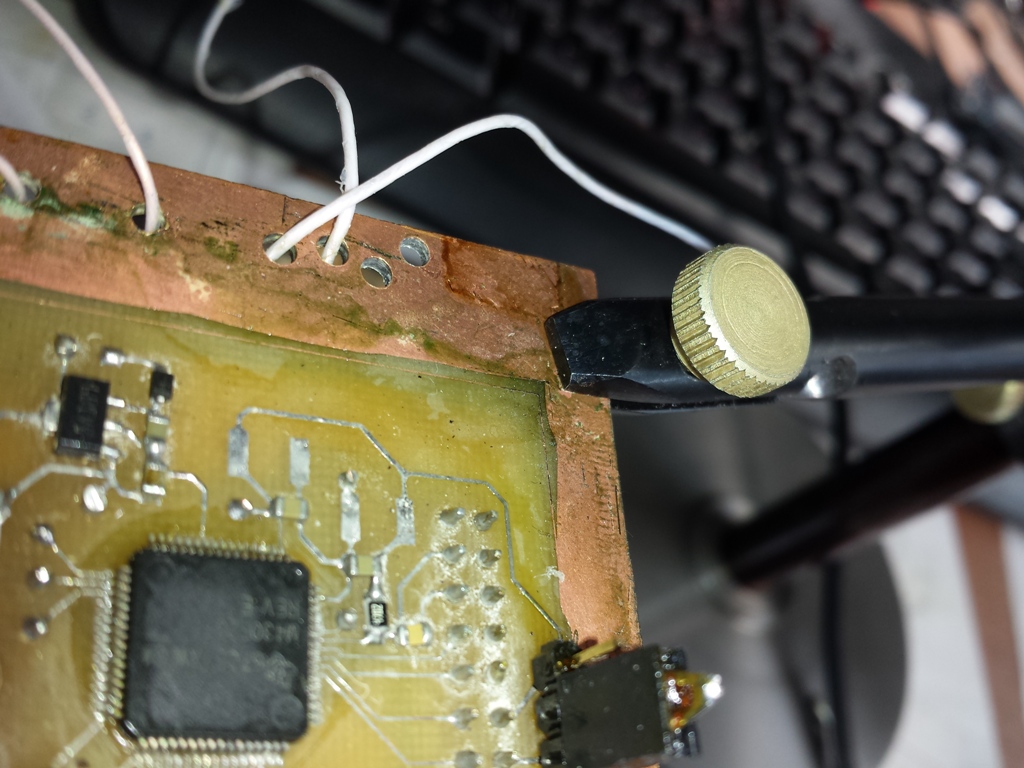

The resulting tripods

The result, as expected, turned out to be positive, and within 3 days from the start of use, a second such tripod was made for the second workstation. There is probably only one minus - it is not very convenient to solder boards larger than 50x50 mm.

I can’t post drawings for 2 reasons:

- in spite of the fact that it was made for me, the drawings do not belong to me;

- honestly, they have no particular value. If someone thinks to implement something like this, he will still have to re-calculate everything for his tasks.

You say: “Yes, where does the DIY?” Yes, the production was carried out by a very good turner and on a metal lathe, and also used electrical discharge machining (not at all a cheap thing). Almost all parts are bent or galvanized. All cogs were machined specially. But honestly, I’ll say - I think that most of these operations can be done manually, or not done at all without any loss in functionality. Instead of unique cogs, it is quite possible to use ordinary galvanization under a hexagon. Burnishing in principle does not affect flight performance. Beautiful, hardened, machined on a turning axis, bushings and rings can be safely changed to "Chinese studs and nuts made of 3 plasticine steel." But will it be worth your attention?