Full-cycle additive manufacturing at an aviation enterprise is a matter of the near future

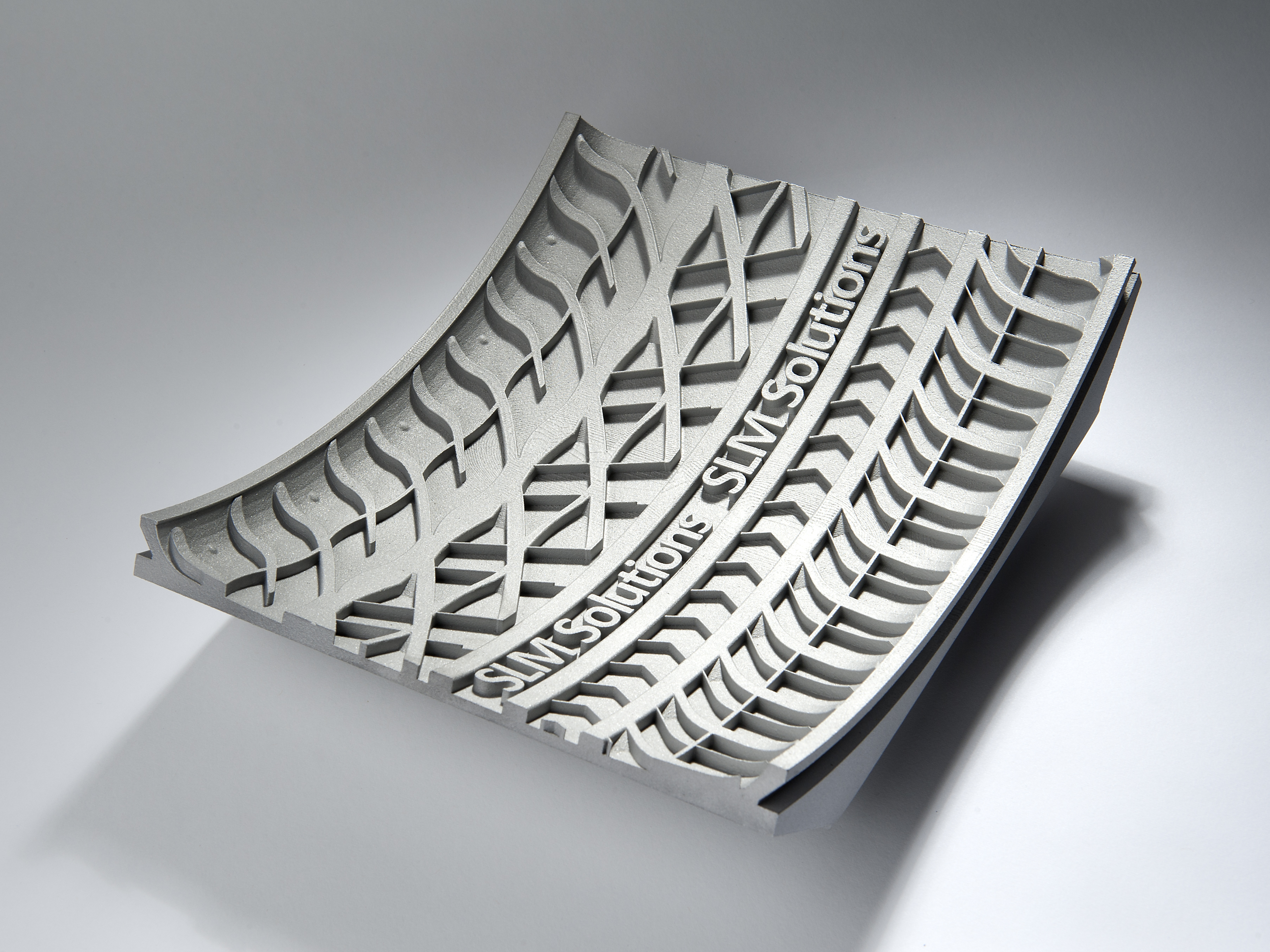

SLM Solutions (Germany) is one of the world's leading manufacturers of industrial 3D printers using selective laser melting technology . In February 2016, the SLM representative office was opened in Moscow. We talked with Pavel Ladnov, a leading technical expert at SLM Solutions RUS. The conversation touched upon the implementation of additive technologies at domestic aerospace enterprises, as well as the solutions offered by SLM Solutions.

- If we are talking about 3D-technologies, what tasks do aerospace enterprises face, what problems are most relevant for them?

- Firstly, this is the problem of certification of the manufacturing process based on additive technologies. Secondly, the lack of experience in working with difficult alloys of titanium and nickel in selective laser melting (SLP). And finally, the lack of powder compositions, alloys of aluminum and magnesium widely used in our country, steels, etc.

- Please tell us about the solutions that SLM Solutions offers.

- Our company presents a wide range of various options and equipment configurations, allowing to most fully satisfy all customer requirements. The SLM 280HL and SLM 500HL models use multi-laser systems with a power of each laser of 700 W - this is interesting just for aviation subjects. This option provides (for example, on the SLM 280HL) an increase in productivity of up to 30 percent on aluminum alloys compared with a similar installation, but with two 400 W lasers. To solve the problems associated with the certification of the manufacturing technology of parts, the company’s equipment is optionally equipped with monitoring systems for working real laser power and systems for monitoring the emission of thermal radiation from the melt pool. It should be noted that the quality control system of the deposited and fused layer and the system for streaming log files of the installation process are included in the basic equipment. SLM Solutions is also constantly working to expand the range of metal powders supplied by the company.

- What are the specifics of the application of 3D technologies in the aerospace industry?

- First of all, this is a strict certification procedure. The quality of a part obtained by selective laser melting is determined by four main factors.

1. The quality of the 3D printer.

It is ensured: by conducting and analyzing test work before the equipment is shipped to the client, and then on the client’s premises after the equipment is installed, and by regulating calibration and maintenance procedures.

2. The quality of the process of building parts.

Provided by: regulation of process parameters and equipment settings.

3. The quality of work with equipment.

It is provided: by regulating procedures for working with equipment and external conditions of the room for equipment operation; level of training of the operators of the additive installation.

4. The quality of the material used.

It is provided by: input control and testing of the material, regulation of storage, transportation, work with the material.

Based on this, one can imagine how laborious the certification process for all four of these parameters can be to obtain a certified part.

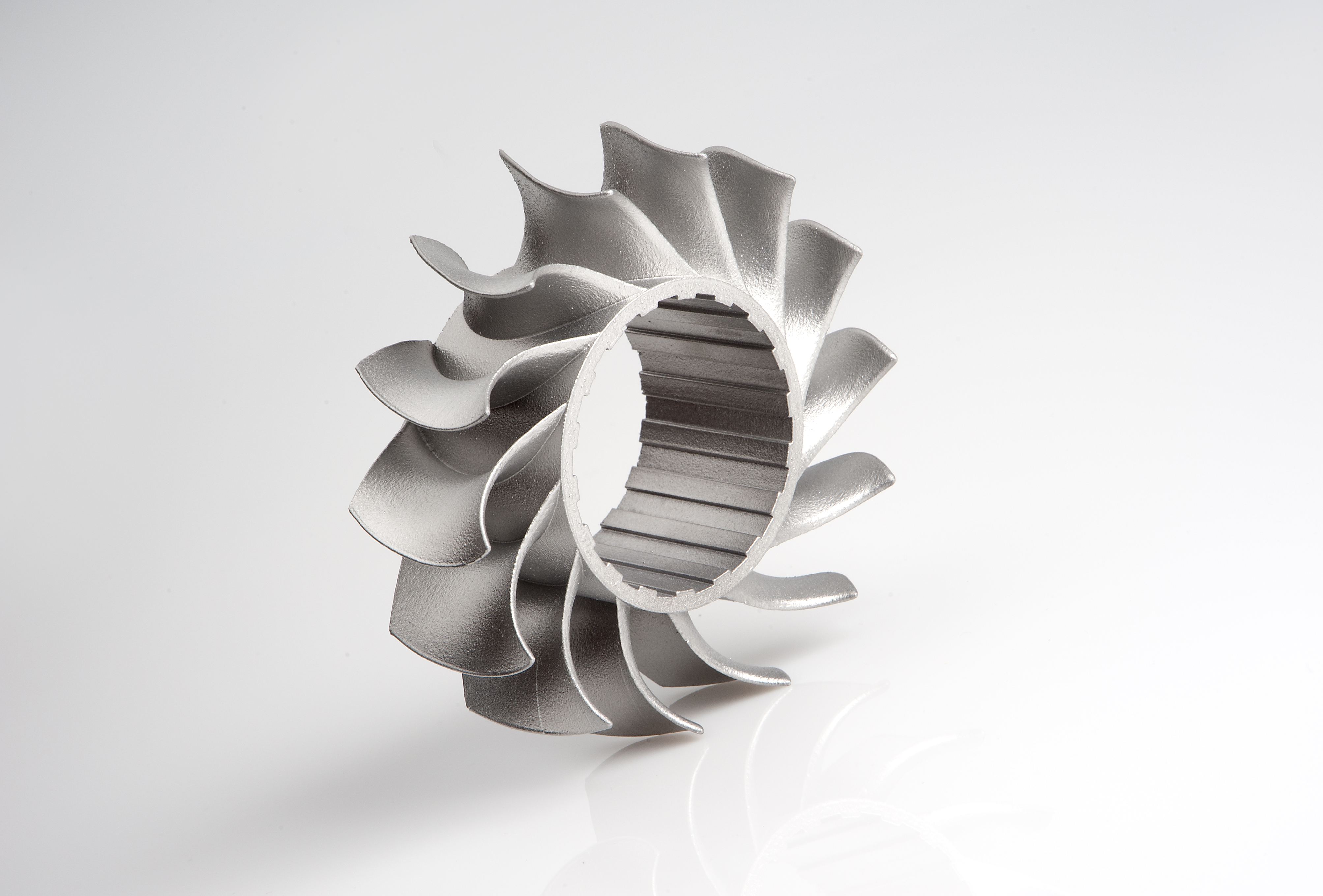

Another important feature of the application of selective laser melting technology in the aerospace sector in particular is the work with technologically difficult materials such as titanium and nickel alloys. These alloys are prone to the formation of residual stresses, leading to warpage of parts and even cracks.

The geometry of aerospace parts is sometimes replete with thin walls, complex complex shapes, cellular structures, while the standard parameters for the material provided by the equipment manufacturer refer to the “average” part, not too large and not too thin. There is an obvious need to pre-work out the parameters of the construction process, not only for the material in general, but also for parts with a characteristic geometry. Failure to understand this feature sometimes leads to confusion for people who believe that a 3D printer should produce a high-quality part by pressing the Start button without any preliminary elaboration of the process.

- At what level is it now possible to use additive technologies in aviation - laboratory tests, manufacturing of single parts, small-scale production or full-fledged additive production in the chain of the general technological process at the enterprise?

- Additive technologies in aviation make it possible to sharply reduce the Buy-to-Fly coefficient, that is, the ratio between the amount of purchased material and the amount of material in the finished part that will “fly”. They also make it possible to achieve previously unattainable functionality of individual parts and components, to produce lightweight and durable parts, thereby increasing the payload of the aircraft. However, as I have already said, serious issues related to certification and ensuring the stability of the production process are still not fully resolved.

SLM Solutions has a large portfolio of customers from the aviation industry. All of them first tested the parts in the laboratory, after which some customers were able to use 3D technology for the manufacture of single and small-scale parts. Additive full-cycle production at an aviation enterprise is a matter for the near future.

- Is SLM equipment the ultimate solution? Or do you need separate software to prepare for printing, for post-processing, etc.? What do you advise customers in this case?

- The equipment of SLM is primarily a tool, a combine, if you like, for solving various production tasks in the field of 3D printing with metals. You can draw an analogy with Photoshop software, which has a huge number of settings and use cases, and each user selects exactly what he needs to solve a specific problem. Yes, definitely SLM equipment is Photoshop in the market for selective laser melting plants.

Depending on the task, the tool can be both the final and intermediate solution. Of course, the problems regarding the design of parts, topological optimizationand generative design, require the use of third-party software to obtain the final source model of the part. Preparation of parts for printing is carried out using the software supplied with the equipment and the post processor, no additional software is required.

Due to the nature of the selective laser melting process, parts made of materials such as nickel, titanium alloys, tool steels may require additional heat treatment or HIP treatment.

The process of selective laser melting cannot be attributed to high-precision processes, and the surface quality of parts is comparable to casting on burned and lost wax patterns. Therefore, structural elements of parts with higher requirements for roughness and flatness of the surface must be subjected to subsequent finishing machining.

- What is SLM Solutions superior to competitors in technical terms?

- The main advantage of SLM Solutions equipment is the highest performance in its class thanks to the patented multi-laser system, the use of 700-watt lasers and the deposition of layers in two directions.

Other advantages include an open system for setting parameters of equipment, ease of maintenance, a powerful post-processor and the availability of control systems for parameters of the construction process with the ability to save data, a wide range of configurations of installations and peripheral equipment.

- What metal powders are used in 3D printing? Can SLM 3D printers use metal powders from other manufacturers?

- SLM Solutions units are adapted to work with almost all materials. The range of metal powders of the company includes not only alloys widely used in the SLP process, such as TiAl6V4, 316L, IN718, AlSi10Mg, but also quite rare in the market of 3D printing services, such as Invar36 with a low coefficient of linear thermal expansion and tin bronzes CuSn10 .

Basically, powders for the SLP process are obtained by gas or plasma atomization methods. An important condition is the spherical shape of the particles and the absence of satellites. From the point of view of operation, the SLP installations impose the most stringent requirements on the fluidity of the powder. To achieve good fluidity allows both the spherical shape of the particles and a certain fractional composition. Basically, powders for the SLP process have a particle size in the range of 10-63 μm and a single-mode distribution.

- What can you say about the quality of powders produced in Russia (if they are already offered on the market)?

- It is difficult for me to judge the quality of Russian powders, since I did not specifically deal with this topic. However, I want to note that we have customers who use domestic powders and, in principle, provide the necessary quality of parts. Sometimes the problem is not so much in the powder as in the correct conduct of work to optimize the parameters of the construction process for a specific material. The key to the ability to use powder in SLM Solutions installations is good powder flowability, and you can work with the rest.

- Let's talk about the prospects for developing in your company new technologies, equipment and materials for solving problems in the aerospace industry.

- First of all, SLM Solutions, as a manufacturer of equipment, seeks to improve the design of installations for SLP, to make them more convenient and productive. Work is underway to improve monitoring systems for the construction process - this is important just for certification of technology in aviation - and to improve peripheral equipment. Another area of work is related to testing the parameters of the SLP process for new groups of alloys - expanding the range of powders used. SLP technology is very flexible and variable, there are many promising areas.

- What else could you share with readers of our blog?

- I would like to say such an important thing. Of course, additive technologies are the future, but do not take them as a panacea, a universal method for manufacturing parts. Journalists sometimes like to greatly exaggerate existing opportunities, but engineers must understand: each method has its limitations in terms of applicability - technological, economic, technical and others.

Selective laser melting, indeed, allows you to look beyond the usual approach to the design of parts, offers certain advantages, but they are realized only when the user of the technology understands the limits of its applicability - by materials, design, and economics of the production process.

3D printing should be taken as another version of the technology for producing products along with mechanical and plastic processing, casting, welding. When choosing options for the production process, carefully weigh the pros and cons.