Top 10 Strangest Things Printed on a 3D Printer

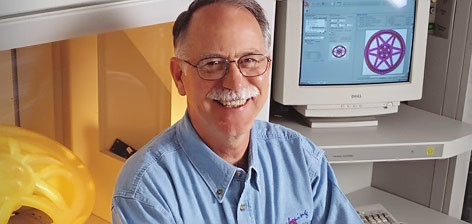

More than 30 years ago in 1983, Chuck 'Hull invented the first STL 3D printer (STL is a technology of stereolithography, when, under the influence, as a rule, UV radiation cures polymer with certain properties layer by layer), after 3 years it founded the company 3D Systems. And although 3D printing technology is the same age as CD players and camcorders, it has not achieved such popularity. However, with the advent of the RepRap project, the alignment of forces has changed, and cheap Chinese 3D printers, albeit FDM and not STL, have brought this technology to the masses in recent years. Now almost everyone has heard about 3D printing, and unusual methods of applying these technologies constantly appear in the news. But the photo below is just the world's first 3D STL printer.

More than 30 years ago in 1983, Chuck 'Hull invented the first STL 3D printer (STL is a technology of stereolithography, when, under the influence, as a rule, UV radiation cures polymer with certain properties layer by layer), after 3 years it founded the company 3D Systems. And although 3D printing technology is the same age as CD players and camcorders, it has not achieved such popularity. However, with the advent of the RepRap project, the alignment of forces has changed, and cheap Chinese 3D printers, albeit FDM and not STL, have brought this technology to the masses in recent years. Now almost everyone has heard about 3D printing, and unusual methods of applying these technologies constantly appear in the news. But the photo below is just the world's first 3D STL printer.

So, I present a selection of ten of the strangest things that can be printed on a 3D printer.

1. Angelic forms

Japan is the birthplace of all sorts of unusual gadgets, customs and trends. So in 3D printing here they managed to excel. The Japanese company Fasotec , or rather its unit Biotexture, offers an unusual service. For future parents, not just a photograph or video of their fetus is available, but a whole printed 3D model.

It sounds a little unusual, visually it looks even more extraordinary. Like a beetle frozen in amber, an embryo is located in a transparent polymer crystal in its natural position. It’s good that the colors are selected just contrasting and not the same as they are in their natural form, otherwise it would look generally creepy. This all became possible thanks to one of the main activities of fasotec - Magnetic Resonance Scanning of the Body. In principle, the company “ate the dog” on such things, they have long been engaged in scanning various organs and printing them, which allows surgeons to prepare well for the upcoming operations.

Well, here it’s like a “by-product”, although it has caused quite a bit of noise and attracted additional attention to the company. Is it a joke, the germ in the crystal. Such crystals with an embryo inside are called “Shapes of Angel” (angel shapes) and cost not so cheap about 100,000 yen, this is about $ 870 dollars (as of 02/11/16), the price excluding the flight to Japan, of course. The size of this crystal is approximately 90x60x40mm, and it is issued to the customer in a cute beige box with pink silk inside.

It is worth buying one to shock your future children when they grow up.

2. Tapkaburger

Oh gods, he eats a sneaker! That's probably what people think when they first see a person absorbing a Shoe Burger. But here, in fact, there is nothing unusual. It’s just a burger with a bun in the form of your sneaker or shoes.

Here several advanced technologies came together: 3D scanning, 3D printing and silicone casting. That's basically the whole description of the process.

Put your shoe on the table of the 3D scanner, create a digital copy. Print it on a 3D printer and make the reverse form of heat-resistant food-grade silicone. Now it remains only to fill it with dough and send it to the oven.

In my opinion this is a great way to surprise your friends who come to visit you. Just feed them with slippers.

3. Nanosculptures

We live in an amazing time, we are surrounded by a huge number of wonderful things that you can see and often even touch. But Jonty Hurwitz (Jonty Hurwitz) creates sculptures that can not be touched, but even see them without a microscope will not work.

All this thanks to a special 3D printer that can create such tiny objects.

Who complained about the layering of the press? There will be no problems with layering with such a printer, however, in order to create some kind of object more or less visible to the human eye, you will have to wait a very long time.

Such nanosculptures appeared thanks to the technology of the Karlsruhe Institute of Technology , which are successfully used at the Weizmann Institute of Science. A similar printing method is called multiphoton lithography, which is based on the two-photon absorption phenomenon.

So, at the junction of advanced technologies and art, something new is created, now the whole museum can easily be carried with you in your pocket.

4. Weapons

Printed weapons on a 3D printer have long been known. When people find out that you have a similar printer, the first question is, can you print a gun on it? All thanks to the world famous liberal. Wow, how did he make a noise on the net ... Some people even got real criminal cases for his production at home, for example: ... Although in my opinion than using such a gun, it’s easier to cut a spear from any suitable stick, it will be more effective. Moreover, when fired there is a big chance that the barrel can simply break.

But inquiring minds do not stand still, after the liberal a multiply-charged revolver was born.

It looks good, it’s already becoming more interesting, right? Although we are not talking about the classic revolver, the design is similar to barrelless weapons, when the bullet itself is the barrel. There is something in between - the drum itself appears in the rhodium of the barrel. It can be a capacity of 6 or 8 bullets. The bullets are again from the "small things" and fly at subsonic speeds.

The bullet holes must be reinforced with metal tubes, which by the way will act as a barrel. And in the case of an 8-charging drum, it is also necessary to strengthen the drum itself with metal elements.

Or, for example, from a fresh, already semi-automatic Shuty MP-1 pistol. Now this is serious, although the caliber is still small.

There was an article about him recently at Geektimes: Shuty MP-1

But the crown of a 3D-printed weapon (made of plastic) can still be recognized as RailGun. And although there is not the most powerful shot and it does not break through the walls, but this weapon looks very formidable.

5. Human organs or their substitutes

While some people are printing weapons of destruction, others are thinking about how to restore the human body, again using 3D printing. For example, metal printing using SLS or SLM technology (selective laser sintering or selective laser fusion) has long been known, often, if the budget allows, prostheses or missing parts of bones are created.

But science does not stand still and it is already becoming realistically print not only metal structures for the human body, but also the basis of organs that will not be torn away by the human body.

In some cases, plastic is also used. Plastic also does not stand still and in some countries fillings and dentures are tested, which destroy bacteria and prevent caries from developing again.

It remains to wait a little longer for science fiction films where people improve themselves with the help of technology become a reality.

6. Glass vases

Glass. Very interesting stuff. On the one hand, it’s just sand in a large crystal, and on the other, it’s not so easy to work with this material. Creating some complex shapes from glass is all the more difficult. But what if you try to print with glass on a 3D printer?

Apparently, they reasoned at MIT's Mediated Matter Group, the result of their research was perhaps the only one of its kind 3D printer that prints with glass.

True, there are a number of limitations of this technology, such as print speed and layer thickness.

In addition, the structures nevertheless turn out to be layered, which imposes a certain kind of restriction on the use of finished products. So far, the ideal product obtained using such technology is a vase.

A beautiful vase that gives an interesting diffused light, if you shine a light into it from above.

7. Bioprinting or what did you hear about Bi-code?

Various types of art have always been considered by some people to be amazing and others to be strange. Now I’ll talk about really strange, hmm ... probably forms. I don’t know which category it

belongs :) This is the so-called bioprinting. Print objects pori using bees. That's where the fantasy can be played out, I draw unthinkable machines using bees. But no, everything is much simpler. Biologist Jennifer Berry, once looking at wild hives, thought that it looked good, and it would be interesting to control the creation of forms of hives.

As a result, after several attempts, she created a kind of bioprinter-artificial hive, in which bees live and create honeycombs under her control.

The technology is simple - you need to create some form that limits the external borders of the created model,

And it is also necessary to set the growth direction of the honeycomb from a special material.

All this is placed in a transparent box, in which a certain microclimate is maintained and there is a special valve that blocks access to bees in the hive after they complete the creation of the object. I wonder how many finished paintings Jennifer sold? Although she certainly drew attention to her person.

8. Giant sculptures

While some print nanosculptures, others create gigantic art objects on ordinary FDM printers. So, for example, the famous artist Hong-Ji Peng from Taipei (Taiwan) realized a powerful art project in the Museum of Fine Arts - an ocean liner supposedly twisted by the forces of nature.

The creation of this exhibit required a total of 42,000 hours of work. Printing was carried out by thirty-two FDM printers, 6000 parts were printed with a total weight of 500 kilograms. And the length of the liner turned out to be 8 meters.

With his project, Pang wants to remind mankind of its powerlessness in front of uncontrolled natural forces, sometimes leading to terrible disasters.

9. Cars

One of the most grateful industries for 3D printing is perhaps automotive. In addition to prototyping and prototyping, the automotive industry is actively testing new types of materials in automobile manufacturing and new methods for their production.

For example, FORD Corporation, which owns as many as five centers of three-dimensional printing, producing hundreds of parts per day. Printers in these centers print a wide range of materials: from silicates to nylon, and even sand. One of the company's favorite examples when it comes to 3D printing is the engine intake manifold.

But these are all particulars. Of interest, in the context of this article, are the projects of cars entirely or mostly printed on 3D printers.

A recent example of a high-tech car created using 3D printing technology is the Blade supercar from Divergent Microfactories.

Blade is a frame structure consisting of carbon rods and special aluminum nodal elements. According to the creators of Blade, this not only saves material, but also facilitates the car by 90% compared to traditional designs. Blade is equipped with a 700-hp diesel engine powered by gasoline or natural gas. Thanks to the powerful engine and lightweight body, the car can accelerate from 0 to 100 km / h in 2.2 seconds.

10. Food

I recall science fiction films and stories where special food printers print any food with any taste to order almost from the air. This probably sounds fantastic, and in practice it is not yet applicable. However, some imitation of such devices already exists. The strangest thing printed on a 3D printer at number 10 is the food.

The strange thing is that this is only shaping with the help of a 3D printer, there is practically no question of any changes in the properties of materials or creation.

I stuffed the minced meat in a tube and squeeze it according to the program into the desired shape, then into the oven.

Dressed the dough - squeezed out the base for pizza or tartlets. It is more likely an assistant for the cook, when it is difficult to squeeze the drawing with his hands. The machine will do this to the nearest hundredth of a millimeter.

Although artistic value is still present here. With due imagination and a little skill, you can create masterpieces of culinary art.

Conclusion

Thanks to Chinese stores, even with a growing currency, it has now become possible to purchase a home FDM 3D printer for little money. For example, one of the most popular printer assembly kits: Sunhokey Prusa i3 ( * ), which was bought 1748 times only from this seller. I personally bought this kit last fall. Then it cost me a little cheaper than 17 000 rub. Now on aliexpress it also costs about the same money. For half a year of owning this printer, I did not identify any particularly critical places, it worked for me almost immediately after assembly.

That's all, with you there was a simple service for choosing complex Dronk.Ru equipment . Don’t forget to subscribe to our blog and YouTube channel., there will be many more interesting things.

p.s.* — вы можете вернуть до 5% стоимости покупки, приобретая товар по этим ссылкам.

Подробнее: dronk.ru/cashback

Другие наши публикации:

Обзор мощного планшета Chuwi Hi10 на полноценной Win10 за $180

8 приспособлений для съемки видео на смартфон

Классы квадрокоптеров – какие бывают и для чего используются

Видеообзор Walkera Runner 250 — полет над каньоном

Наши маленькие радости или чем бюджетно порадовать себя на 23 февраля?

Компания Xiaomi. Дешевле без ущерба к качеству уже не бывает

Chuwi Ilife V5 — робот-пылесос за 99$ или как превратить ежедневную уборку в развлечение

Обзор граверного лазера NEJE или перспективная бизнес модель