Ultraviolet and polymer: another way to use Bondik glue in everyday life (+ video)

Without glue, a rugged person in no way. After the impact, the case of the beloved telephone will crack, then the decorative element will fall off the furniture ... And if the family has small children, then broken toys are most often repaired with glue!

But the glues are all different and give different results. I always liked the epoxy glue, keeps it dead. But it has two drawbacks: it needs to be bred and it dries for a long time. And if it dries for a long time, then it is not always possible to glue complex figures, it is difficult to fix them until the glue sets. And to hold the glued parts with your hands for 3-4 hours is still a pleasure. I immediately noticed Bondik glue when I saw it.

Brand glue. Made in Canada and, as the manufacturer claims, is completely safe. You can even glue surfaces in contact with food (although if such surfaces are heated to 65 ° C and above, glue should not be used - high temperature provokes the release of harmful substances). It is elegantly packed, and if you want to present it as a gift, then this will be a very good choice.

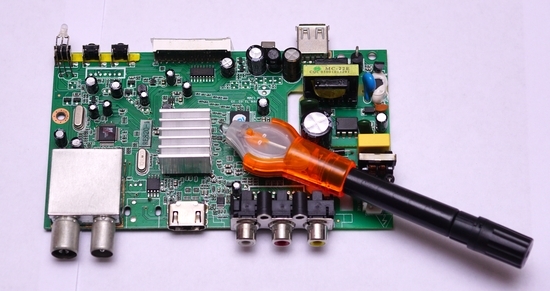

The glue is immediately ready for use, and sets in 4 seconds after you shine on it with the ultraviolet LED included in the kit. Bondik is a liquid polymer. Accordingly, after curing, it turns out the polymer, which is quite strong, and well fixes the bonded parts.

When working with small parts, it is very convenient that the tube nose is thin, and it is possible to apply a small amount of glue exactly to the place where you need to.

And one more feature. Considering that the glue quickly hardens, it can be applied in layers (applied - hardened), thereby filling rather complicated cavities or vice versa, modeling volumetric details, which is simply impossible to do with other glues I know!

Thus, Bondik glue confidently took its rightful place in my home workshop! What I wish you too!