The new manufacturing process has reduced the cost of Li-Ion batteries by half

Researchers at the Massachusetts Institute of Technology and 24M have developed an improved process for the production of new design lithium-ion batteries. According to the calculations of engineers, it at least halves the cost of batteries by simplifying the process itself and reducing the amount of necessary materials, while improving the technical characteristics of batteries.

Li-ion batteries are the most expensive electric vehicle part. Only due to this “hack” the retail price of the car will significantly decrease.

“We reviewed the entire process,” saysProfessor Yet-Ming Chiang, co-founder of 24M (previously also co-founder of battery manufacturer A123). The current battery manufacturing process, he says, hasn't changed much for two decades since the invention of the technology. It is inefficient and uses more stages than required.

By 2020, according to Chan, 24M will be able to produce batteries for less than $ 100 per kilowatt-hour. According to experts, this is precisely the price that represents the price threshold for the mass distribution of electric vehicles. The Tesla Gigafactory 1 megafactory currently under construction is also hoping to reach such a cost by 2017 due to mass production.

Currently estimatedThe cost of Li-Ion batteries is from $ 300 to $ 500 per kilowatt hour.

Semi-solid batteries

The new process technology is a hybrid model between a conventional solid battery and the so-called “ flow battery”, in which suspensions of tiny particles in a liquid pumped into various battery compartments play the role of electrodes. Actually, such a battery design was invented by Professor Chan himself and his colleagues five years ago.

In option 24M, although the electrode material is not fluid, it still consists of a similar “semi-solid” colloidal suspension. Actually, they called it a "semi-solid" battery.

This approach greatly simplifies the production of batteries, and also adds flexibility and strength to them. In the scientific work that the professor published in the journal "Journal of Power Sources" ( doi: 10.1016 / j.jpowsour.2015.06.023), it is said that the new design is suitable for batteries with both low energy density and high energy density, as in Li-Ion batteries.

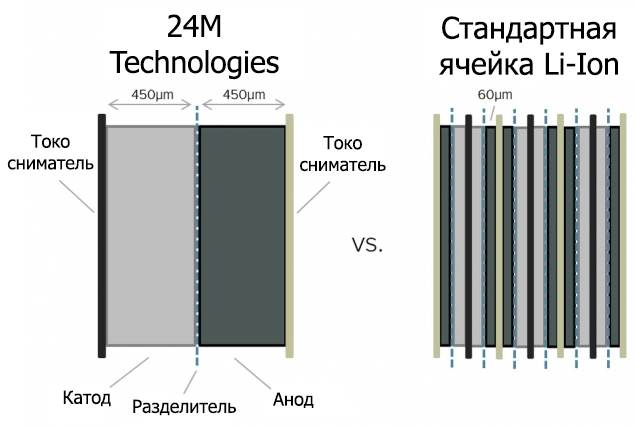

The standard process technology provides for the layered application of liquid on the rolls of the substrate. Each coat must dry before applying the next. The new method does not require any drying at all. Using fewer electrodes with less thickness, it reduces by 80% the number of layers required in the battery, as well as the amount of non-working material inside the battery.

If particles in suspension serve as electrodes, then charged particles need to travel a shorter distance — a property known as “tortuosity”, which reduces the amount of material needed for the electrodes.

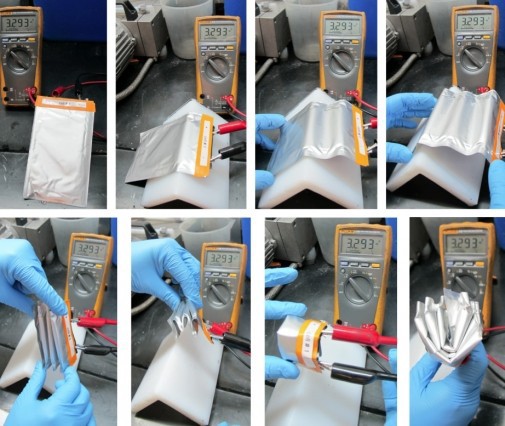

The illustration shows that new batteries can be bent and folded, this does not affect their properties.

24M has already manufactured about 10,000 batteries for testing at the pilot plant. The company received eight patents, and another 75 patent applications are pending. Given the $ 50 million investment received from venture capital firms plus a grant from the US Department of Energy, it becomes clear that the business here is serious.

Initially, it was supposed to use batteries as backup power sources in alternative energy, but now Professor Chan and colleagues decided that the new batteries are quite suitable for electric vehicles.

Importantly, the new manufacturing process allows a small factory to achieve the same cost of production as a huge factory. An increase in production does not produce a noticeable economic effect. So the economic prospects of the Tesla Motors Gigafactory are getting a little more hazy. However, Ilon Mask will not be offended if Li-Ion batteries become cheaper several times without his help.