Why do I need a thermo-acoustic generator?

Fig. 1 Estimated appearance of a home thermo-acoustic gas generator

In one of the previous articles, I talked about developing a thermo-acoustic generator: "Creating and first launching a traveling-wave thermo-acoustic engine . " In this article I want to tell more about the possible applications of this generator and how to integrate it into the existing power grid.

One of the recent global trends is decentralization. An increasing number of people want to be as independent as possible from large organizations. This manifests itself, for example, in the form of a desire to have its own micro factory in the form of a 3D printer, in the form of a desire to produce its own money, such as cryptocurrencies, or in the form of a desire to have its own media, in the form of a channel on YouTube. Energy, too, has long been headed for decentralization. An increasing number of people want to have their own source of electrical and thermal energy.

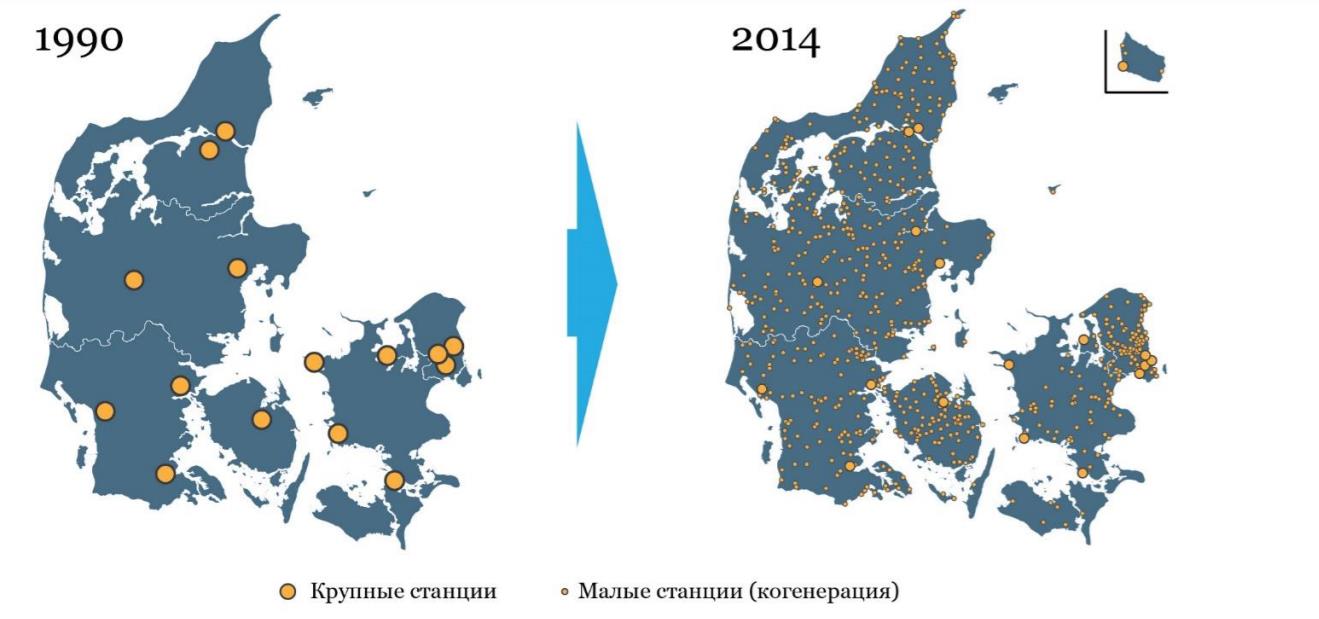

Fig. 2. Illustration of energy decentralization in Denmark based on distributed cogeneration. Source: Danish Energy Agency

For example, energy decentralization is very active in Denmark (Fig. 2).

What are the benefits of energy decentralization?

In addition to increasing the independence and independence of each individual during decentralization, the advantages are that:

- A micro CHP is always much closer to the consumer than a large CHP. Thus, the losses of electric and thermal energy practically disappear when transmitted by wires and heating mains, respectively.

Fig. 3. Micro CHP Senertec Dachs F5.5 on an internal combustion engine with a capacity of 5.5 kW

- It is possible to build houses and businesses in places where it was too expensive or impossible to supply energy at all. For example, you liked some place or the beauty of the landscape, but it is not possible to bring electricity there. In this case, the only way to power a house with energy is to generate electrical and heat energy in place, that is, in the house itself.

Fig. 4. Private house at a distance from civilization

- Distributed generation of energy increases the stability of the energy system to various accidents and disasters. In the event of a disaster at a large CHP plant, with decentralized generation, the number of people cut off from the power supply is reduced.

Fig. 5. Accident at the Fukushima power station

- Distributed generation has great flexibility and adaptability in case of sharp, uneven changes in the area of energy consumption. Thanks to decentralization, it becomes possible to combine multiple energy sources into a single intelligent network called Micro Grid, which aligns and optimizes energy production and consumption.

Fig. 6. Schematic representation of the Micro Grid - an intelligent energy network that optimizes energy production and consumption

- In countries where it is legally allowed to sell surplus electricity generated into a common network, you can earn money using micro CHP. The most common is this type of earnings at the moment in sunny areas, in which, having fixed solar panels on the roof of your house, you can return the cost of the panels for several years selling electricity and then make a profit from them.

Fig. 7. Solar power plant on the roof of the house

- Then, the prospect of micro CHP is that when the resource of existing large power plants comes to an end, then there is a dilemma: to build a new large power plant or a lot of small ones? Recently, the choice is increasingly stopping at creating a network of medium, mini and micro CHP, instead of a large one that failed.

Restrictions on energy decentralization

Energy decentralization has many advantages. At the same time, it cannot be said that one must necessarily strive for the case of the greatest possible decentralization. That is, to the case when in each private, in each multi-storey building, in each enterprise and in each building its own thermal power plant is installed. In places of dense accumulation of energy consumers, a large CHP plant will outperform a group of micro CHPs due to lower energy generation costs associated with more optimized maintenance processes, less complexity and material consumption.

Fig. 8. North-Western CHP

However, there are places with low density of consumer clusters and places in which the construction of large CHP is either impossible or unreasonable. It is in such places that micro CHPs gradually occupy the market and crowd out large CHP plants. Along with micro-CHP, there are also alternative energy sources, such as solar and wind power plants, which are also focused on not densely populated and hard-to-reach areas of the planet;

Thus, it can be said that the decentralization of energy production using micro-CHP is most promising in not densely populated areas with relatively low solar activity and with relatively little wind force or unstable wind.

The optimal zone for the use of micro CHP in Russia

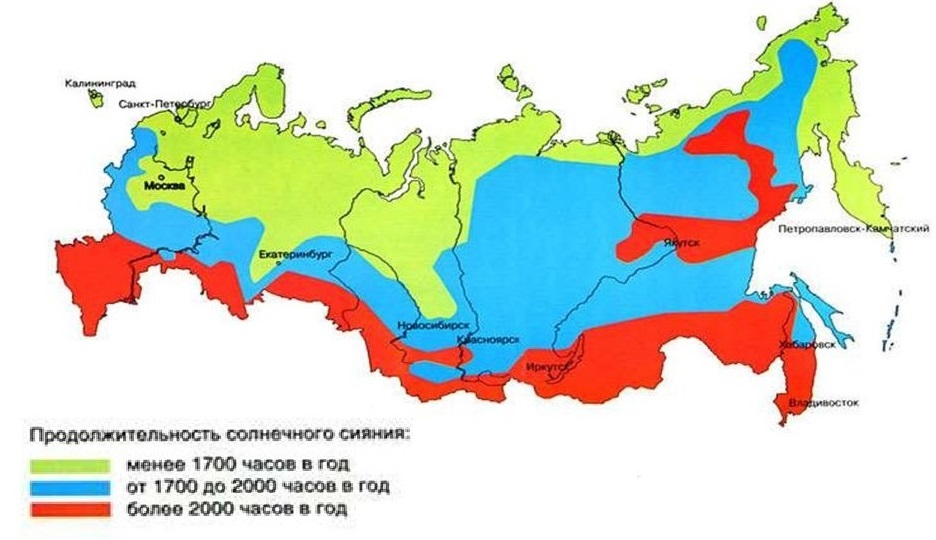

Fig. 9. Map of energy production in Russia.

So what are the sizes of the territory optimal for the use of micro-CHP and how many people live on it? For example, take Russia. About 13% of the population, that is, 19.1 million people, are in the zone not covered by centralized power supply (for 2018). Only a third of the country's territory is covered by centralized power supply.

Fig. 10. Map of solar insolation in Russia

Fig. 11. Map of wind activity in Russia

If you look at the maps of solar activity and wind energy, you can see that the majority of users in the European part of Russia who are not connected to the centralized power supply are in an area with low solar and wind activity. Thus, they are in the zone optimal for micro-CHP.

Currently, in the vast majority of cases, micro-CHPs based on internal combustion engines are used in this region, or a combination generator on the internal combustion engine and a heating boiler are used.

Fig. 12. Mini-CHP on liquefied and natural gas in the town of Klin, Moscow Region

. Capstone microturbine gas generator sets also became widespread in Russia.

Fig. 13. Capstone microgenerators

What are the problems of currently existing micro CHP plants?

The main problems of the existing actively operated micro-CHP are:

- small interval between maintenance, low reliability.

Fig. 14. Repair of a diesel generator

Diesel and gas turbine generators require maintenance at best once a year. This increases the cost of power generation, creates unnecessary organizational work for the owners of such an installation, and during maintenance, the installation naturally has to be stopped for a certain time, which creates problems for consumers.

- Diesel and gas turbine installations do not have the ability to use all types of combustible fuels (liquid, gaseous, solid fuel), and there is also no possibility to use alternative sources of thermal energy (solar, geothermal, waste heat).

Fig. 15. Possible types of thermal energy for micro CHP. From left to right: waste heat of the enterprise, geothermal energy, solar energy, energy of combustible fuels.

Not all consumers have an optimal source of thermal energy for micro CHP - this is diesel fuel or natural gas. It is much cheaper to use other sources of heat energy. For example, in an enterprise in which thermal energy is discharged into the atmosphere, it is possible to save some of this energy by generating electricity at a micro CHP plant with its help. Or in areas with geothermal sources (for example, the Kamchatka Territory) to use the thermal energy of the earth’s interior. In areas with high solar activity, it is possible to use solar energy for heating or jointly solar energy and the energy of burning combustible fuel.

Thus, the use of diesel and gas turbine generators only combustible fuels, is their obvious drawback.

- High initial price of micro CHP. Due to the high price, many people refuse to purchase the installation, since at least the use of the installation will become cheaper in several years than connecting to the power grid, people are not able to manage the price of a micro CHP immediately.

Problem solving

The first two above mentioned problems with a low interval between those. service and omnivorous decide installations based on Stirling engines.

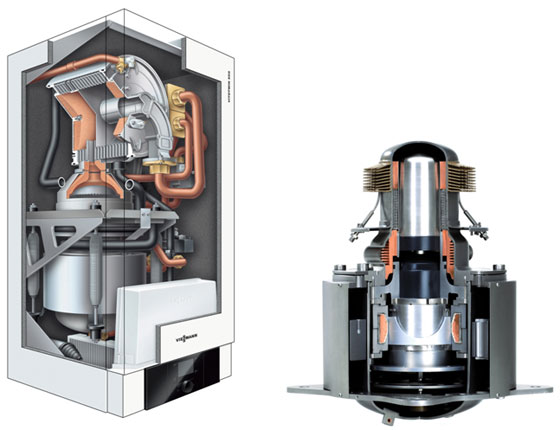

Fig. 16. Micro-CHP Viessmann Vitotwin 300-W

Another solution to the first two problems is installations based on steam microturbines, that is, installations operating according to the Rankine cycle.

As an example of such a plant, developed in Russia, one can cite a micro-energy complex based on a wet-steam microturbine, created by the Donskie Tekhni scientific and production enterprise.

Fig. 17. IEC “Donskie tekhnologii” with an electric power of 5 kW.

Despite all the advantages of these installations as compared with installations on internal combustion engines and gas turbine engines, they have not yet gained great popularity due to higher initial cost, difficulty of repair or unscheduled maintenance ( lack of skilled workers capable of making unscheduled repairs) and because of the long habituation of people to the new technology.

Thermoacoustic Generator

As well as installations on the Stirling engine and on the steam-turbine cycle solve problems with a low interval between those. maintenance and lack of omnivorousity in the choice of fuel, thermo-acoustic generator similarly solves these problems. Accordingly, in order to take a place on the market, a thermo-acoustic generator must have an initial cost lower than that of these plants, and preferably lower than that of diesel and gas turbines. Consider, due to which in a thermoacoustic generator problems are solved with those. service and omnivorous, and whether it is possible to solve the problem with a high initial price.

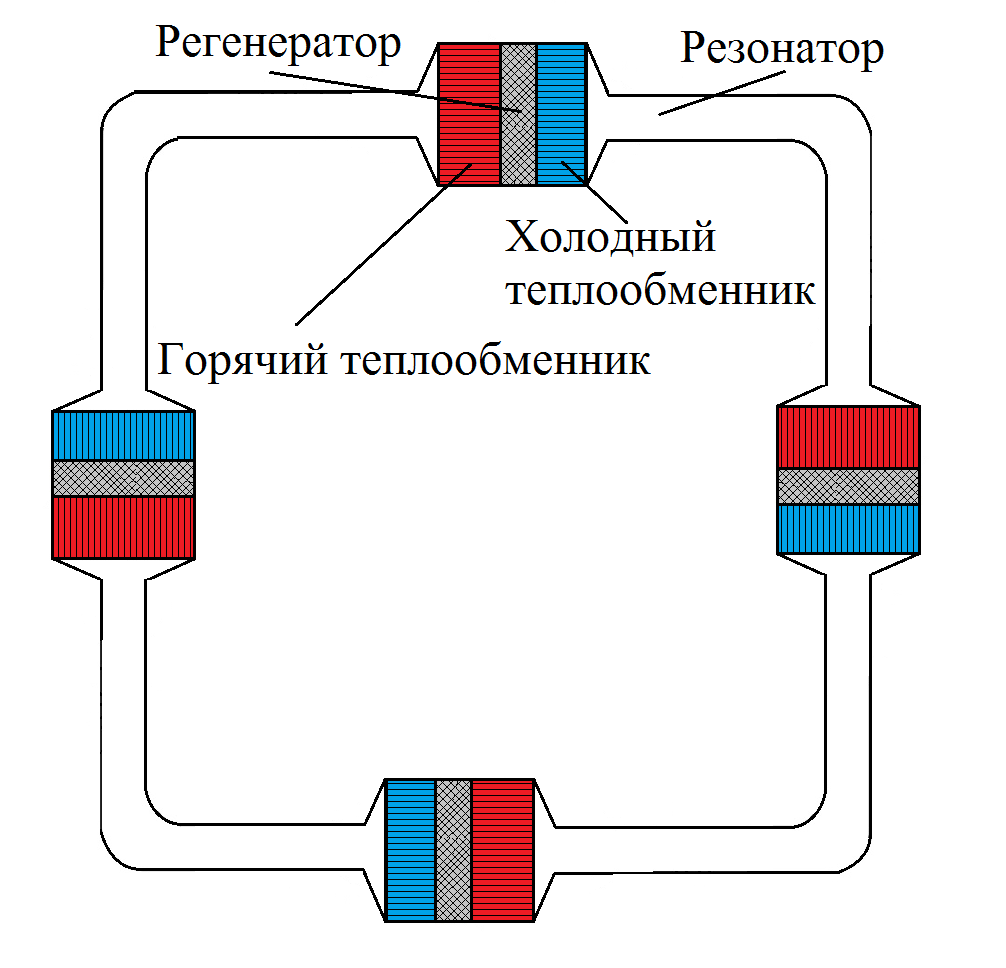

Let me remind you, for those who have not read the previous articles “1 article” , “2 article” , that the thermo-acoustic engine developed by me looks schematically like this:

Fig. 18. Scheme of a four-stage traveling wave engine

The system consisting of a resonator and heat exchangers generates acoustic energy under the influence of thermal energy. That is, in the presence of a certain temperature difference between the heat exchangers, a traveling acoustic wave arises in the resonator.

Thermoacoustic engine in this form is extremely high resource, as it does not contain any moving parts. But to generate electricity, additional turbogenerators are needed, which must first convert acoustic energy into mechanical energy of rotation of the rotor of the turbogenerators, and then into electric energy. Thus, it is expected that the maximum interval between those. the maintenance in this part will be limited by the need to service the turbogenerators and, last but not least, the engine itself.

That is, it turns out on the one hand everything is just like a steam turbine plant. However, a turbo-generator in a thermo-acoustic engine operates at much lower temperatures (about 40 degrees Celsius) than in a steam-turbine cycle, where the temperature of the turbine reaches more than 200 degrees. In the thermoacoustic engine, the turbine is in an inert gas medium — helium or argon, unlike a steam turbine, which wears out under the blows of droplets contained in a pair. Thus, we can expect an increase in the resource of the turbogenerator in a thermoacoustic engine compared to a steam turbine generator.

Thermo-acoustic engine can use almost any source of thermal energy, as it is an engine with an external heat supply, as well as a Stirling engine. At the same time, it has a very low temperature difference between hot and cold heat exchangers, which is necessary for starting the engine (the lowest temperature difference found in the literature is 17 degrees). Therefore, it is obvious that this engine solves the problem using different types of thermal energy.

Let's see how a thermo-acoustic generator can be cheaper than a generator on a Stirling engine and a steam turbine one.

- Firstly due to the use of standard pipes as a resonator body. Unlike the Stirling engine, the case of a thermo-acoustic engine should not have a high precision of manufacture. Usual steel pipes without turning will fit.

- Then, in comparison with the free-piston Stirling engine, the thermo-acoustic generator has not a linear, but a rotating generator, which reduces its material consumption, and, consequently, its cost.

- Finally, the turbogenerator, since it works almost at room temperature, it can use plastic parts in its composition, which reduces its manufacturing cost.

Thus, the thermoacoustic generator brought to a commercial model should occupy its niche in the micro-CHP market.