Lithium Ion UPS: Which type of battery to choose, LMO or LFP?

Today, almost everyone has a phone in his pocket (smartphone, camera phone, tablet) that can outperform your home desktop, which you haven’t updated for several years. Each gadget has a lithium-polymer battery. Now the question is: who among the readers will remember exactly when the irrevocable transition from “dialers” to multifunctional devices occurred?

It is difficult ... We must strain our memory, remember the year of purchase of the first "smart" phone. For me, this is about 2008-2010 year. At that time, the capacity of a lithium battery for a regular phone was about 700 mAh, now the capacity of the phone batteries reaches 4 thousand mAh.

The increase in capacity by 6 times, despite the fact that, roughly speaking, the battery size has increased only 2 times.

Like usalready told in our article , lithium-ion solutions for UPS are rapidly conquering the market, they have a number of indisputable advantages and are safe enough in operation (especially in the server environment).

Friends, today we will try to understand and compare solutions on iron-lithium-phosphate batteries (LFP) and lithium-manganese (LMO), to study their advantages and disadvantages, to compare among themselves on a number of specific indicators. I recall that both types of batteries belong to lithium-ion, lithium-polymer batteries, but differ in chemical composition. If you are interested in the continuation, please under the cat.

Prospects for lithium energy storage technologies

The current situation in the Russian Federation for 2017 was as follows.

clickable

With the use of the source: "The concept of the development of energy storage systems in the Russian Federation", the Ministry of Energy of the Russian Federation, August 21, 2017.

As you can see, at that time, the lithium-ion technology was among the leaders in approaching industrial production technology (primarily LFP technology was implied).

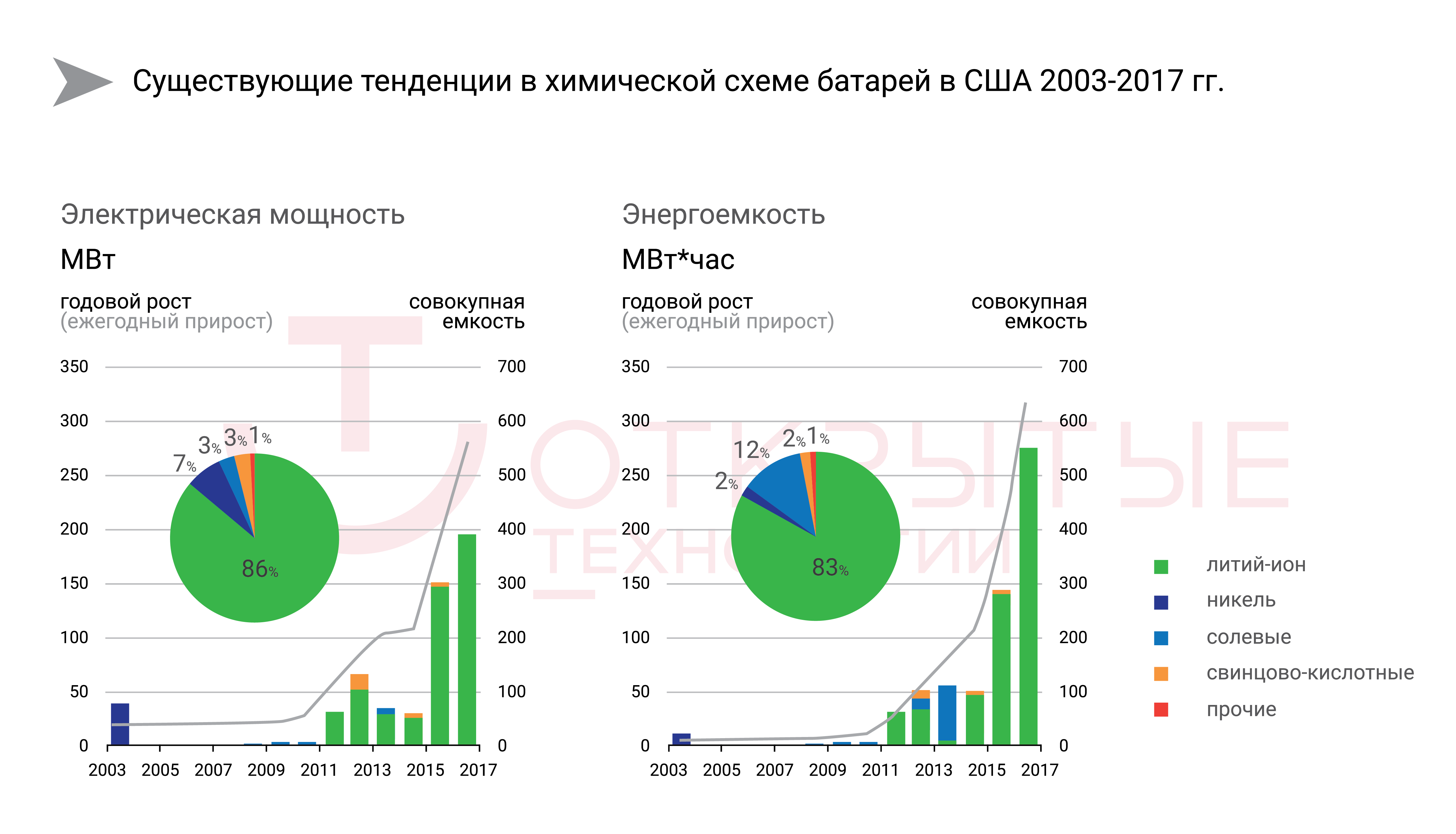

Next, we will look at trends in the USA, more precisely, we will consider the latest version of the document:

Reference: ABBM - energy arrays for uninterruptible power supplies that are used in the power industry for:

- Electricity reservations for especially important consumers in case of interruptions in power supply for own needs (SN) of 0.4 kV at the substation (PS).

- As a "buffer" drive for alternative sources.

- Compensation of power shortages in the peak consumption mode for unloading generation and transmission facilities for electricity.

- Energy savings during the day during its low cost (night time).

clickable

As you can see, as of 2016, Li-Ion technology firmly held the leading position and showed a rapid increase in both power (MW) and energy (MW * h).

In the same document we can read the following:

“Lithium-ion technologies represent more than 80% of the added power and energy of ABBM systems produced in the USA at the end of 2016. Lithium-ion batteries have a highly efficient cycle (charge, author's note) and give up accumulated power faster. In addition, they have a high energy density (power density, author's note) and high recoil currents, which led to their choice as batteries for portable electronics and electric vehicles. ”

Let's try to compare two technologies of lithium-ion batteries for UPS

We will compare the prismatic cells built on the chemistry of LMO and LFP. These two technologies (with variations of the LMO-NMC type) are now the main industrial designs for various electric vehicles and electric vehicles.

Lyrical digression about batteries in electric cars can be read here.

Спросите, причём тут электротранспорт? Поясню: активное распространение электротранспорта на Li-Ion технологиях уже давно перешагнуло стадию опытных образцов. А как мы знаем, все новейшие технологии приходят к нам из дорогих, новейших сфер жизни. Например, масса автотехнологий пришла к нам из Формулы-1, множество новейших технологий вошло в нашу жизнь из космической сферы, и так далее… Поэтому, на наш взгляд, сейчас происходит проникновение литий-ионных технологий в промышленные решения.

Рассмотрим таблицу сравнения основных производителей, химии батарей и собственно автомобильных компаний, активно выпускающих электромобили (гибриды).

Выберем исключительно призматические ячейки, которые подходят под форм-фактор использования в ИБП. Как видим, литий-титанат (LTO-NMC) является аутсайдером по удельной запасённой энергии. Остаются три производителя призматических ячеек, пригодных для использования в промышленных решениях, в частности, в батареях для ИБП.

Приведу цитату и перевод из документа «Оценка жизненного цикла и длительности эксплуатации литиевых электродов для батарей электротранспорта — ячейки для LEAF, Tesla и автобусов VOLVO» (Оригинал «Life cycle assessment of long life lithium electrode for electric vehicle batteries- cell for LEAF, Tesla and Volvo bus» от 11 декабря 2017 года от Mats Zackrisson. Здесь исследуются большей частью химические процессы в батареях автотранспорта, влияние вибраций и климатических условий эксплуатации, вред для окружающей среды. Однако имеется одна любопытная фраза на предмет сравнения двух технологий литий-ионных батарей.

В вольном моем переводе выглядит так:

NMC технология показывает меньшее воздействие на окружающую среду в расчёте на километр пробега транспорта, чем LFP технология с металлическим анодом батарейной ячейки, но здесь сложно уменьшить или ликвидировать ошибки. Основной смысл выглядит как: более высокая плотность энергии NMC даёт меньший вес и таким образом меньшее электропотребление.

Рассмотрим таблицу сравнения основных производителей, химии батарей и собственно автомобильных компаний, активно выпускающих электромобили (гибриды).

Выберем исключительно призматические ячейки, которые подходят под форм-фактор использования в ИБП. Как видим, литий-титанат (LTO-NMC) является аутсайдером по удельной запасённой энергии. Остаются три производителя призматических ячеек, пригодных для использования в промышленных решениях, в частности, в батареях для ИБП.

Приведу цитату и перевод из документа «Оценка жизненного цикла и длительности эксплуатации литиевых электродов для батарей электротранспорта — ячейки для LEAF, Tesla и автобусов VOLVO» (Оригинал «Life cycle assessment of long life lithium electrode for electric vehicle batteries- cell for LEAF, Tesla and Volvo bus» от 11 декабря 2017 года от Mats Zackrisson. Здесь исследуются большей частью химические процессы в батареях автотранспорта, влияние вибраций и климатических условий эксплуатации, вред для окружающей среды. Однако имеется одна любопытная фраза на предмет сравнения двух технологий литий-ионных батарей.

В вольном моем переводе выглядит так:

NMC технология показывает меньшее воздействие на окружающую среду в расчёте на километр пробега транспорта, чем LFP технология с металлическим анодом батарейной ячейки, но здесь сложно уменьшить или ликвидировать ошибки. Основной смысл выглядит как: более высокая плотность энергии NMC даёт меньший вес и таким образом меньшее электропотребление.

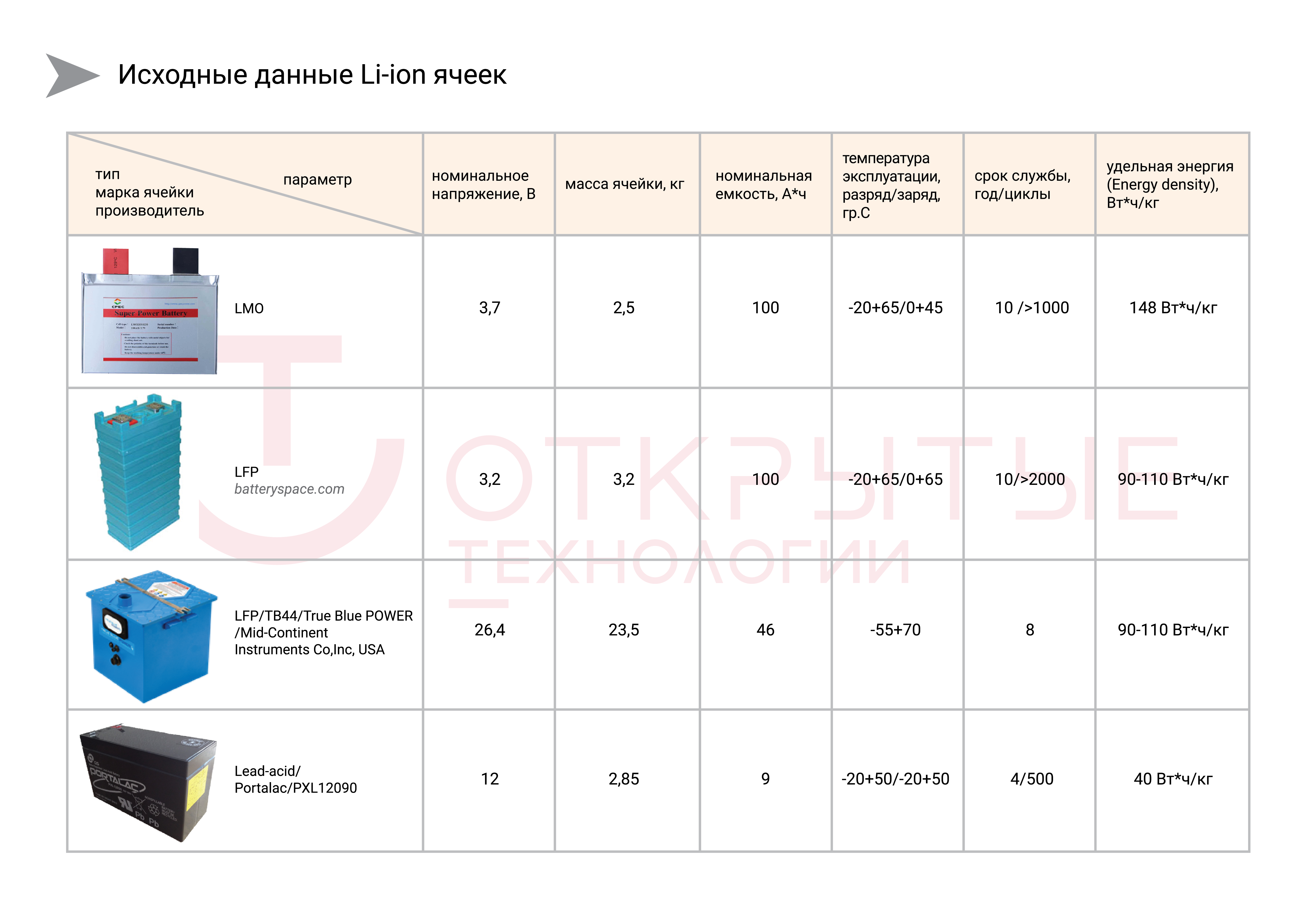

1) Prismatic cell LMO technology, manufacturer CPEC, USA , cost $ 400.

LMO cell appearance

2) Prismatic cell LFP technology, the manufacturer of AA Portable Power Corp , cost $ 160.

LFP cell appearance

3) For comparison, let's add an aviation backup battery built on LFP technology and the one that participated in the sensational Boeing fire scandal in 2013 , the manufacturer is True Blue Power.

TB44 Battery Appearance

4) For objectivity, add a standard battery UPS Lead-acid / Portalac / PXL12090, 12V.

Appearance of a classic UPS battery

Let's reduce the initial data in the table.

clickable

As you can see, LMO cells have indeed the highest energy efficiency; classic lead loses at least twice in specific energy.

It is clear to everyone that the BMS system for the Li-Ion battery array will add weight to this solution, that is, reduce the specific energy by about 20 percent (the difference between the net weight of the batteries and the complete solution, taking into account the BMS systems, module shell, battery cabinet controller). The mass of jumpers, battery switch and battery cabinet is assumed to be conditionally equal for lithium-ion batteries and the battery pack of lead-acid batteries.

Now we will try to compare the calculated parameters. In this case, we take the discharge depth for lead - 70%, and for Li-Ion - 90%.

clickable

Note that the low specific energy for an aviation battery is related to the fact that the battery itself (which can be considered as a module) is enclosed in a metal fireproof casing, has connectors and a heating system for operation at low temperatures. For comparison, the calculation is for a single cell as part of a TB44 battery, from which it can be concluded about similar characteristics with a conventional LFP cell. In addition, the aviation battery is designed for high charge / discharge currents, which is associated with the need to quickly prepare the aircraft for a new flight on the ground and high discharge current in case of an emergency on board, for example, loss of onboard power

By the way, this is how the manufacturer compares different types of aviation batteries.

As we can see from the tables:

1) The battery cabinet capacity is higher in the case of LMO technology.

2) The number of battery cycles for LFP more.

3) The specific gravity for LFP is less, respectively, with the same capacity, the battery cabinet of the iron-lithium-phosphate technology is larger.

4) LFP has less tendency to thermal acceleration due to its chemical structure. As a result, it is considered relatively safe.

For those who want to clearly understand how lithium-ion batteries can be connected to the battery pack to work with UPS, I recommend to look here.

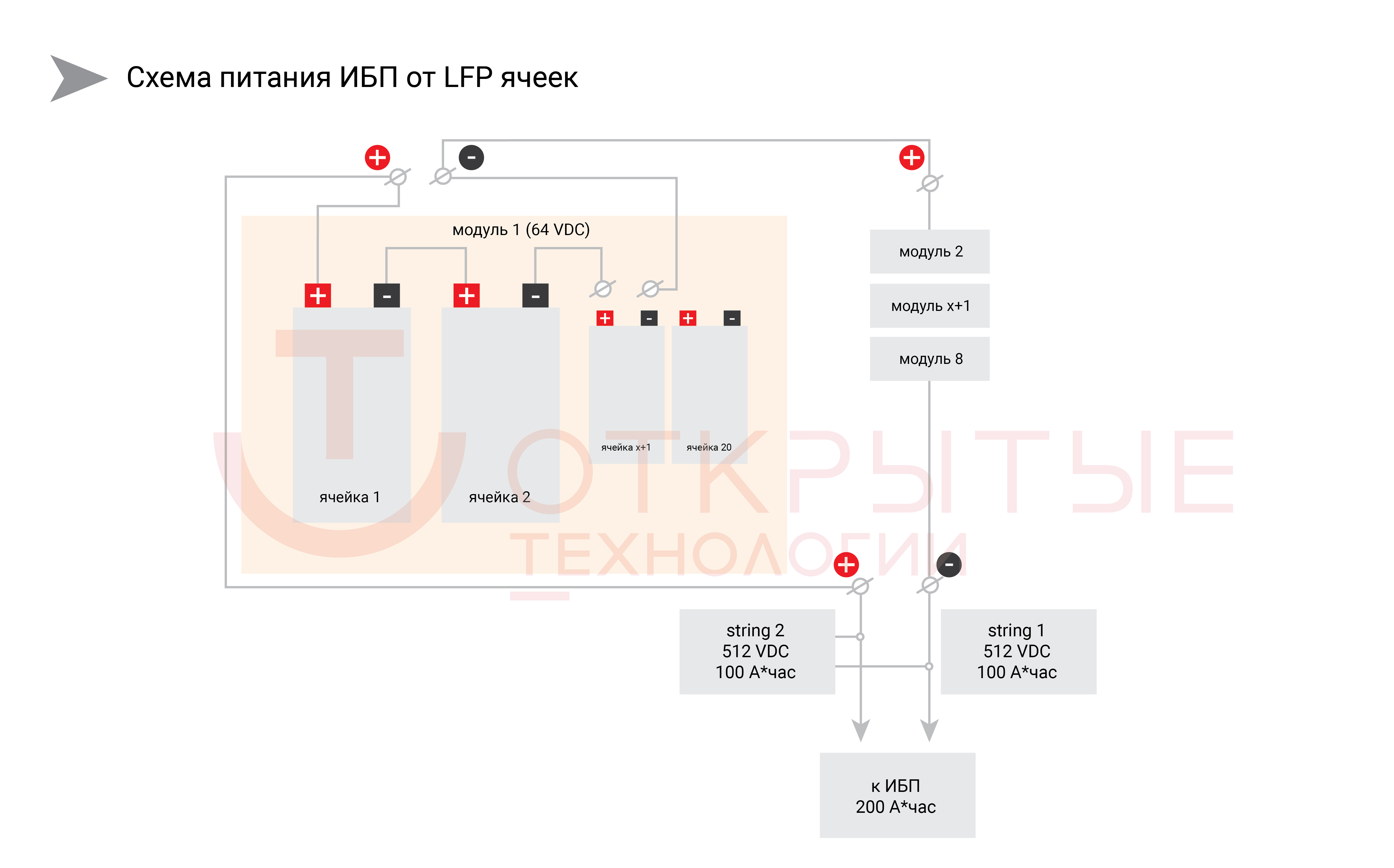

Например, такая схема. В данном случае чистый вес батарей будет 340 кг, ёмкость составит 100 ампер-часов.

кликабельно

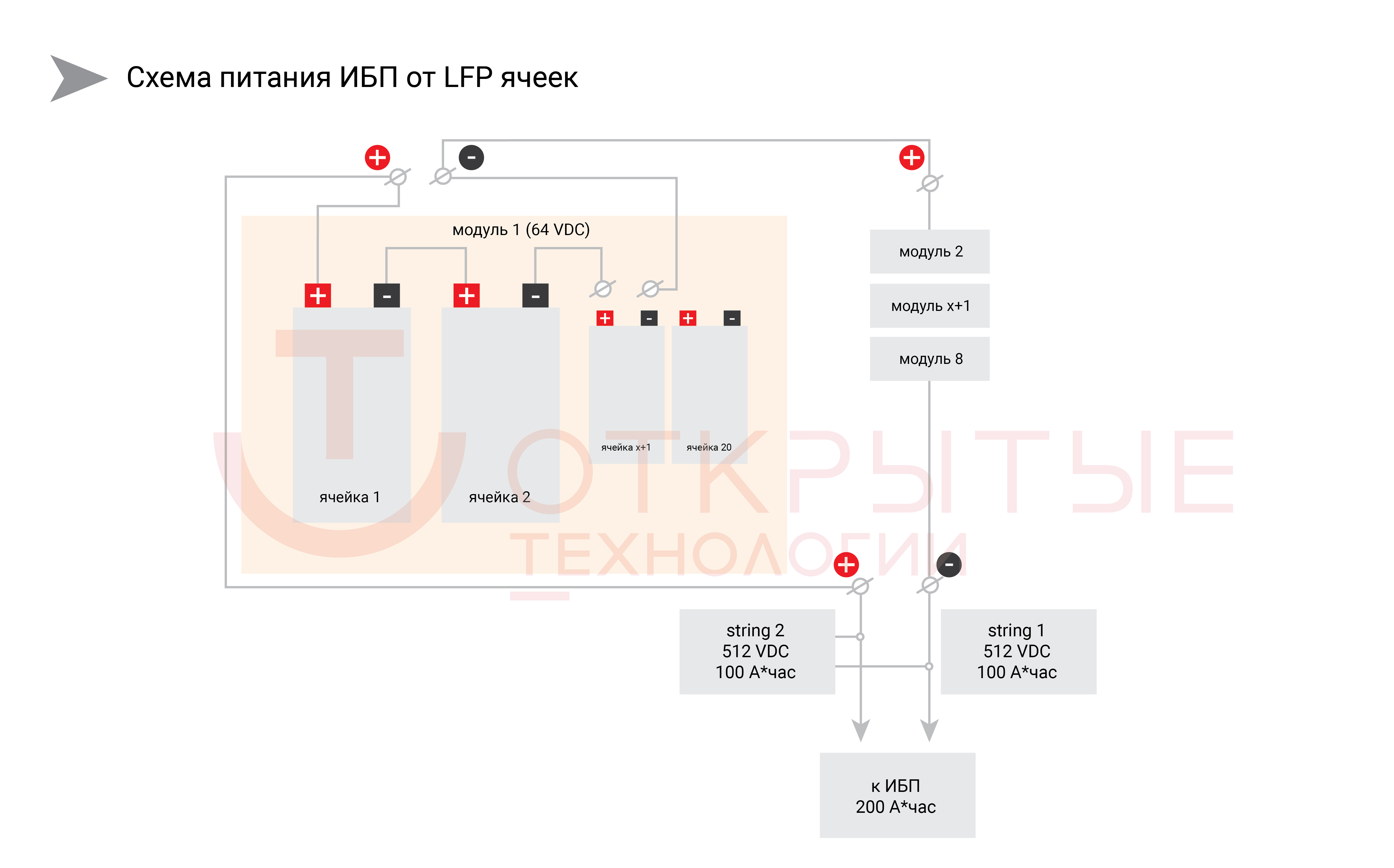

Или схема для LFP 160S2P, где чистая масса батарей будет 512 кг, а ёмкость — 200 ампер-часов.

кликабельно

кликабельно

Или схема для LFP 160S2P, где чистая масса батарей будет 512 кг, а ёмкость — 200 ампер-часов.

кликабельно

CONCLUSION:Although iron-lithium-phosphate (LiFeO4, LFP) chemistry batteries are used mostly in electric transport, their characteristics have several advantages over the chemical formula LMO, allow them to charge more current, and less at risk of thermal acceleration. What type of batteries to choose, remains at the discretion of the supplier of a complete integrated solution that determines this by a number of criteria, and last but not least the cost of the battery pack in the UPS. At the moment, any type of lithium-ion batteries is still losing in cost to classic solutions, but the high power density of lithium batteries per unit mass and smaller size will increasingly determine the choice in the direction of new energy storage devices. In some cases, a smaller gross mass of the UPS determines the choice in the direction of new technologies. This process will go completely unnoticed, and is currently hampered by the high cost in the low price segment (household solutions) and the inertia of thinking regarding lithium fire safety among customers who are looking for the best UPS in the industrial segment of the UPS with more than 100 kVA. The level of the average UPS power segment from 3kVA to 100kVA is possible for implementation on lithium-ion technologies, but due to small-scale production, it is rather expensive and loses to ready-made serial samples of UPS on VRLA batteries.

Learn more and discuss specific solution using lithium-ion batteries for your server or data center can, by sending a request by e-mail info@ot.ru , or by making a request on its website www.ot.ru .

OPEN TECHNOLOGIES - reliable integrated solutions from world leaders, adapted specifically to your goals and objectives.

Author: Oleg Kulikov

Leading Design Engineer

Department of Integration Solutions

Open Technologies Company