Geological 3D-modeling, logging and technaton from Aramco Innovations

Admit it, when it comes to oil production, Texas landscapes and mechanical “rockers” stand in front of the sunset sky. Someone will see another pipe-torches, burning associated gases, and maybe even a drilling platform somewhere on the sea shelf. Of course, oil production is a heavy business and is associated with certain risks. Huge machines, drilling machines, the risk of explosion and fire. Oil production in the minds of the masses is undoubtedly a brutal affair, for strong workers and almost the same strong engineers.

All of you are both right and wrong. Yes, oil was mined and mined with the help of “swings”, but this whole image, which we got from the movies and TV shows, no longer corresponds to the full picture; progressive companies are increasingly beginning to introduce the latest achievements in the field of IT. Modern oil companies simultaneously use the latest developments in the processing of BigData, AI, machine learning and many others. Below, based on the experience of Aramco Innovations, there will be several examples of how deeply IT technologies have penetrated such a seemingly classic and inert business as oil production.

It is worth starting with whose cases will be discussed. Aramco Innovations - Russian representative office of a research organization, which is part of the structure of the national oil producing company of Saudi ArabiaSaudi Aramco . The latter is the largest oil producer on the planet and is wholly owned by the Kingdom of Saudi Arabia. Specifically, Aramco Innovations is engaged in maternal organization research in the field of artificial intelligence (AI), high-performance computing systems and nanomaterials. The company recently opened an office in Moscow, as in one of the most promising places for the organization of scientific work in the fields of AI, BigData and machine learning.

If we pick up an explanatory dictionary and open it in “geo-modeling”, we will get something like the following definition: this is the design and creation of cartographic images based on the visualization of source, derived or final data. Obviously, in the oil industry, geomodeling is one of the central places. A significant part of the costs of oil companies around the world (and we are talking not only about Saudi Aramco, but in general about all oil producers) falls on exploration, followed by modeling the occurrence of hydrocarbons.

According to the generally accepted concept, geomodelling can be decomposed into the following stages:

In fact, three-dimensional reservoir modeling is a multi-step, complex process of field assessment for a variety of grounds, although at first glance it may seem that it is enough to determine “from where” and “where” hydrocarbons are located.

Why do we need geo-models of the field after the start of production? It is clear that the classic process of extracting hydrocarbons from the depths begins with direct exploration of the field. Geologists build his map, on the basis of which a complete computer model of the entire reservoir is created. This is done in order to develop a strategy for the development of the field, to place oil wells most profitably, to minimize losses from the displacement of reservoirs and to avoid accidents during production.

Schematic illustration of the most favorable location of an oil rig for oil production.

As can be understood, the clarity of a similar reservoir model decreases over time due to the fact that no single model can predict with 100% accuracy all changes in the structure of the rock and the field itself during oil production. . Above, we gave a schematic example of an oil field, but in reality everything is much more complicated. For example, Saudi Aramco is developing the world's largest oil field, Gavar , which was discovered in 1948. It contains up to 10-12 billion tons of oil, and the total area of the field is ~ 5300 square kilometers.

That is, we come to the fact that even explored active deposits require constant study and modeling, at least in order to understand where it is worth drilling, and where it is already useless or too expensive. It should be remembered that mineral deposits can occur in gigantic areas, that is, drilling and production occur simultaneously at a multitude of points. It is practically impossible to calculate and predict changes in the field structure manually; therefore, the task of modeling active fields is transferred to the plane of developing IT systems and processing large data arrays.

This is where work begins for IT professionals in the areas of AI, BigData, and machine learning. Since about the 1960s, oil companies have begun to collect a lot of data on developed fields. Over time, this information has become a huge stream of all sorts of data, obtained both during exploration and in the process of drilling and production. Based on this information, specialists want to train neural networks to more quickly and accurately model the behavior of the fields being developed in the near future.

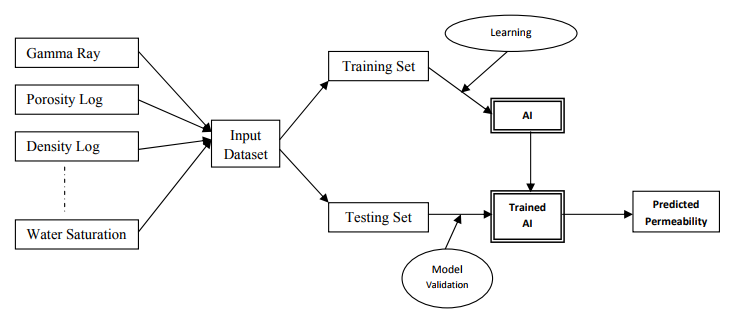

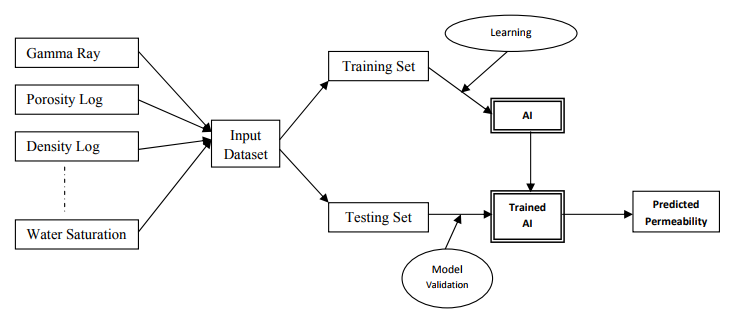

A lot of work has already been done in this direction and a number of studies have been conducted. So, in one of them the following types of field data are fed to the input of the neural network:

At the exit, researchers receive predictions on temperature, pressure, structure and compaction of the rock, and even the recommended distance between the towers. In addition to assessing the deposits themselves, such systems can also be used to predict problems during drilling and the production itself, which anticipates accidents, breakdowns and the occurrence of unplanned losses.

If we talk about drilling, it is worth remembering about the logging curves and the study of wells. Logging- This is a method of geophysical research wells. Of course, the most obvious way to evaluate the structure of a well is to raise the core — cutting out the rock followed by a physical study of the entire “pillar”. However, drilling engineers will not allow to lie: the process of cutting and lifting core costs a lot of monstrous money and is fraught with a number of technical difficulties. First of all, it's a long time. It is one thing to drill a well, raising the crushed rock to the surface in a drilling mud, and another to cut a pole and raise it in the form in which it lies. For this reason, modern logging uses geophysical probes that descend into the well to study the walls of the well and near-wellbore space and collect information “from the inside”.

Logging probes are equipped with a whole range of passive and active sensors. Passive sensors collect information about the magnetic and spontaneous electric field, natural gamma radiation, and so on. Active sensors are receivers and sources of artificially created electrical, acoustic, and other fields and radiations. Using a logging probe, geophysicists collect information at certain intervals of the well, which are then formed into logging curves.

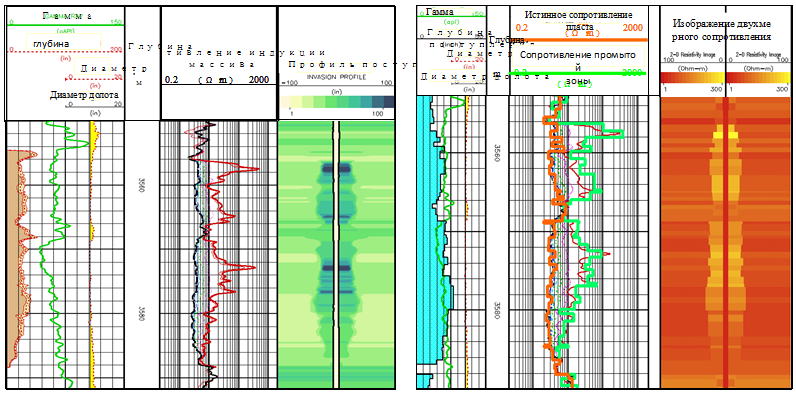

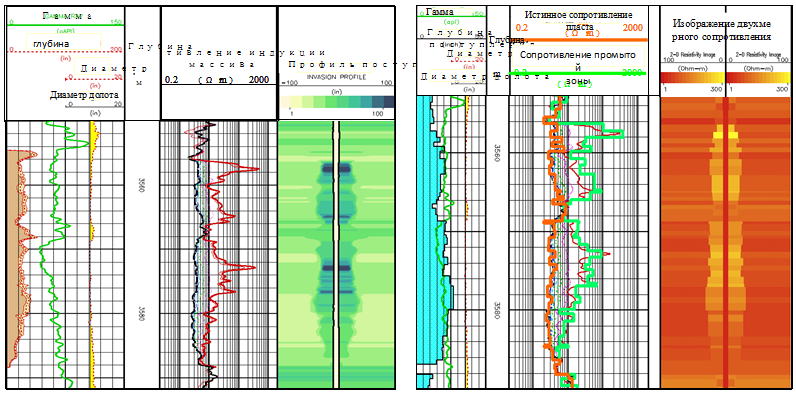

An example of logging curves constructed by several parameters.

The data collected from a well are further processed by geologists, and this is a very laborious and laborious process, which often occurs in manual mode.

Aramco Innovations is working to create logging interpretation systems based on machine learning technologies. Most of the work with curves is a typical monkey-job, which comes down to finding the points of dependencies and differences with the data already available to geologists. Machine learning is best suited for identifying these dependencies in logging curves with the subsequent formation of the final report, which is already analyzed by a specialist. Such an approach can significantly increase the efficiency of well surveys and speeds up the process of well assessment and exploration as a whole.

Also, machine vision is planned to be used to analyze the structure of deep seams based on images obtained during seismic prospecting. The greatest value for geologists on them are oil-bearing horizons and cracks in the rock, which can pose a potential threat during the mining of minerals. Now experts of Aramco Innovations are working to delegate the most dreary and monotonous work of the machines, leaving people only the function of the final analysis and decision making.

Above, we described only a few areas of application of modern achievements of the IT sphere in oil production. Their importance is difficult to overestimate: we literally live in a plastic world. Virtually all of the objects surrounding us, to one degree or another, were created either from oil and derivatives, or from materials derived from the combustion of carbon fuel.

This weekend, from October 26 to October 28, Aramco Innovations together with the Moscow State University Science Park are hosting the Aramco Upstream Solutions Technathon in Moscow , an event dedicated to the use of Artificial Intelligence technologies for the oil industry.

The main objective of the event is to evaluate and encourage the scientific potential in the field of machine learning and artificial intelligence, as well as to find potential candidates who want to join the Aramco Innovations team. On the first day, October 26, from 12:00 to 16:00, all participants will be able to listen to popular science lectures on the objectives of the event. The purpose of the lectures is to give an idea of oil production to those who are far from the industry. Lectures, as well as technathon itself, are absolutely free.

The technathon final will be held on October 28, within its framework 3 winning teams will be awarded, and 2 special prizes will be awarded for solving problems marked by the judges. The prize fund technathon is 7000 US dollars (about 470 000 rubles). Participants will have 48 hours of coding and work with leading experts from the Saudi Aramco Science Center.

First of all, IT specialists in the field of machine learning and AI, specialists of technical professions, geologists and geophysics are invited to participate.

More information about the rules, schedule and rules of the event you can find here . To participate in technathon you need to register for free before October 26, 17:50 GMT.

We are waiting for all interested specialists on October 26, at 18:00 at the address Moscow, Moscow State University Science Park, ul. Lenin Mountains, 1s77.

If you have any additional questions about the event, write to ab@codenrock.com or ask in the event's Telegram channel .

All of you are both right and wrong. Yes, oil was mined and mined with the help of “swings”, but this whole image, which we got from the movies and TV shows, no longer corresponds to the full picture; progressive companies are increasingly beginning to introduce the latest achievements in the field of IT. Modern oil companies simultaneously use the latest developments in the processing of BigData, AI, machine learning and many others. Below, based on the experience of Aramco Innovations, there will be several examples of how deeply IT technologies have penetrated such a seemingly classic and inert business as oil production.

It is worth starting with whose cases will be discussed. Aramco Innovations - Russian representative office of a research organization, which is part of the structure of the national oil producing company of Saudi ArabiaSaudi Aramco . The latter is the largest oil producer on the planet and is wholly owned by the Kingdom of Saudi Arabia. Specifically, Aramco Innovations is engaged in maternal organization research in the field of artificial intelligence (AI), high-performance computing systems and nanomaterials. The company recently opened an office in Moscow, as in one of the most promising places for the organization of scientific work in the fields of AI, BigData and machine learning.

Geological 3D-modeling of deposits

If we pick up an explanatory dictionary and open it in “geo-modeling”, we will get something like the following definition: this is the design and creation of cartographic images based on the visualization of source, derived or final data. Obviously, in the oil industry, geomodeling is one of the central places. A significant part of the costs of oil companies around the world (and we are talking not only about Saudi Aramco, but in general about all oil producers) falls on exploration, followed by modeling the occurrence of hydrocarbons.

According to the generally accepted concept, geomodelling can be decomposed into the following stages:

- training;

- structural modeling;

- creating a three-dimensional grid;

- averaging well data over three-dimensional grid cells;

- lithologic - facial modeling;

- petrophysical modeling;

- saturation modeling;

- 3D inventory calculation.

In fact, three-dimensional reservoir modeling is a multi-step, complex process of field assessment for a variety of grounds, although at first glance it may seem that it is enough to determine “from where” and “where” hydrocarbons are located.

Why do we need geo-models of the field after the start of production? It is clear that the classic process of extracting hydrocarbons from the depths begins with direct exploration of the field. Geologists build his map, on the basis of which a complete computer model of the entire reservoir is created. This is done in order to develop a strategy for the development of the field, to place oil wells most profitably, to minimize losses from the displacement of reservoirs and to avoid accidents during production.

Schematic illustration of the most favorable location of an oil rig for oil production.

As can be understood, the clarity of a similar reservoir model decreases over time due to the fact that no single model can predict with 100% accuracy all changes in the structure of the rock and the field itself during oil production. . Above, we gave a schematic example of an oil field, but in reality everything is much more complicated. For example, Saudi Aramco is developing the world's largest oil field, Gavar , which was discovered in 1948. It contains up to 10-12 billion tons of oil, and the total area of the field is ~ 5300 square kilometers.

That is, we come to the fact that even explored active deposits require constant study and modeling, at least in order to understand where it is worth drilling, and where it is already useless or too expensive. It should be remembered that mineral deposits can occur in gigantic areas, that is, drilling and production occur simultaneously at a multitude of points. It is practically impossible to calculate and predict changes in the field structure manually; therefore, the task of modeling active fields is transferred to the plane of developing IT systems and processing large data arrays.

This is where work begins for IT professionals in the areas of AI, BigData, and machine learning. Since about the 1960s, oil companies have begun to collect a lot of data on developed fields. Over time, this information has become a huge stream of all sorts of data, obtained both during exploration and in the process of drilling and production. Based on this information, specialists want to train neural networks to more quickly and accurately model the behavior of the fields being developed in the near future.

A lot of work has already been done in this direction and a number of studies have been conducted. So, in one of them the following types of field data are fed to the input of the neural network:

- information on the intensity of gamma radiation;

- porosity;

- density;

- water saturation;

- other.

At the exit, researchers receive predictions on temperature, pressure, structure and compaction of the rock, and even the recommended distance between the towers. In addition to assessing the deposits themselves, such systems can also be used to predict problems during drilling and the production itself, which anticipates accidents, breakdowns and the occurrence of unplanned losses.

Interpretation of data and logging curves

If we talk about drilling, it is worth remembering about the logging curves and the study of wells. Logging- This is a method of geophysical research wells. Of course, the most obvious way to evaluate the structure of a well is to raise the core — cutting out the rock followed by a physical study of the entire “pillar”. However, drilling engineers will not allow to lie: the process of cutting and lifting core costs a lot of monstrous money and is fraught with a number of technical difficulties. First of all, it's a long time. It is one thing to drill a well, raising the crushed rock to the surface in a drilling mud, and another to cut a pole and raise it in the form in which it lies. For this reason, modern logging uses geophysical probes that descend into the well to study the walls of the well and near-wellbore space and collect information “from the inside”.

Logging probes are equipped with a whole range of passive and active sensors. Passive sensors collect information about the magnetic and spontaneous electric field, natural gamma radiation, and so on. Active sensors are receivers and sources of artificially created electrical, acoustic, and other fields and radiations. Using a logging probe, geophysicists collect information at certain intervals of the well, which are then formed into logging curves.

An example of logging curves constructed by several parameters.

The data collected from a well are further processed by geologists, and this is a very laborious and laborious process, which often occurs in manual mode.

Aramco Innovations is working to create logging interpretation systems based on machine learning technologies. Most of the work with curves is a typical monkey-job, which comes down to finding the points of dependencies and differences with the data already available to geologists. Machine learning is best suited for identifying these dependencies in logging curves with the subsequent formation of the final report, which is already analyzed by a specialist. Such an approach can significantly increase the efficiency of well surveys and speeds up the process of well assessment and exploration as a whole.

Also, machine vision is planned to be used to analyze the structure of deep seams based on images obtained during seismic prospecting. The greatest value for geologists on them are oil-bearing horizons and cracks in the rock, which can pose a potential threat during the mining of minerals. Now experts of Aramco Innovations are working to delegate the most dreary and monotonous work of the machines, leaving people only the function of the final analysis and decision making.

Technathon Aramco Innovations

Above, we described only a few areas of application of modern achievements of the IT sphere in oil production. Their importance is difficult to overestimate: we literally live in a plastic world. Virtually all of the objects surrounding us, to one degree or another, were created either from oil and derivatives, or from materials derived from the combustion of carbon fuel.

This weekend, from October 26 to October 28, Aramco Innovations together with the Moscow State University Science Park are hosting the Aramco Upstream Solutions Technathon in Moscow , an event dedicated to the use of Artificial Intelligence technologies for the oil industry.

The main objective of the event is to evaluate and encourage the scientific potential in the field of machine learning and artificial intelligence, as well as to find potential candidates who want to join the Aramco Innovations team. On the first day, October 26, from 12:00 to 16:00, all participants will be able to listen to popular science lectures on the objectives of the event. The purpose of the lectures is to give an idea of oil production to those who are far from the industry. Lectures, as well as technathon itself, are absolutely free.

The technathon final will be held on October 28, within its framework 3 winning teams will be awarded, and 2 special prizes will be awarded for solving problems marked by the judges. The prize fund technathon is 7000 US dollars (about 470 000 rubles). Participants will have 48 hours of coding and work with leading experts from the Saudi Aramco Science Center.

First of all, IT specialists in the field of machine learning and AI, specialists of technical professions, geologists and geophysics are invited to participate.

More information about the rules, schedule and rules of the event you can find here . To participate in technathon you need to register for free before October 26, 17:50 GMT.

We are waiting for all interested specialists on October 26, at 18:00 at the address Moscow, Moscow State University Science Park, ul. Lenin Mountains, 1s77.

If you have any additional questions about the event, write to ab@codenrock.com or ask in the event's Telegram channel .