Review UP! 3D Printer Mini

This model has attracted my attention and I want to share with the public, for the reason that it is a finished, finished, configured (you can get out of the box and print) printer for the price of a kit for self-assembly. (45 000 rubles, the price of the warehouse in Moscow, that is, already taking into account the "customs").

This printer is simple .

(If you want to know what is "difficult" - read here , here or here . And you can also find the lucky one who has a Solidoodle printer).

This printer is cheap .

Compared to Up! Plus 2 for 83 thousand rubles, Picaso, Ultimaker 2, Printbox3d, Replicatort 2 (which are in Moscow) - more than 99 thousand rubles.

This printerworks . It does not need to be assembled in pieces, it already has all the settings and drivers, all parameters are set, etc.

You just need to download the software from the site, download the 3D model, enter the platform level and send it to print.

This printer is for those who need to quickly and easily get ready-made prototypes / toys. Since it is closed, this gives additional security (children, pets).

Cheeky slogan on the box

Under the cut are a few photos of printer contents and short comments.

TTX

Material used for printing models

ABS plastic filament diameter 1.75mm, white / color

Workspace size

120mm (width) x 120mm (depth) x 120mm (height)

Layer thickness

0.25 / 0.30 / 0.35mm

Compatible with

Windows software : Windows XP , Windows Vista, Windows 7; MAC

Dimensions and weight

240mm (width) x 340mm (depth) x 355mm (height); Weight - 6kg

Power requirements

100-240 V, 50-60 Hz, 220W

ABS plastic filament diameter 1.75mm, white / color

Workspace size

120mm (width) x 120mm (depth) x 120mm (height)

Layer thickness

0.25 / 0.30 / 0.35mm

Compatible with

Windows software : Windows XP , Windows Vista, Windows 7; MAC

Dimensions and weight

240mm (width) x 340mm (depth) x 355mm (height); Weight - 6kg

Power requirements

100-240 V, 50-60 Hz, 220W

The printer prints with ABS , PLA , Crystal Flex plastic.

Since one of the common situations is the model’s deformation due to a “temperature gradient” (read - if a draft blew, on one side the part cooled down and the whole structure was deformed by 2-3 mm), then one one of the solutions is to make a closed case.

This printer has a sealed enclosure.

(But in fact, not everything is so simple, because the engines that move the platform and the print head are inside the case, and they begin to fail at temperatures above 80 degrees).

A closed case does not solve all problems, but at least it solves this problem (garbage bag on a 3D printer).

Appearance

Side view:

Rear view:

Stylish button:

Accessories:

Coil of original ABS plastic in a vacuum package. (700gr)

2 more platforms, a power cord, a date cable, hexagons, a pin for hanging coils, a tube for feeding plastic.

Power supply:

As usual for Up printers - the power supply is huge. 20V and 10A

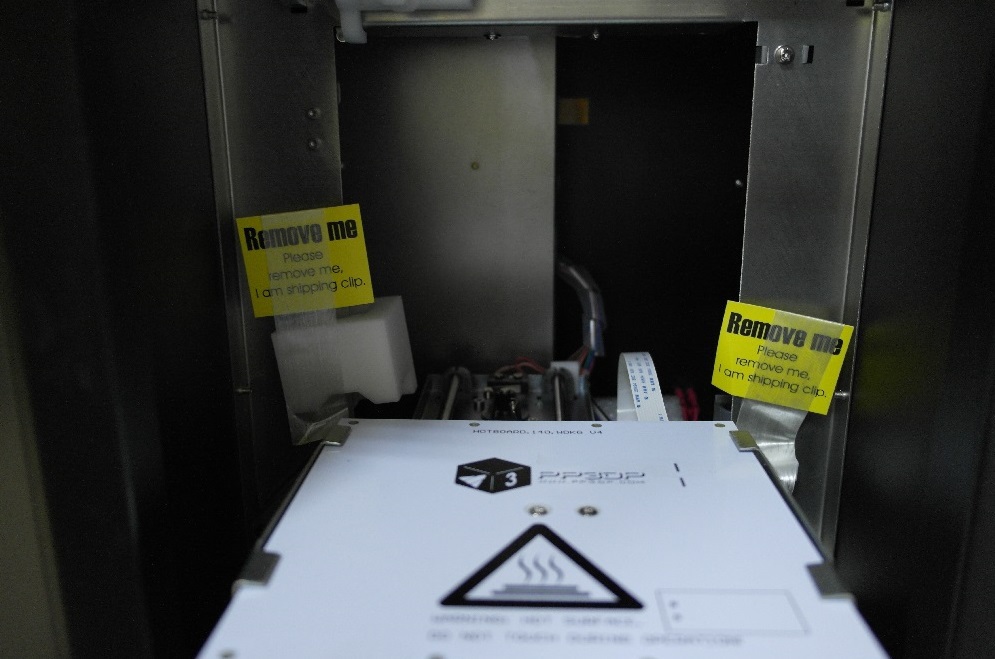

Open the door

In this photo you can see “reminders” - that transportation fasteners must be removed, and some of them were left inside, and then complained that the printer was “knocking”.

It is also seen that there is a design feature of the platform - it is on springs - and on the sides of the mount.

(By the way, there is only 1 bolt for calibration, the developers decided that this was enough.)

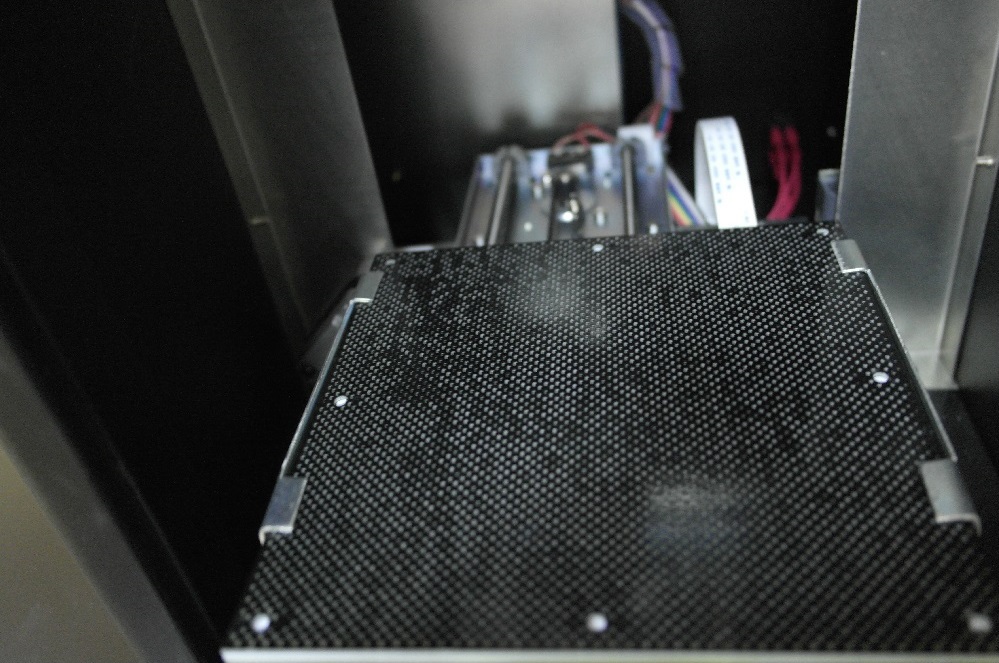

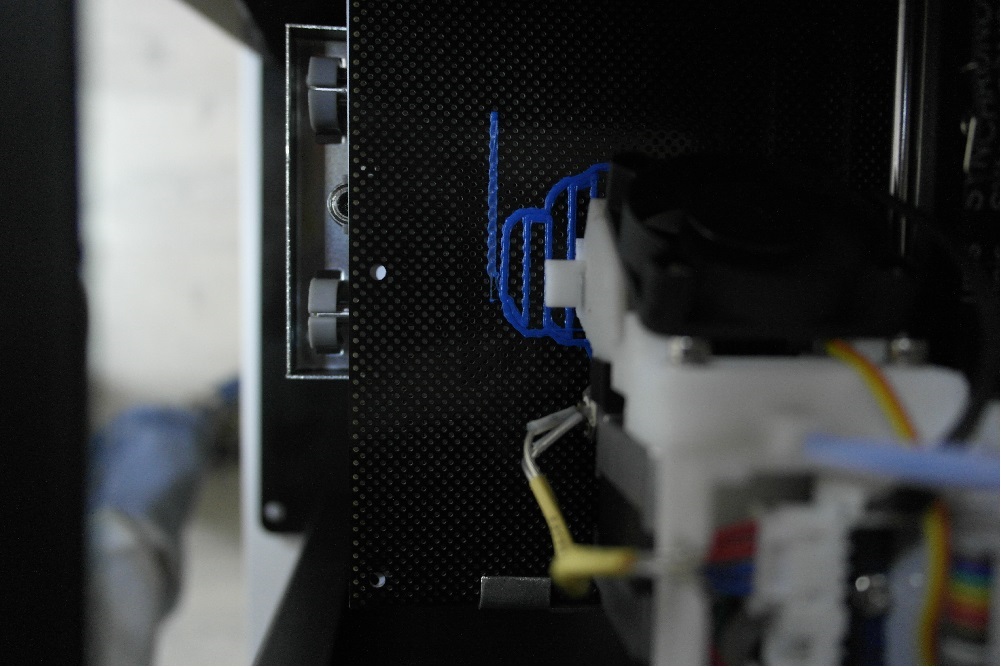

Platform installed:

The platform does not fall with a clang, but gradually lowers.

This photo shows how the platform is inserted and how the grooves hold it. Printhead

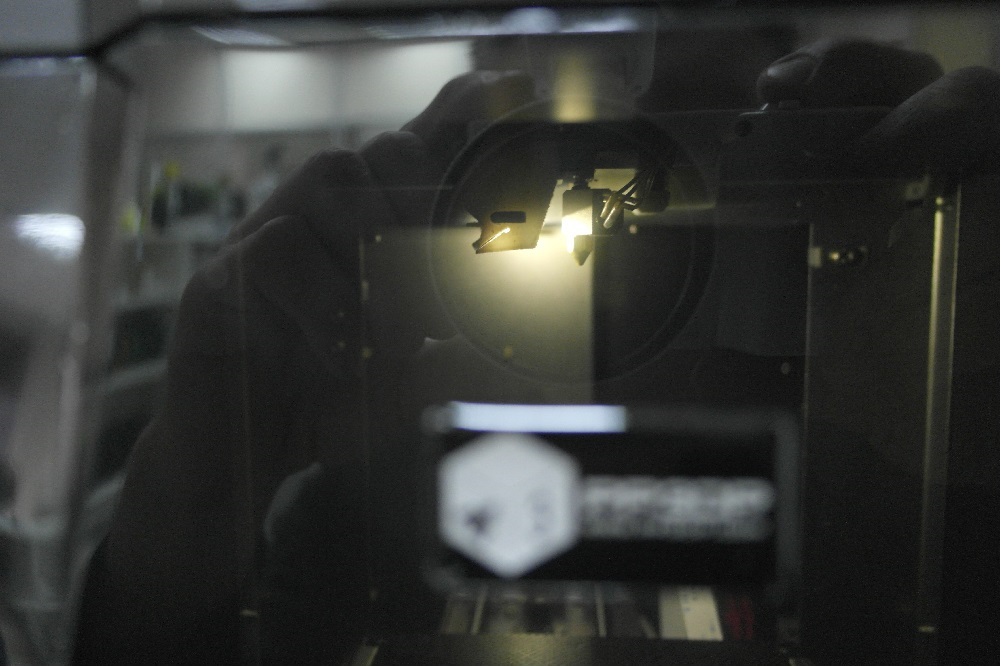

:

2-pin printhead (backlight and fan). With fun colored wires.

Backlight:

Backlight - so that you can observe the process without opening the door.

Unscrew and look inside

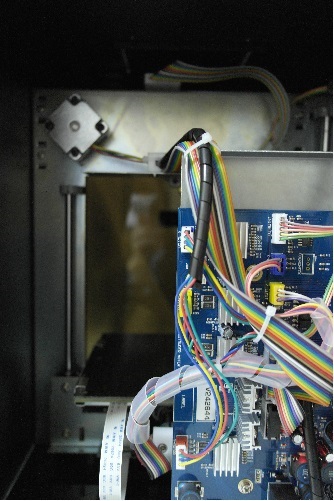

Electronics: A

board with ominous “terminator” LEDs (very similar to Up! Plus 2 in quality, unlike the old version ).

Frame:

Steel structure. Guide axes are double. Can be operated 24/7.

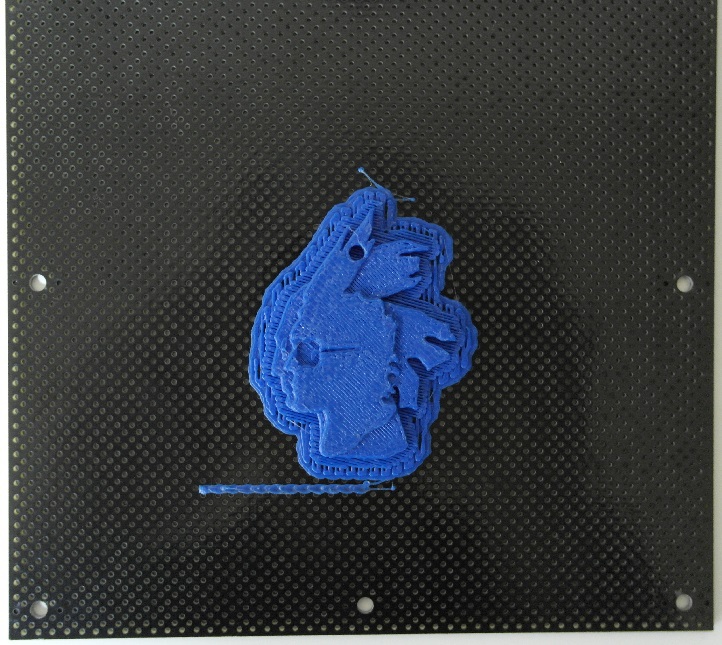

First seal

First you need to set the height of the platform. It takes 1 minute.

Next, download the 3D model and send it to print.

This time I chose the "tribal Indian", and set the maximum print speed.

The program produced an expected print time of 8 minutes.

Start of printing:

End of printing:

“Two-color” printing:

Software

The printer software is downloaded from the manufacturer's website (PP3DP.com), similar to UP! Plus 2

There are 2 types of printers: those who use "open software" and those who use their own software.

Both of them have their advantages.

Open software claims to be universal, to be able to improve the code itself and the ability to configure “9000” parameters. Open software gives complete freedom (in the binding - full responsibility) to the user. If you are a lover of settings accurate to a micron and to fractions of a degree, then this is a find for you. But you can insert plastic from any manufacturer and for some time get the optimum print temperature for it.Own software from the manufacturerguarantees 100% compliance with hardware and software. Also, its own software from the manufacturer suggests that 95% of the "9000" parameters are already debugged by professional technicians, and the company is responsible for this (in some way). Software from the manufacturer allows you to avoid installing additional programs, several (tens, hundreds) hours of configuration, and makes it possible to "unpack and print". No need to think about the form of filling and the minimum wall thickness, because There are manufacturer-preset presets. With software from the manufacturer it is more difficult to spoil the printed part than with "open software." Printers with software from the manufacturer have recommended suppliers of consumables (coils), which are covered by the "guarantee" that this printer will print optimally with this material.

Only large companies (3d systems, Makerbot, PP3DP, etc.) or some startups that make a special bet on software can afford to develop their own software.

Minuses

1. The layer thickness is only 200 microns

(Up! Plus 2 - 150 microns, Replicator 2 - 100 microns)

2. Small print surface

120mm (width) x 120mm (depth) x 120mm (height) UP! 3D Printer Mini (44 900 rub)

140mm (width) x 140mm (depth) x 135mm (height) Up! plus 2 (82 900 rub)

285mm (width) x 153mm (depth) x 155mm (height) MakerBot Replicator 2 (115 000 rub)

250mm (width) x 200mm (depth) x 200mm (height) ShareBot NG (129 000 rub)

3. Lack of automatic calibration

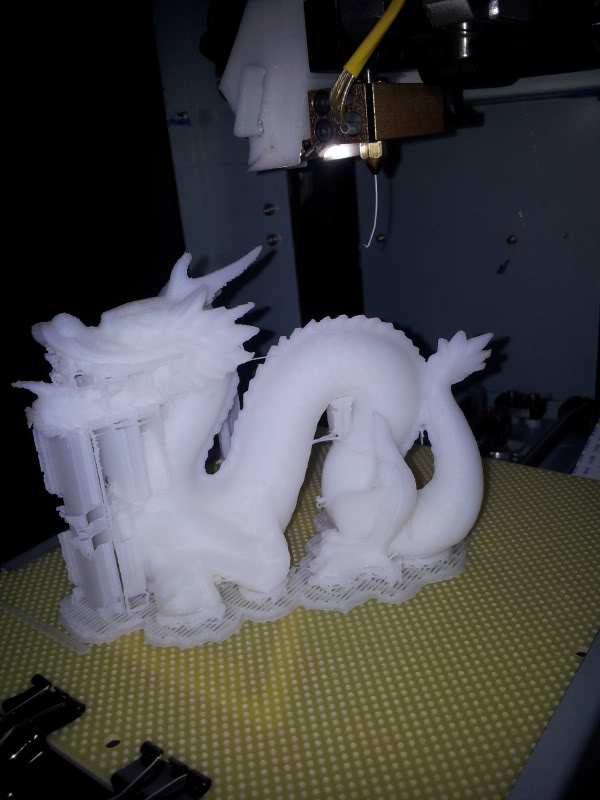

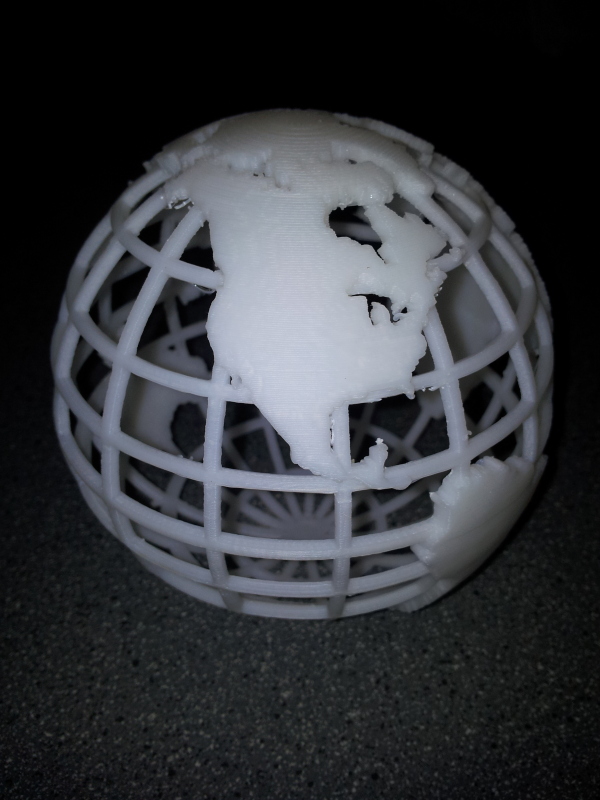

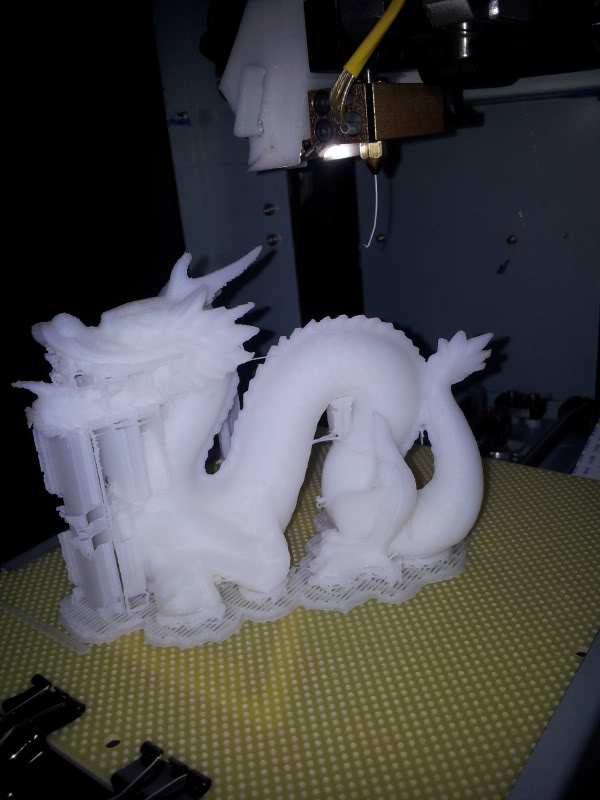

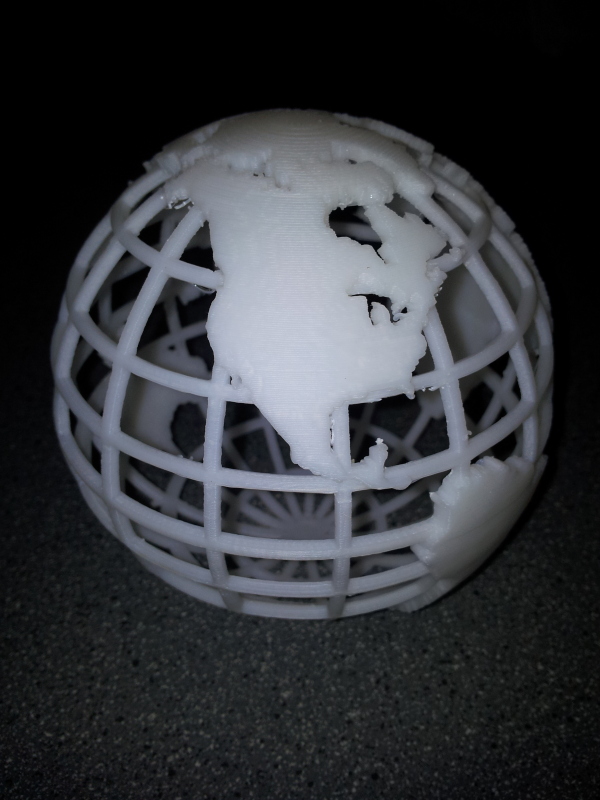

But these minuses do not prevent the minicab from printing such things:

Work examples

PS

Eiffel Tower meter printed on UP! 3D Printer Mini (consists of 13 parts)

PPS

Video in Russian about "mini":

Peppy video from foreign comrades: