Aeroexpress: go to the depot

Let’s talk about how Aeroexpress is arranged, why there is almost no noise in it, where the battery was put to it, and how everything is arranged in the train itself. And in the depot, too, because Aeroexpress has its own trains, its own depot for servicing them, and its own crew of drivers. That is, everything is different, except for rails and electricity.

In this photo from the depot, three generations of electric trains are visible: the new double-decker train ESH2, the rather old ED4 (this was the first generation of express trains to the airport) and EG2T, which is “average” by characteristics between them is a good workhorse, which is also being repaired at the Aeroexpress depot.

Work in the driver's cab.

This is a very, very interesting example of a company on the infrastructure of Russian Railways.

Aeroexpress is a comfortable electric train to the airports of the Moscow aviation hub (Vnukovo, Domodedovo and Sheremetyevo) from Kiev, Paveletsky and Belorussky stations from Moscow. A quick way to get from the city to the airport with a minimum of stops: from Domodedovo there is a stop on the transfer circuit of Verkhny Kotlov, and from Sheremetyevo - now to Okruzhnaya, and all this is past traffic jams. As elsewhere in the world, this method is more expensive than classic public transport, but cheaper than a taxi. According to international definitions, transportation is considered intermodal, since seamless transportation is the delivery of passengers from the hub to the hub (from the airport to the station).

In 2005-2007, the company only sold tickets. Rolling stock and everything connected with it was leased from Russian Railways. In 2008, the first own trains were purchased (which still run on the Sheremetyevo direction). Here is one of them for maintenance:

In 2011, the first own locomotive crew appeared, that is, in addition to trains, the Aeroexpress company began to operate.

In 2012, they took away the service for themselves, for which they took a long-term lease of an old depot near the Belorussky railway station, built in the 19th century for steam locomotives. Here is the turning circle:

The fan part is a depot built in the 19th century. Behind it is the already normal, more modern depot of the 1960 model of three steps (rooms). It is these three steps that Aeroexpress took and began to modernize.

Historically, this is a train depot. Each step was supposed to accommodate two steam locomotives on one ditch (from several ditches), that is, the length of the hulls was 72 meters per step. Then, due to new types of traction - diesel and electric - the depot was expanded. The first stage has remained unchanged. The second lengthened, to the part with arches completed the continuation. Here are the old arches:

The second step became 125 meters. The third step is the newest part, already 260 meters long, it was completed the longest. This is now the only depot in Moscow and the region with a workshop not of a straight line, but of a curved shape. This curved part was completed in 1975-1976 due to the development of suburban transport. Then suburban trains consisted of two cars, then - of six on an electric train of Riga production. Then complexity began to grow. Depot was built on 12 cars ER2 (now these trains are almost all written off). The Latvian plant, by the way, still makes components that are used in ED4, new EP2, and on the Orioles from the third number - also components of the Riga factory. Now Latvia makes the electric part, delivers car sets to the TVZ, and there they are assembled, commissioned, tested, and put into operation.

Shunting work is also carried out by the company on its own locomotives.

In 2012, it became clear that passenger traffic would increase. Three years later, a new solution was needed. The traditional is to attach more wagons. But the estimated 12 cars did not fit on the platform, and modifying the platform is not a cheap pleasure.

The second feature is the longer the train, the higher the cost of its operation on the railway infrastructure.

World experience - two floors. The sample was taken by the German Deutsche Bahn and the Dutch NS. We decided to buy double-decker trains. Now the modern six-car Aeroexpress train has more seats than the first-generation ten-car, is serviced 6 times less, and the cost of its operation is much less.

We bought new trains, rented back to RZD. Now 7 ED4MKM-AERO and 11 ESH2 are owned. Of the two-story nine-carriage and two 4-carriage. Two-storyed go to Vnukovo and Domodedovo, but cannot in Sheremetyevo. Physically crawl through, but can not pass the tolerances of the approximation of buildings. This issue is now being discussed, it is necessary to slightly raise the contact wire on one of the overpasses.

A tender was announced, within the framework of which it was necessary to develop quite a lot of things according to the particular features of Aeroexpress taking into account operating experience and then produce, supply and service trains under warranty. Stadler (read Stadler), Škoda, and Alstom went to the final of the tender. There were applications from China and Korea, in particular, from Hyundai, but they had no experience in the construction of double-decker trains, that is, all development from the very beginning was supposed to be done on this project. And the rest of the finalists had the trains in operation, albeit not quite the same, but double-decker. As a result, Stadler defeated in terms of consumer qualities. Purchased 11 trains. That is, a modern two-story Aeroexpress is a very heavily modified Stadler KISS. A two-story building of this size from the same common ancestor runs in Azerbaijan and Georgia,

In 2012, there was a large-scale reconstruction of more than a billion rubles. It lasted two years - this is to serve double-decker trains. The reconstruction was sponsored entirely at the company's own expense. It turned out interesting. See:

See these yellow jacks?

These are not just jacks, this is an installation on 12 mobile columns. At the same time, the entire installation anywhere in the depot can lift three cars in a hitch. That is, to change the trolley on a six-car Aeroexpress, you do not need to disassemble the entire train. You can detach it exactly in half, raise half, do the work, put it back. By Russian standards, it is almost like a Formula 1 boxing in speed. Now Stadler is just changing the carts. By the way, in comparison with classical methods it is very fast, almost without decommissioning trains.

And this is the Koltech rail-mounted wheeled lathe. Needed for turning wheelsets, this is an important part of servicing any train so that the wheels are the same size after wear. In a metro depot, you usually need to take off pairs to serve. They are now considering the purchase of such machines. And here it’s enough just to put the train on top and start work.

A chip box is dialed in three days:

CPPK also puts its trains in this depot for service: this is because of quality and experience.

And here is the overpass:

Everything is so green because of the green LED strip at the contact busbar. The busbar in the depot is needed to service the whole train and check in all modes at the repair position. Previously, this was done in the park. And a garland is part of security. When green, there is no voltage on the contact wire. You can climb onto the roof and work. The voltage will not turn on if at least one door to the flyover is open. Then the red lights up.

Almost all the equipment of the new Aeroexpress is on the roof. The roof in the middle is smooth. Accordingly, staff should be nearby. This overpass extends fully to the train, handrails are pulled out.

That's what is served there. Climatic unit (there is air conditioning, air conditioning, UV lamp package and so on):

AFU:

U-shaped - this is a radio antenna:

Battery in the box:

Current collector:

Traction converter: The

same roof of the last generation and the past:

Height of past generations 4.6 meters , a new two-story - 5.2 meters.

The bottom of the car is smooth - it’s almost half the passenger compartment:

PSN, battery and other devices are assembled below us, at the end of the post there will be a link to examples from TVZ. But all the equipment here is arranged on top of the vestibules. Tamburas do not need a second floor. This is how it looks from the inside of the car:

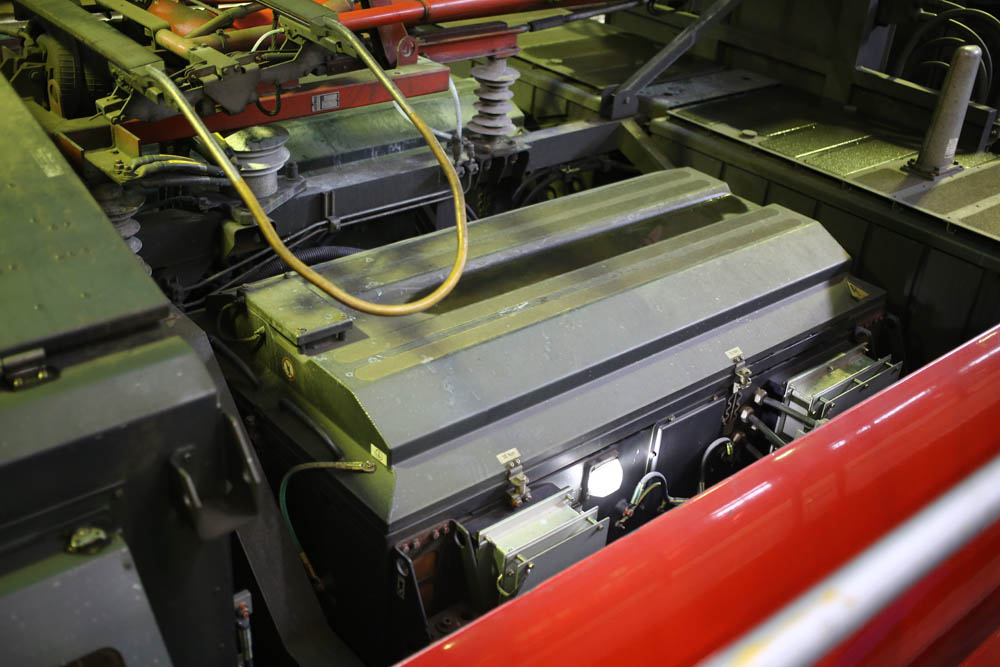

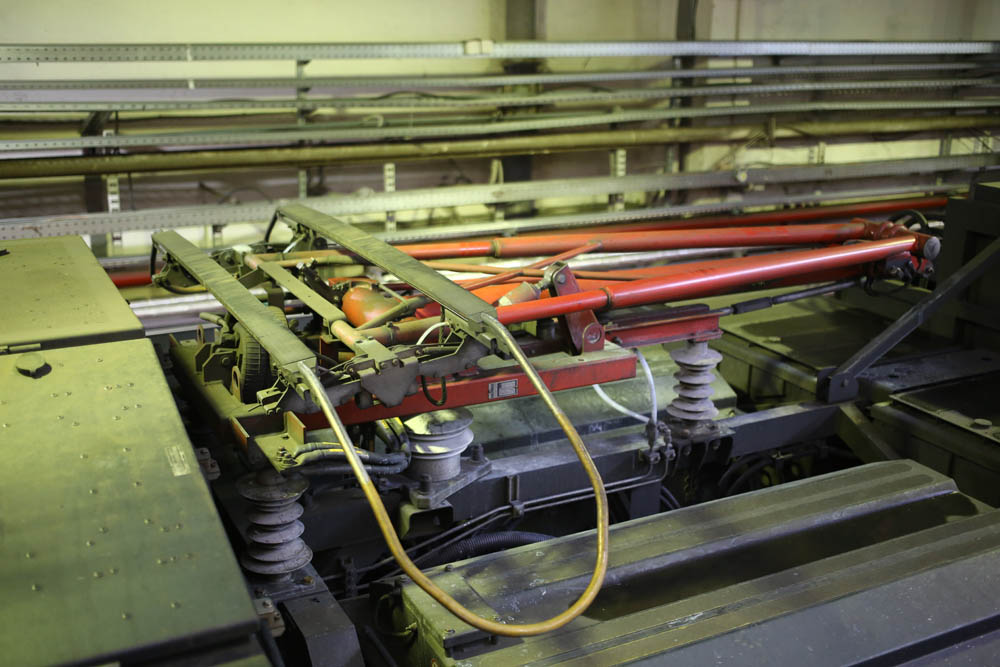

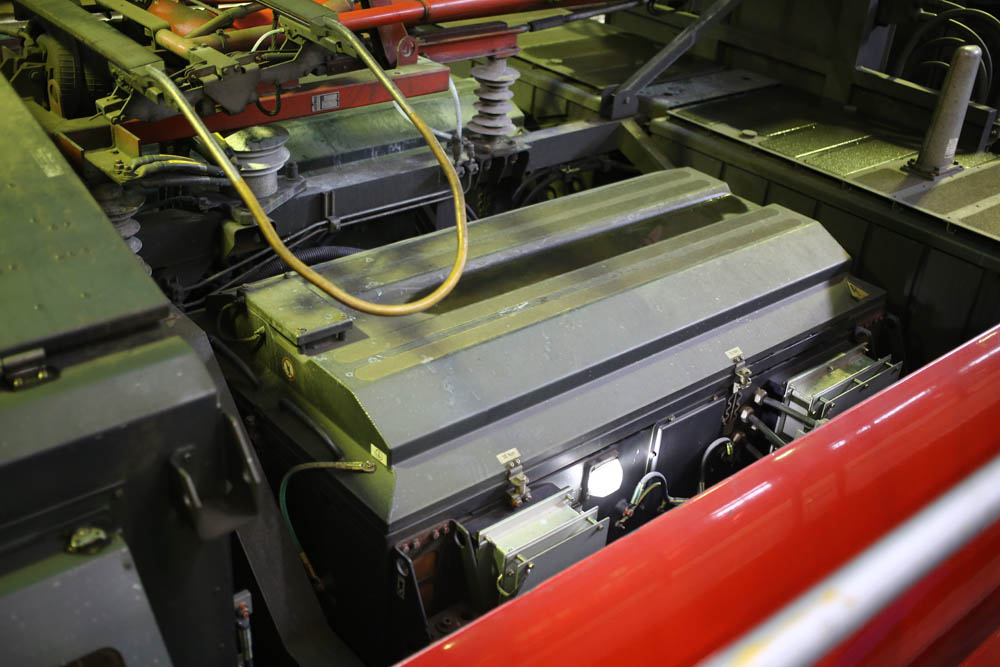

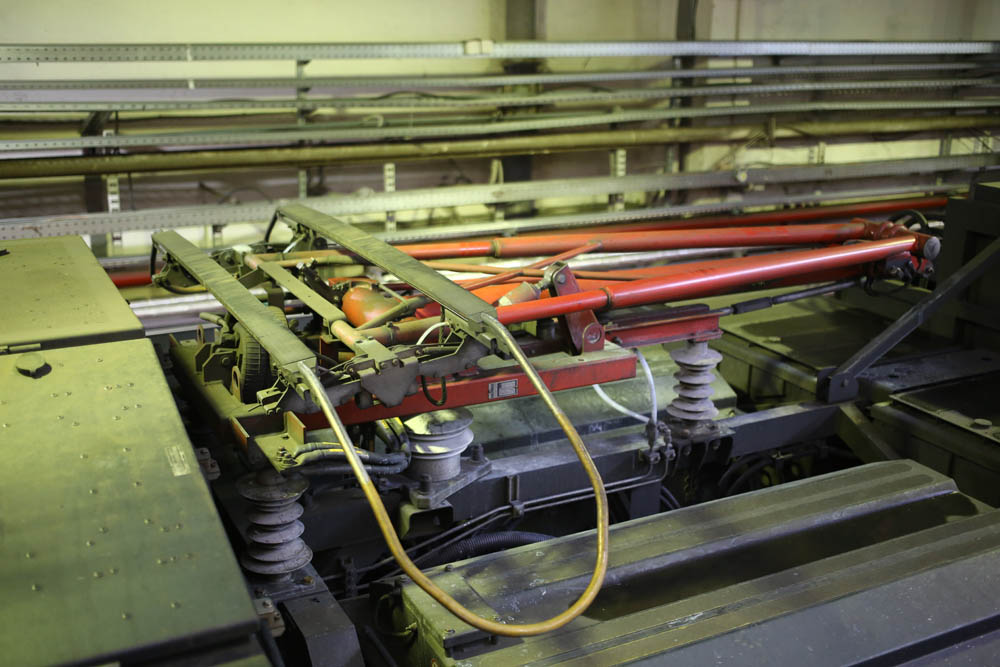

Much more compact. Here is the DC motor on the previous generation of Aeroexpress:

But it is three times smaller and twice as powerful on the new generation:

The new generation has an asynchronous drive, a new traction converter and many other technological wonders. Also compact and efficient.

Double clearance gapless hitch. External tight prevents new passengers from entering the train and protects the tracks from dust and moisture. And the inner vestibule is needed for the movement of passengers.

Pneumatic line from below, rigid, without sleeves:

Nearby, by the way, is 380V for shore supply of wagons (in particular, for diagnostic systems when parking):

From the inside it looks like this:

The most dangerous thing for a train is the tire on the tracks (sometimes children leave it). Because she jumps under the cars and disconnects the sleeves of the brake line. The train gets up. The driver always at the sight of an obstacle or danger applies emergency braking. So, here the highways are protected from such things.

Another part of the communications and equipment is hidden under the panel:

Doors are very thick, with double or triple sealing:

Business class, wide seats, plenty of space:

Built-in bar:

And wardrobe:

In general, the integration of different subsystems is a sore point. All these things must be considered at the time of designing the car so that they look like family. If suddenly after assembly it is necessary to hang fire sensors - they will mutilate everything. The new Aeroexpress was designed with all the features at once.

Here is the toilet, it is ordinary:

Here is the house-keeper:

Indirect stop crane:

Emergency stairs under the luggage racks:

They are needed in order to climb the compound roof somewhere off the beaten path if necessary. They are for evacuation through the window.

In the car there are up to 10 cameras, in the cab there is also a recorder and a camera for recording the actions of the driver.

This is a ramp between the platform and the car for people with disabilities. Here is the lift inside the car for passengers with reduced mobility:

And this is the toilet for passengers with

reduced mobility: The table reclines for changing. Behind it is a package of UV lamps for disinfecting the table (lamps burn when the table is closed):

The new one is much simpler than previous generations. There are about 150 people in the depot. To service 11 new trains, only 10-15 people out of these 150 are needed. The maintenance cycle is the same as before, 3-4 hours, but a new train arrives at the depot once a month, and not once every 6-8 days (with a run of 500 km per day). Here, look, Stadler changes pairs, and it is clear that the pads almost did not wear out during the year: A

double-glazed window is taken by one action, it is under this rubber band:

Current collectors with composite materials:

In the photo there is one that wears out in ice rain in a day. New ones are much better.

Driver. Now, at the time of the maneuvers on the depot, the driver’s place is serviced by an employee of the service team:

Armchairs are regulated:

There are cup holders:

If you lift the dashboard, there will be such beauty:

Well, the driver’s microwave and a kettle are nearby.

Like this:

Height - 1300 mm from the rail head.

And we go home along the green path: By the

way, it is safe only in the middle. For many years, under the USSR, car glass was repaired here, so glass fragments lie almost everywhere on the ground.

And we go to the platform of the Belorussky railway station:

Vadim Bakhitov, head of the production and technical department, was with us on the depot:

From today we sell Aeroexpress tickets to Tutu.ru, that is, when you buy a ticket, you can make another click and everything will be in one location and for one payment. Here it is:

And here are our posts about the railway: about the Trans-Siberian Railway , the Grand Express , what kind of trains are there , railroad power systems ,how passenger cars are arranged , how cars are assembled , how they evolved , about the Leningradsky station , about locomotives , about old cars . Great FAQ about long-distance trains and unobvious rules .

In this photo from the depot, three generations of electric trains are visible: the new double-decker train ESH2, the rather old ED4 (this was the first generation of express trains to the airport) and EG2T, which is “average” by characteristics between them is a good workhorse, which is also being repaired at the Aeroexpress depot.

Work in the driver's cab.

This is a very, very interesting example of a company on the infrastructure of Russian Railways.

What it is?

Aeroexpress is a comfortable electric train to the airports of the Moscow aviation hub (Vnukovo, Domodedovo and Sheremetyevo) from Kiev, Paveletsky and Belorussky stations from Moscow. A quick way to get from the city to the airport with a minimum of stops: from Domodedovo there is a stop on the transfer circuit of Verkhny Kotlov, and from Sheremetyevo - now to Okruzhnaya, and all this is past traffic jams. As elsewhere in the world, this method is more expensive than classic public transport, but cheaper than a taxi. According to international definitions, transportation is considered intermodal, since seamless transportation is the delivery of passengers from the hub to the hub (from the airport to the station).

How it all began?

In 2005-2007, the company only sold tickets. Rolling stock and everything connected with it was leased from Russian Railways. In 2008, the first own trains were purchased (which still run on the Sheremetyevo direction). Here is one of them for maintenance:

In 2011, the first own locomotive crew appeared, that is, in addition to trains, the Aeroexpress company began to operate.

In 2012, they took away the service for themselves, for which they took a long-term lease of an old depot near the Belorussky railway station, built in the 19th century for steam locomotives. Here is the turning circle:

What kind of depot?

The fan part is a depot built in the 19th century. Behind it is the already normal, more modern depot of the 1960 model of three steps (rooms). It is these three steps that Aeroexpress took and began to modernize.

Historically, this is a train depot. Each step was supposed to accommodate two steam locomotives on one ditch (from several ditches), that is, the length of the hulls was 72 meters per step. Then, due to new types of traction - diesel and electric - the depot was expanded. The first stage has remained unchanged. The second lengthened, to the part with arches completed the continuation. Here are the old arches:

The second step became 125 meters. The third step is the newest part, already 260 meters long, it was completed the longest. This is now the only depot in Moscow and the region with a workshop not of a straight line, but of a curved shape. This curved part was completed in 1975-1976 due to the development of suburban transport. Then suburban trains consisted of two cars, then - of six on an electric train of Riga production. Then complexity began to grow. Depot was built on 12 cars ER2 (now these trains are almost all written off). The Latvian plant, by the way, still makes components that are used in ED4, new EP2, and on the Orioles from the third number - also components of the Riga factory. Now Latvia makes the electric part, delivers car sets to the TVZ, and there they are assembled, commissioned, tested, and put into operation.

Shunting work is also carried out by the company on its own locomotives.

How did two-story Aeroexpresses appear?

In 2012, it became clear that passenger traffic would increase. Three years later, a new solution was needed. The traditional is to attach more wagons. But the estimated 12 cars did not fit on the platform, and modifying the platform is not a cheap pleasure.

The second feature is the longer the train, the higher the cost of its operation on the railway infrastructure.

World experience - two floors. The sample was taken by the German Deutsche Bahn and the Dutch NS. We decided to buy double-decker trains. Now the modern six-car Aeroexpress train has more seats than the first-generation ten-car, is serviced 6 times less, and the cost of its operation is much less.

We bought new trains, rented back to RZD. Now 7 ED4MKM-AERO and 11 ESH2 are owned. Of the two-story nine-carriage and two 4-carriage. Two-storyed go to Vnukovo and Domodedovo, but cannot in Sheremetyevo. Physically crawl through, but can not pass the tolerances of the approximation of buildings. This issue is now being discussed, it is necessary to slightly raise the contact wire on one of the overpasses.

How to choose a vendor for a double-decker train?

A tender was announced, within the framework of which it was necessary to develop quite a lot of things according to the particular features of Aeroexpress taking into account operating experience and then produce, supply and service trains under warranty. Stadler (read Stadler), Škoda, and Alstom went to the final of the tender. There were applications from China and Korea, in particular, from Hyundai, but they had no experience in the construction of double-decker trains, that is, all development from the very beginning was supposed to be done on this project. And the rest of the finalists had the trains in operation, albeit not quite the same, but double-decker. As a result, Stadler defeated in terms of consumer qualities. Purchased 11 trains. That is, a modern two-story Aeroexpress is a very heavily modified Stadler KISS. A two-story building of this size from the same common ancestor runs in Azerbaijan and Georgia,

We stopped at the depot ... What did we do there?

In 2012, there was a large-scale reconstruction of more than a billion rubles. It lasted two years - this is to serve double-decker trains. The reconstruction was sponsored entirely at the company's own expense. It turned out interesting. See:

See these yellow jacks?

These are not just jacks, this is an installation on 12 mobile columns. At the same time, the entire installation anywhere in the depot can lift three cars in a hitch. That is, to change the trolley on a six-car Aeroexpress, you do not need to disassemble the entire train. You can detach it exactly in half, raise half, do the work, put it back. By Russian standards, it is almost like a Formula 1 boxing in speed. Now Stadler is just changing the carts. By the way, in comparison with classical methods it is very fast, almost without decommissioning trains.

And this is the Koltech rail-mounted wheeled lathe. Needed for turning wheelsets, this is an important part of servicing any train so that the wheels are the same size after wear. In a metro depot, you usually need to take off pairs to serve. They are now considering the purchase of such machines. And here it’s enough just to put the train on top and start work.

A chip box is dialed in three days:

CPPK also puts its trains in this depot for service: this is because of quality and experience.

And here is the overpass:

Everything is so green because of the green LED strip at the contact busbar. The busbar in the depot is needed to service the whole train and check in all modes at the repair position. Previously, this was done in the park. And a garland is part of security. When green, there is no voltage on the contact wire. You can climb onto the roof and work. The voltage will not turn on if at least one door to the flyover is open. Then the red lights up.

And what is it on his roof?

Almost all the equipment of the new Aeroexpress is on the roof. The roof in the middle is smooth. Accordingly, staff should be nearby. This overpass extends fully to the train, handrails are pulled out.

That's what is served there. Climatic unit (there is air conditioning, air conditioning, UV lamp package and so on):

AFU:

U-shaped - this is a radio antenna:

Battery in the box:

Current collector:

Traction converter: The

same roof of the last generation and the past:

Height of past generations 4.6 meters , a new two-story - 5.2 meters.

So where is the second floor from?

The bottom of the car is smooth - it’s almost half the passenger compartment:

PSN, battery and other devices are assembled below us, at the end of the post there will be a link to examples from TVZ. But all the equipment here is arranged on top of the vestibules. Tamburas do not need a second floor. This is how it looks from the inside of the car:

Much more compact. Here is the DC motor on the previous generation of Aeroexpress:

But it is three times smaller and twice as powerful on the new generation:

The new generation has an asynchronous drive, a new traction converter and many other technological wonders. Also compact and efficient.

Where are all the wires and tracks?

Double clearance gapless hitch. External tight prevents new passengers from entering the train and protects the tracks from dust and moisture. And the inner vestibule is needed for the movement of passengers.

Pneumatic line from below, rigid, without sleeves:

Nearby, by the way, is 380V for shore supply of wagons (in particular, for diagnostic systems when parking):

From the inside it looks like this:

The most dangerous thing for a train is the tire on the tracks (sometimes children leave it). Because she jumps under the cars and disconnects the sleeves of the brake line. The train gets up. The driver always at the sight of an obstacle or danger applies emergency braking. So, here the highways are protected from such things.

Another part of the communications and equipment is hidden under the panel:

Doors are very thick, with double or triple sealing:

What's in the car?

Business class, wide seats, plenty of space:

Built-in bar:

And wardrobe:

In general, the integration of different subsystems is a sore point. All these things must be considered at the time of designing the car so that they look like family. If suddenly after assembly it is necessary to hang fire sensors - they will mutilate everything. The new Aeroexpress was designed with all the features at once.

Here is the toilet, it is ordinary:

Here is the house-keeper:

Indirect stop crane:

Emergency stairs under the luggage racks:

They are needed in order to climb the compound roof somewhere off the beaten path if necessary. They are for evacuation through the window.

In the car there are up to 10 cameras, in the cab there is also a recorder and a camera for recording the actions of the driver.

This is a ramp between the platform and the car for people with disabilities. Here is the lift inside the car for passengers with reduced mobility:

And this is the toilet for passengers with

reduced mobility: The table reclines for changing. Behind it is a package of UV lamps for disinfecting the table (lamps burn when the table is closed):

How is the train served?

The new one is much simpler than previous generations. There are about 150 people in the depot. To service 11 new trains, only 10-15 people out of these 150 are needed. The maintenance cycle is the same as before, 3-4 hours, but a new train arrives at the depot once a month, and not once every 6-8 days (with a run of 500 km per day). Here, look, Stadler changes pairs, and it is clear that the pads almost did not wear out during the year: A

double-glazed window is taken by one action, it is under this rubber band:

Current collectors with composite materials:

In the photo there is one that wears out in ice rain in a day. New ones are much better.

What's in the cockpit?

Driver. Now, at the time of the maneuvers on the depot, the driver’s place is serviced by an employee of the service team:

Armchairs are regulated:

There are cup holders:

If you lift the dashboard, there will be such beauty:

Well, the driver’s microwave and a kettle are nearby.

We leave the cab!

Like this:

Height - 1300 mm from the rail head.

And we go home along the green path: By the

way, it is safe only in the middle. For many years, under the USSR, car glass was repaired here, so glass fragments lie almost everywhere on the ground.

And we go to the platform of the Belorussky railway station:

Vadim Bakhitov, head of the production and technical department, was with us on the depot:

From today we sell Aeroexpress tickets to Tutu.ru, that is, when you buy a ticket, you can make another click and everything will be in one location and for one payment. Here it is:

And here are our posts about the railway: about the Trans-Siberian Railway , the Grand Express , what kind of trains are there , railroad power systems ,how passenger cars are arranged , how cars are assembled , how they evolved , about the Leningradsky station , about locomotives , about old cars . Great FAQ about long-distance trains and unobvious rules .