Axial internal combustion engines

Axial ICE Duke Engine

We are used to the classic design of internal combustion engines, which, in fact, has been around for a century. The rapid combustion of the combustible mixture inside the cylinder leads to an increase in pressure that pushes the piston. That, in turn, turns the shaft through the connecting rod and crank.

Classic ICE

If we want to make the engine more powerful, first of all we need to increase the volume of the combustion chamber. By increasing the diameter, we increase the weight of the pistons, which negatively affects the result. By increasing the length, we lengthen the connecting rod, and increase the entire engine as a whole. Or you can add cylinders - which, of course, also increases the resulting engine capacity.

Engineer ICE for the first aircraft faced such problems. They finally came to a beautiful “star-shaped” engine design, where the pistons and cylinders are arranged in a circle relative to the shaft through equal angles. Such a system is well cooled by air flow, but it is very dimensional. Therefore, the search for solutions continued.

In 1911, the Macomber Rotary Engine Company from Los Angeles introduced the first of the axial (axial) ICEs . They are also called "barrel", engines with a swinging (or oblique) washer. The original scheme allows you to place pistons and cylinders around the main shaft and parallel to it. The rotation of the shaft occurs due to the swinging washer, on which the piston rods are pressed alternately.

The Macomber engine had 7 cylinders. The manufacturer claimed that the engine was able to operate at speeds from 150 to 1500 rpm. At the same time, at 1000 rpm, he gave out 50 hp. Being made of materials available at that time, it weighed 100 kg and had dimensions of 710 × 480 mm. Such an engine was installed in the aircraft of the pioneer aviator Charles Francis Walsh “Walsh Silver Dart”. Soviet engineers

did not stand aside . In 1916, the engine of the design of A. A. Mikulin and B. S. Stechkin appeared, and in 1924, the Starostin engine. Perhaps, only fans of the history of aviation know about these engines. It is known that detailed tests carried out in 1924 revealed increased friction losses and large loads on individual elements of such engines.

Starostin’s engine from the Monino Aviation Museum A

brilliant and slightly insane engineer, inventor, designer and businessman John Zachariah Delorean dreamed of building a new automobile empire in spite of the existing one and making a completely unique “dream car”. We all know the DMC-12, which is simply called DeLorean. She not only became the star of the screen in the film "Back to the Future", but also was distinguished by unique solutions in everything - from the aluminum body on the Plexiglass frame to the doors “wings of a seagull”. Unfortunately, amid the economic crisis, machine production has not paid off. And then Delorean sued for a long time in a fake drug case.

But few people know that Delorean wanted to supplement the unique appearance of the machine with a unique motor - among the drawings found after his death there were also drawings of the axial ICE. Judging by his letters, he conceived such an engine back in 1954, and seriously set to work on development in 1979. There were three pistons in the Delorean engine, and they were located in an equilateral triangle around the shaft. But each piston was two-sided - each of the ends of the piston had to work in its own cylinder.

Drawing from Delorean's notebook

For some reason, the birth of the engine did not take place - perhaps because the development of a car from scratch turned out to be a rather complicated enterprise. On the DMC-12 installed a 2.8-liter V6 engine jointly developed by Peugeot, Renault and Volvo with a capacity of 130 liters. from. An inquisitive reader can study scans of drawings and notes of Delorean on this page .

The exotic version of the axial engine is the “Demand engine”

Nevertheless, such engines were not widely used - in large aviation, the transition to turbojet engines gradually took place, and in automobiles to this day a scheme is used in which the shaft is perpendicular to the cylinders. It is only interesting why such a scheme did not take root in motorcycles, where compactness would come in handy. Apparently, they could not offer any significant benefits compared to the usual design. Now these engines exist, but are installed mainly in torpedoes - due to how well they fit into the cylinder.

Option called " Cylindrical Energy Module " with double-sided pistons. Perpendicular rods in the pistons describe a sinusoid moving along a wavy surface

The main distinguishing feature of the axial internal combustion engine is compactness. In addition, its ability to change the degree of compression (volume of the combustion chamber) simply by changing the angle of inclination of the washer. The washer sways on the shaft thanks to a spherical bearing.

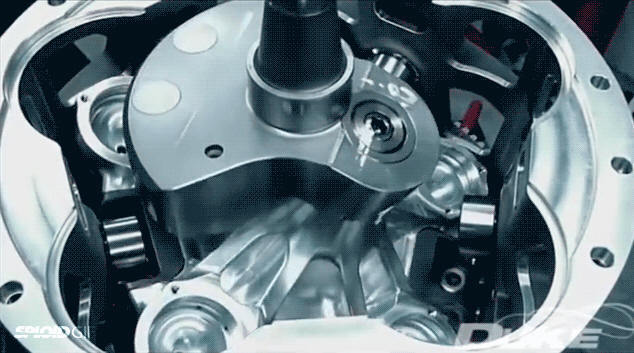

However, the New Zealand company Duke Engines in 2013 introduced its modern version of the axial engine. There are five cylinders in their unit, but only three nozzles for fuel injection and - not a single valve. Another interesting feature of the engine is the fact that the shaft and washer rotate in opposite directions.

Not only the washer and shaft rotate inside the engine, but also a set of cylinders with pistons. Thanks to this, it was possible to get rid of the valve system - the moving cylinder at the moment of ignition simply passes by the hole where the fuel is injected and where the spark plug is. At the exhaust stage, the cylinder passes the gas outlet.

Thanks to such a system, the number of required candles and nozzles is less than the number of cylinders. And one revolution accounts for a total of as many piston strokes as a conventional design 6-cylinder engine. At the same time, the weight of the axial motor is 30% less.

In addition, engineers from Duke Engines argue that the compression ratio of their engine is superior to conventional counterparts and is 15: 1 for the 91st gasoline (in standard automotive ICEs this indicator is usually 11: 1). All these indicators can lead to a decrease in fuel consumption, and, as a result, to a decrease in harmful effects on the environment (well, or to an increase in engine power, depending on your goals).

Now the company is bringing the engines to commercial use. In our age of proven technologies, diversification, economies of scale, etc. it's hard to imagine how you can seriously affect the industry. In Duke Engines, apparently, they also represent this, therefore they intend to offer their engines for motor boats, generators and small aircraft.

Demonstration of small vibrations of the Duke engine