To the question of strangeness and impossible

An engineer should not waste time saying “This cannot be,” as this has already happened. He should look for the objective cause of what is happening.Unfortunately, I could not find the exact quote, so you see it in my interpretation.

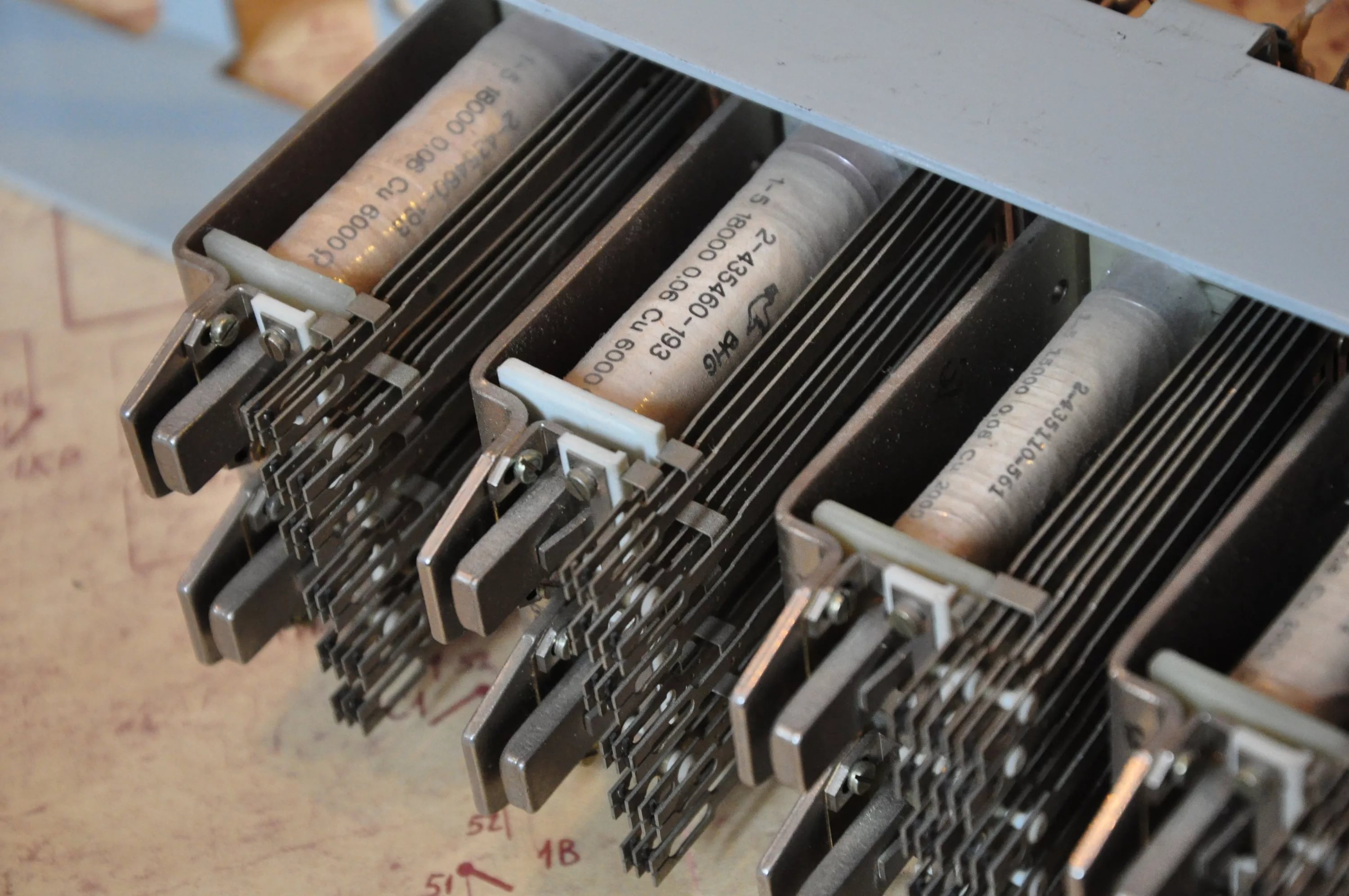

We continue the story of interesting defects in the field of electronics. Today we will talk about the "industrial" network in the telephone exchange (depicted on the KDPV) based on the RS485 interface.

Further in the story abbreviations will be actively used, but there is no need to be scared, their decryption will be given in brackets, so welcome to cat.

A long time ago (about 8 years ago), when I was doing business in the field of communications in the Tver Region, I was able to implement (in some way, for that time) the revolutionary idea of modernizing the existing ATSK100 / 2000 (Automatic Telephone Exchange Coordinate) based on the existing me by the time of the development of ATSE (Electronic). By the way, I still remember a trip to the department of the Ministry of Communications, where his representative was perplexed: “Why would we spend money (at the rate of $ 10 per room) on upgrading the station, which we will replace with a digital one (at the cost of 70+ $ at two number) ”(in brackets are my explanations). Using third-party resources, the department's resistance was overcome and modernization was carried out. 8+ years have passed since then, the modernized station is functioning quite successfully for itself,

So, an integral part of the project was the replacement of the checkpoint (Code Receiver-Transmitter) located within the AIS (Case of Subscriber Searches) with their electronic version, which, in addition to the main functions, had to exchange information on the state of AK boards (Subscriber board) with the main BE (Block Electronic) kit). So, a communication channel was required, which was supposed to work in automatic telephone exchanges, and these are rows of iron cabinet cabinets in which the relay is constantly switched by inductance to Henry units at a voltage of 60 volts.

- this is so that you understand that I was not mistaken in writing the inductance rating.

For someone who is in the subject, everything is clear, I will explain to the rest that under such conditions the noise situation in the station room is very tense. There was no talk of wireless communication right away, but not much of the wired options - a serial interface either in the form of a current loop or in the form of 422/485. Since it was necessary to connect one main unit with 13 (10 + 3) gearboxes, a point-to-multipoint connection was needed, so that the current loop went off the track. It’s a pity, according to my observations, that a correctly designed current loop has no equal in terms of noise immunity, but there is nothing to be done, the one-to-many topology is not a strong point of this technology.

It is also necessary to take into account the design features of the station - the entire installation of connections (and there are a lot of them in the telephone exchange) is carried out using cable-rails above the cabinets (2.5 meters high, by the way) - a horizontal blue line on the KDPV, and the replaceable gearbox is located at the bottom of the cabinet (vertical blue line in the same place), and this is not subject to change. Note that you do not see the checkpoint in the picture, it is located on the back of the cabinet where the ISS are located, I did not find the photo on the right side, but it is located exactly below. This circumstance should be taken into account when designing the network from the point of view of the design features of the connecting cable. The choice between 422 and 485 was not difficult - the work protocol allows for the simplex method, so 485 is quite acceptable, and it has fewer wires.

Next, the UART-RS485 converter is installed on the electronic transmission, the type of cable for communication is selected - FC10 (I actively used it in other projects and it is quite convenient to install, and it is decent wave), given the desirability of a sequential bypass of nodes in the topology, 2 connectors are installed on the electronic transmission - input and output. Devices are manufactured, mounted on automatic telephone exchanges, operate autonomously, and the installation of a communication network must begin.

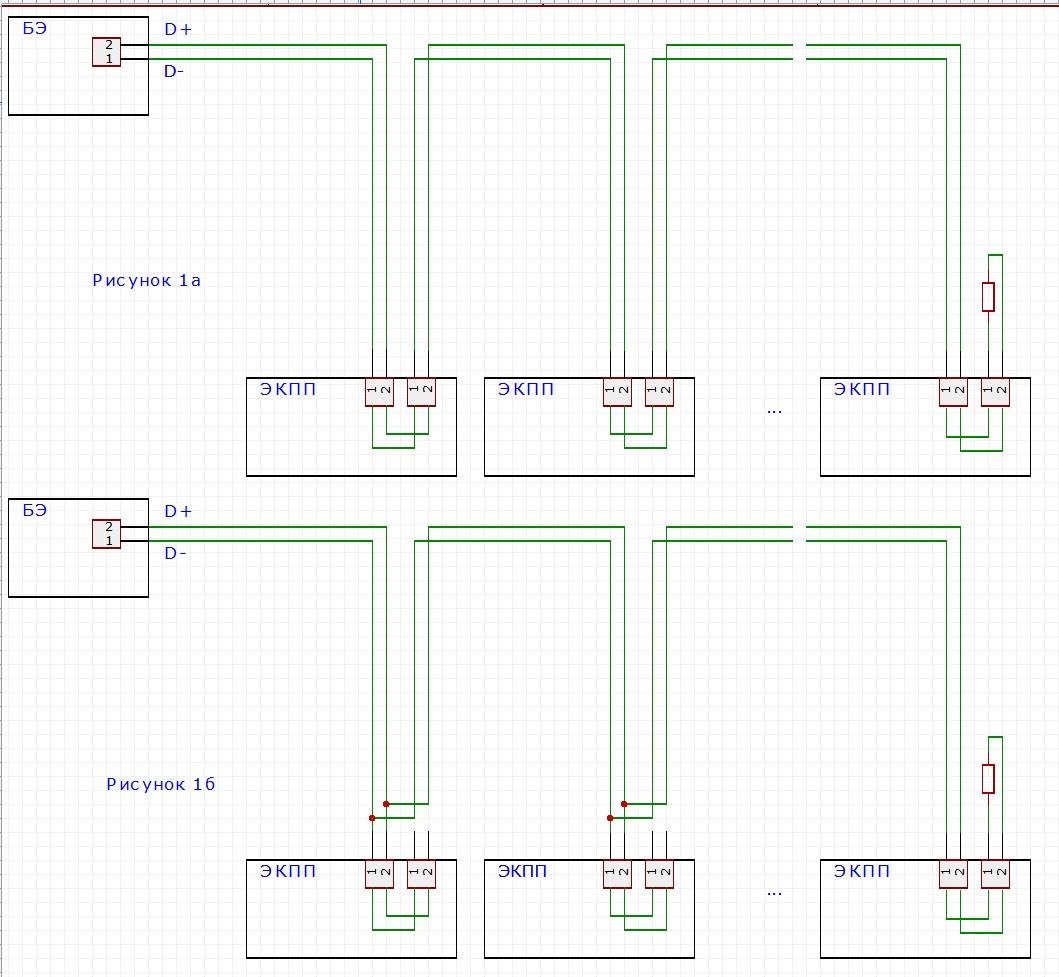

The sequential traversal topology, shown in Figure 1a) was originally planned, but its drawbacks are obvious at first glance - the vulnerability to deleting a node. The parallel cable connection option shown in Figure 1b) is no better, since the cable will have to be mounted “in place” and there will be problems if there is a need for repair, and installing two cables on one connector (for this type of cable and connector) is not possible call a convenient solution.

Therefore, we come to the option with bends. Yes, I know that this option is not recommended for use and I understand perfectly why this is done, but this is just a wish, and not a categorical imperative. Therefore, taking into account that:

0) the network as a whole is not too long (each branch is 20 meters);

1) the bends are not too long (about 2 meters);

2) the speed is not too high (I don’t remember the exact number now, no more than 115200 baud, and maybe even 9600);

3) good converters with high noise immunity (AD);

4) a bunch of lands has been dragged in the cable (in general, all the checkpoints are connected through a common plus - telephony has power supply with a grounded plus, but you can’t spoil the porridge with oil),

we conclude that you can try.

We make the experimental section, shown in Figure 2, check the waveform of the oscilloscope (the arrow does not rotate), start the exchange test (the TS (network tester) was developed and manufactured in advance, which checks the exchange with each automatic transmission in the network segment) and we don’t see any failure - all this means that we were lucky (although this luck was carefully prepared) and convenient installation did not lead to bad signals.

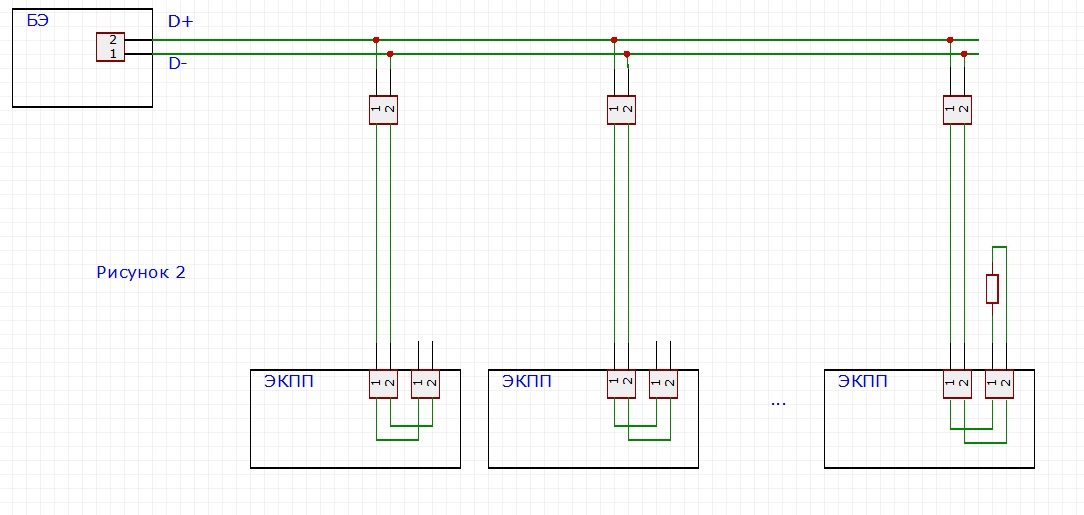

So far, we see a success story, and here comes the confusion. Inspired, we collect the remaining network segments and (not to lose the goodness) check them using the aforementioned tester. In the process, we find that the exchange with the second automatic transmission fails (Figure 3a), and at all (that is, never), and everything is fine with the rest.

We put forward the assumption that the cable reduction segment or EPC is to blame, we check according to scheme 3b) (in general, a completely redundant check, just to not go far) - the assumption is confirmed, the final touch is scheme 3c) and a sudden bummer - everything works, so it’s not a cable . We assume that the checkpoints are to blame, but we checked them after assembly, all right, it happens, we swap 2 neighboring checkpoints in places (it’s easy to do this) and we are surprised to see that the defect remains in place, which means that the checkpoint is not to blame. That is, this is still a reduction segment, we swap two adjacent cable segments in places and (Bingo!) The defect moves after the cable. Very good, but how to explain the test results c) (I remind you that everything worked) with a possible cable defect is not clear.

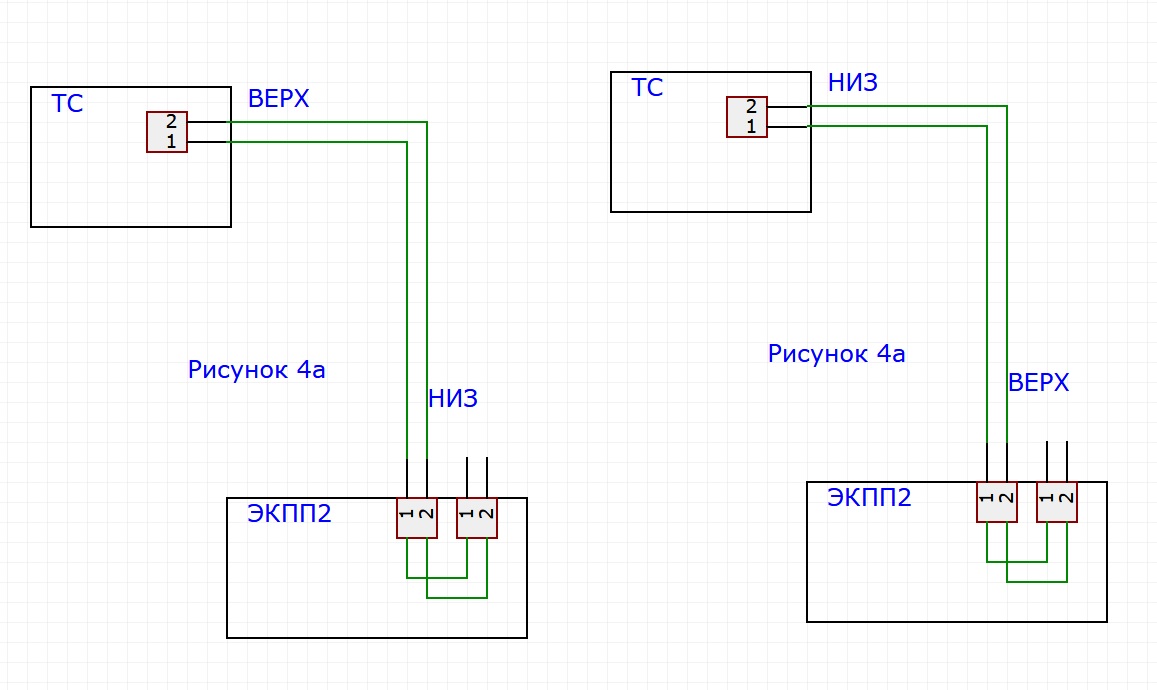

We isolate the suspicious cable segment and test it specifically - Figure 4 a) and b) and quite expectedly we get that the first option does not work, but the second (this is when we deployed the cable upside down) suddenly (but also already expected) quite It’s functioning.

But it can't be like that! - but it is - it means that I just don’t understand something. We formulate what exactly cannot be - that two identical devices behave differently at two identical ends of the cable. But two different devices at different ends of the cable can behave differently - we will look in this direction.

So the first question is - do I have the same devices? And it turns out that no - the terminating resistor is on the tester (along with the pull-up resistors), and on the checkpoint this block is installed only at the far end of the network. I take the terminator from the last device, put it on the current gearbox and everything starts working with any cable orientation, that is, at both ends of the cable segment. The first misunderstanding has disappeared, the devices are really different, I remove the terminator and continue research.

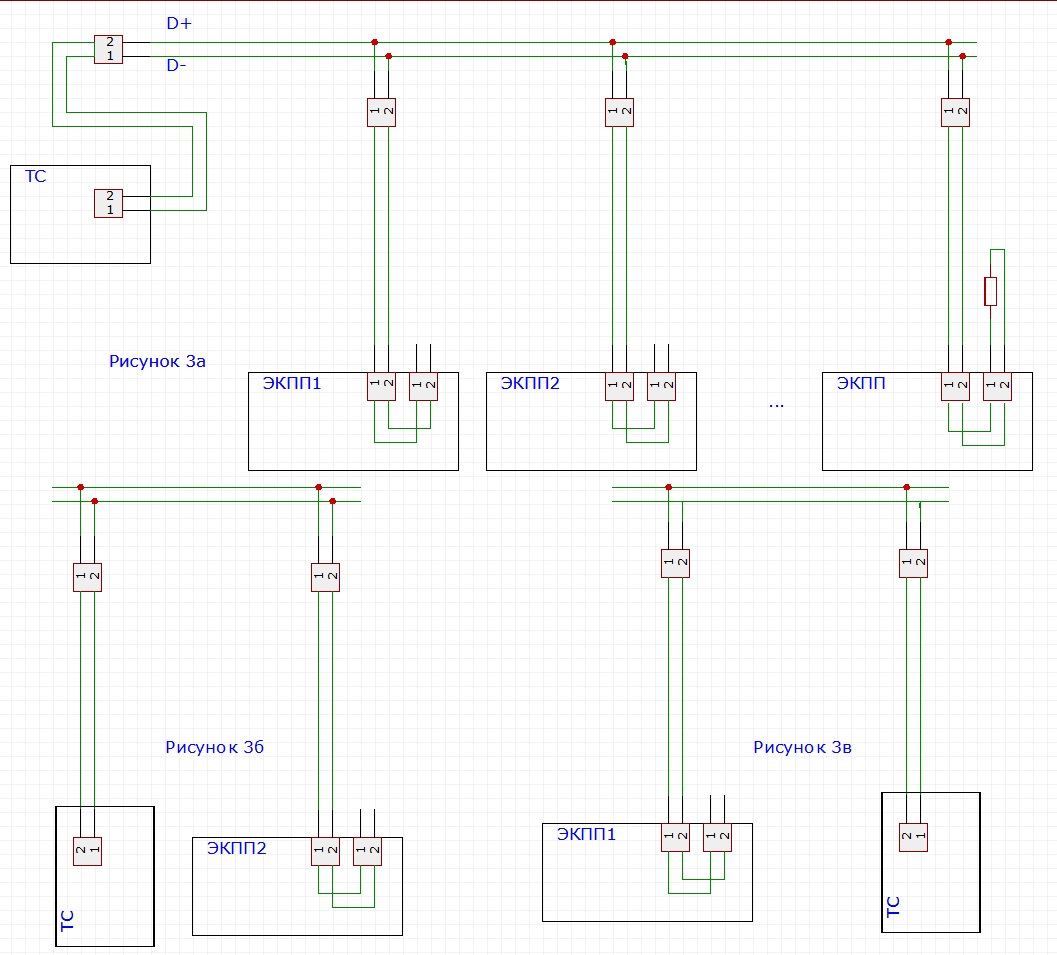

Now you need to understand how the ends of the cable segment differ. Again, at first glance, this is impossible, because we only have 2 wires for both receiving and transmitting (in fact, there is also a third wire - attracting lands, but it cannot influence so fatally), and they cannot stop working when to the cable turn - the wire either is from one end to the other, or it does not exist at all. But there should be a difference - we take the cable and carefully look at it. And here comes the moment of truth.

As I indicated earlier, a flat cable with 10 wires was chosen for installation (no longer needed, but I didn’t have less, yes, maybe it never happens at all). And it is necessary to conduct only 3 signals, there are extra wires. We, the signalmen, know for sure that “pair per core” (using two parallel-connected wires instead of one) is a good practice, since it reduces the resistance of the circuit section and improves the reliability of operation, this technique was also applied for this case. Each of the signals was transmitted through two wires of the cable and the present circuit does not look a bit like I painted it before - see Figure 5a).

Then the cable segment may have a defect, shown in 5b) and if there is a connection, in principle (due to a faulty core), the cable has different ends (due to a faulty core).

Well, now everything is simple. An unconnected wire, on the other hand, works as an antenna, collecting interference, which, if there is a terminator (and extensions), is suppressed, and if they are absent, they affect the receiver and disrupt the protocol. We call the cable segment and find out that, indeed, the edge connector did not pierce one of the wires of the data line (the connector is mounted on the cable with a pin - a very convenient and quick operation that does not require preparation of the wire and is performed “at a time”, but, as it turned out, requiring control). You can ask a question - why did the receiver not remove the interference, because the RS485 interface is differential and should be insensitive to common mode interference. The answer lies precisely in the nature of the defect - transverse asymmetry of the cable occurs, which dramatically increases the sensitivity to common-mode interference.

Further, in order to detect such defects in the test device, a revision was introduced that allowed using the switch to work with one of the wires of the data pair and all previously mounted sections of the communication network were checked, which made it possible to detect two more defects of this kind that did not lead to malfunction.

Here is such an instructive story, fully justifying the epigraph to the post.

Only registered users can participate in the survey. Please come in.

Traditional poll at the end of the post

- 39.2% need more stories about iron, because it is the most mysterious 33

- 5.9% need more stories about software, because it is often buggy 5

- 65.4% of “one and the other, and you can without bread” 55

- 13% need more cats 11

- 5.9% I do not understand, this is not the place Habré 5