How to milk cows with robots and make an industrial startup on this. R-SEPT development history

In 2017, the media sounded a very interesting story about a startup that robots milking cows on industrial dairy farms. The company is called R-SEPT, and then it received 10 million rubles of investments. But a year has passed, and there is no news of what happened next. We caught up with Alex Hahunovym ( AlexeiHahunov ), the founder of a startup and talked about the development. It turns out the whole year his team brought the prototype of the robot to mind, and just a week ago, conducted the first field tests on the farm.

Under the cut, the story is like a robotics student who grew up on a parent farm, turned a university degree into an industrial startup, as the first manipulators gathered with friends, and then went out to the level of state programs on agricultural robotization. And the most important thing is that the iron arm of a robot and machine vision are better than a live milkmaid.

Alexey Khakhunov

This week we put the robot on the farm and milked the first cow for them. Everything went quite fun. Our family has a dairy enterprise where I worked before. It is located in the Sergiev Posad district, the village Kuzmino. We have one and a half thousand cows there. This is a large enterprise.

I got a degree in robotics. Naturally, itching to use theoretical knowledge in battle. I looked at how things work with robotization in the dairy sector, and came to an interesting conclusion. All existing robots - and now there are three main producers - were created in Europe, and the markets of America or Russia are very different from it. In Europe, small family farms are common, up to 200 cows. In Russia, China and America - very large. We have an enterprise where there are about 50 thousand cows. At the same time, in Europe, 40% of farms are robotized, and in other markets, robotization does not exceed one percent. And the problem is that the robots that were made for small farms were not adapted to the realities of big ones.

In Europe, the farmer milks, feeds and does everything. The cow should be milked for the first time at five or six in the morning. This is a difficult process - really difficult. To relieve the pain of the farmer, he invented a robot that helps to cope with it, but economically does not give any benefit. He just needed to make it easier for the farmer to live. And large enterprises are needed to make a profit. The cost of the robot, performance, maintainability and other things must meet large numbers of industrial standards.

Virtually all existing robots come up with vets. They knew very well how to work with a cow, but many of the constructions they got were not perfect, redundant and had many obvious flaws.

We decided to create an industrial-grade robot, which will be cheaper than the existing ones, but it will contain the latest technologies from the field of robotics and take into account all the experience of working with a cow. The goal is - it remains to implement.

Milking robot

According to modern practices on the farms, cows do not have a certain fixed place - just a hundred or two hundred cows walk around the yard, can lie in any stall, eat at any time. The robot is put in the same cycle, and the cow comes there itself.

The diet of the cow consists of a very large number of components. But the most pleasant for her is the feed. It is like sweetness to a person. To drive a cow into a robot, she is not given feed at the usual time, but is given only in a robot, and she comes there to feast on food. While we did not do this, the cows did not have a normal motivation to come to milk. They were stressed out.

A robot is essentially a single closed stall. It has two doors. One opens when the cow goes out, the other starts the next cow and closes.

There is one myth that people love to tell: supposedly the cow loves to be milked by the milkmaids. To be stroked, loved - and only then she will give a lot of milk. In fact, this is absolute bullshit. The only thing that loves a cow is the absence of stress and absolute repeatability. If a cow is fed the same ration every day, the same time is given the same amount of water, the same amount of water is given and it is desirable to maintain the same temperature, and there are no loud noises around, then the cow will give the maximum amount of milk because she is comfortable. As soon as any external factor appears, there will be less milk. The trick of the robots is that they are absolutely identical, from time to time, perform all operations.

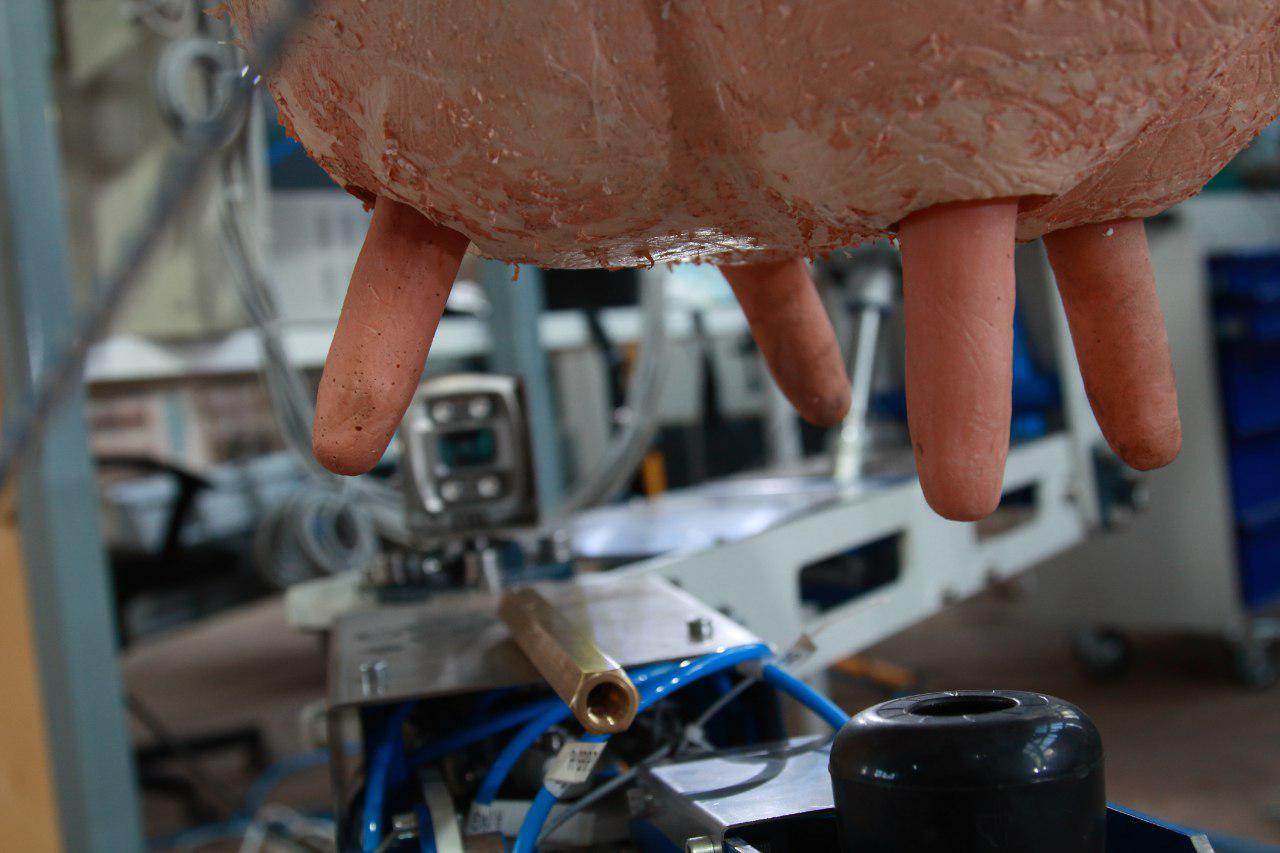

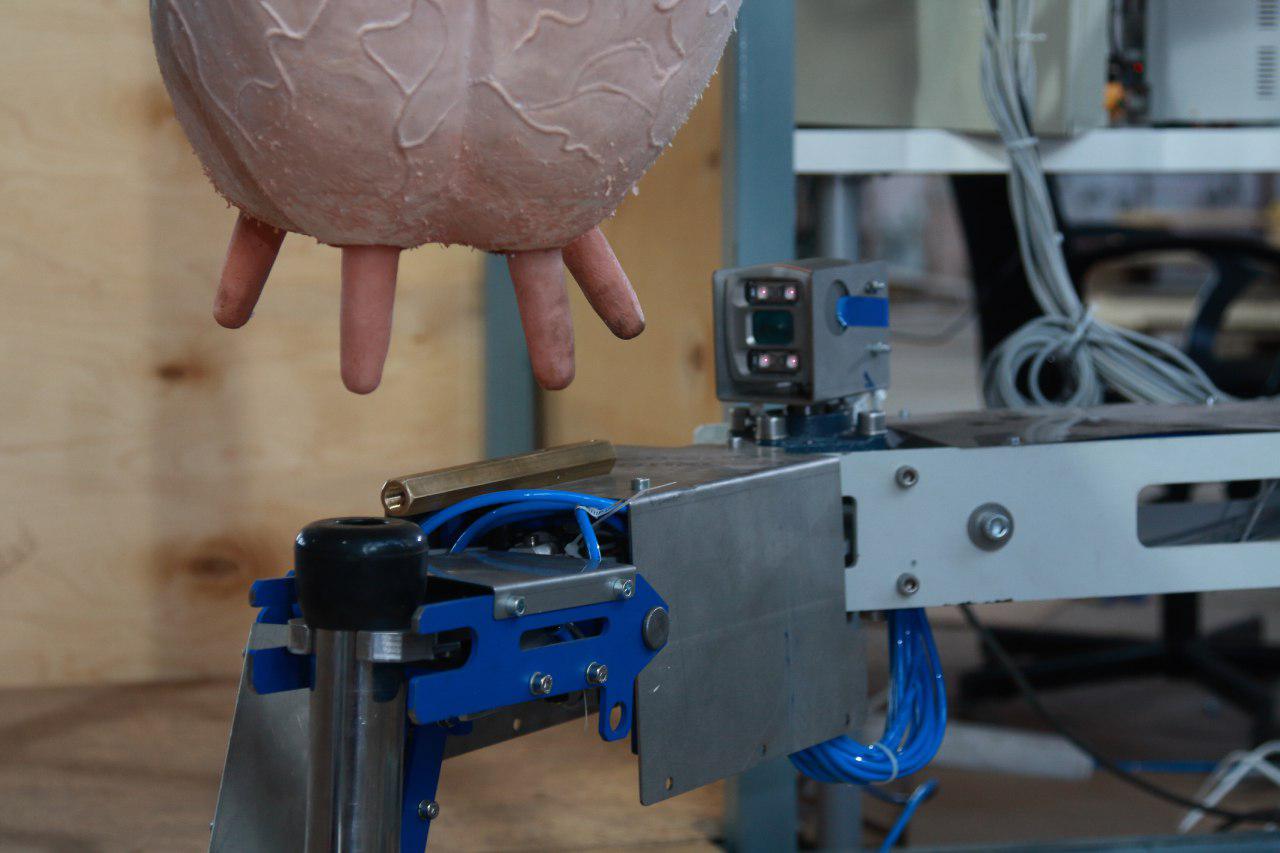

The cow comes in, she is given food. Under the cow is placed arm-manipulator. There is a teat cup. First, it is cleaned, then the first streaks are done, so that the cow starts the hormonal process of milk release. These streams are analyzed - whether the cow has any diseases, everything is in order with her. After half a minute the process of milking begins.

The hand takes the teat cups, brings them to the teats of the udder. Inside there is a heart rate monitor, which with a certain frequency turns on and off the negative pressure. And the milk starts to suck.

There is a sensor that checks occupancy. When the milk supply falls, it means the cow has gone up. The teat cup is turned off and a special solution is applied to the udder that “closes” the udder. After milking the cows open the milk channel, and it is impossible for an infection to get there. The solution with iodine preserves it.

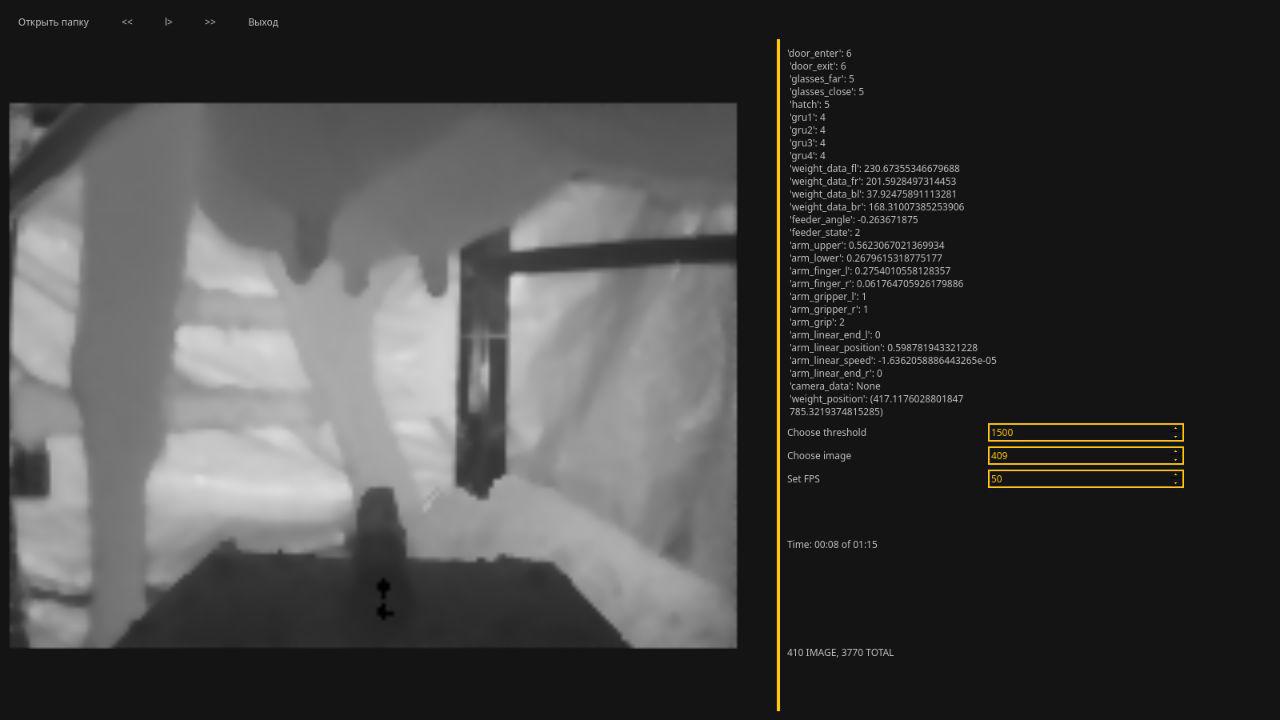

Nobody controls the robot, he lives his life. He knows where the glasses are - they are always in one place. Further computer vision works. The robot has a camera that receives a three-dimensional image with a high frequency. Algorithm is looking for in the picture, where the nipples.

All pictures are in grayscale - no colors, just a spectrum from black to white. The camera 30 times a second shoots what is happening around itself with a fairly low resolution - 420 by 340. At the first stage, we simply planted people who marked where the udder nipples are in the picture. First, the whole nipple was segmented, then where the most extreme low points are located.

We had to collect a lot of data - we shot several thousand cows. At first, we used convolutional networks for volumetric images, but convolutions were very hard to learn from them - a huge amount of data was needed. Therefore, they were transferred to the standard detection on a flat image, and they took PyTorch as a framework.

Development history

My parents were veterinarians, and for a long time they simply worked on the collective farm. At first, my father was offered to become the deputy director of the enterprise, and then head the enterprise next door, develop it. Our family has a joke that a collective farmer is not a profession, but a state of mind. From March to October, work begins at five in the morning and does not end until nine in the evening. It's very hard. Something is happening around the clock.

Agriculture is an ambiguous industry, and not to say that it is strongly monetary. I did not see myself as a farmer. When my brother and I traveled to different enterprises in Europe and analyzed robots, I was surprised by their story about generations. Especially funny when they said: “I have been managing this enterprise for 13 years after my father. We are growing very well. We had 60 cows - and it became 70. We are developing! ”When my father took the enterprise in the two thousandths, there were a hundred cows there. Now there are one and a half thousand of them, and everyone doubts whether this is sufficient growth.

I studied in one of the top physical schools in the Moscow region, in the Sergievo-Posad district, and I definitely should have become a techie. I liked programming a lot. The main languages in physics and mathematics were Pascal and Delphi, and I knew a little C ++. Now I don’t understand how, but we managed to do a lot of interesting things in Pascal. In the ninth grade, the teacher told us: "I forbid you to play games in the classroom, only if you do not write them yourself." And we wrote a few for the year. At first they made their own snake, then tanchiki, and they could play on the grid.

I had several olympiads written for entering the university: MIPT, Baumanka. I could go anywhere, I could only choose. Opened lists of all specialties that are in universities, read, and I became incredibly boring. I didn’t want to do some fundamental things, I wanted something more practice-oriented. The choice gradually fell on Baumanka, instead of MFTI or MSU.

Robotics seemed to be the perfect combination - you create something physical, but you can write code and see how it exists in the real world. Unfortunately, we have a fairly weak education in robotics. It does not work at the system level. When they give you a list of references, no book is dated to the 21st century, it is very demotivating. We were taught to design, solve problems for termehu and sopromat. But real robotics had to be taught by ourselves.

When we did diplomas, I decided that writing a regular one is boring, and I have to choose something that can be used later. At this point in the last year, we began our project. After the defense, they even gathered a small team of friends. Someone was engaged in circuitry, someone programming. We gathered in a handful of specialties and began to make the first version.

Inspired by the ideas from the books, they decided that it was necessary to rent a house somewhere outside of Moscow and to live and work there all summer. It was a terrible idea! Six guys who live in the same place do not very well monitor what is happening around, but they really work a lot.

It was a hotbed ... just in a row. I remember a funny moment when vape gained popularity. You open a room where two developers are sitting, and there is nothing visible, just nothing! You come and think, and here in general there are people?

During this summer, we made the very first sketches of the manipulator. We made some first details - we just collected the drawings and ordered them in production. Of course, they made a million mistakes - we used to have very inexperienced designers. Now we have found a class specialist in robotics, and began to move from a garage initiative group to a company whose product meets industrial standards and modern requirements of robotics.

Inside the project, we even do very low-level things on our own, because everything has its own specifics and the existing products do not suit us. In order to milk a cow, we cannot use the existing standard industrial 6-degree manipulators. They are redundant for our design and are very expensive. We now have four degrees of freedom. And it is ten times cheaper than any industrial manipulator.

All circuit design with low-level programming, all microprocessors, the entire design and software part we write independently. We do not manufacture sensors, engines and other similar things.

Feeding robots, carousels and machine learning rations

When we started to dive harder, we realized that it’s impossible to cover all the needs of the farm with a single milking robot. Therefore added two more products.

Feedpusher

When the cows are laid out feed on the farm, they eat through the headholder — they stick their heads forward — to where their feed is scattered. But according to their physiology, they constantly push it aside and stop getting it, because the headholder limits their movements. It turns out they have a meter of food - they eat 30-40 cm, and another 60 out of reach is within reach.

Usually a person walks with a snow shovel and moves everything backwards. But a person tends to forget, be lazy, do badly. The cow starts to eat less at this moment - this is bad. To do this, and came up with this type of robot.

But again, most were created in Europe. There, they are designed to work all in one yard or in one room. In large enterprises, there are many courtyards, usually three to five large farms standing next to each other, united in different ways. Feedpusher as a vacuum cleaner passes through its trajectory and returns to the charging station.

In order to be economically profitable, one robot must serve several yards. To invent and introduce special feeders is also expensive and difficult. First, re-equip the farm is expensive, because you have to do major repairs. Secondly, in the courtyards a lot of free space is required - at least to drive a tractor. Therefore, a robot is a simple and seamless solution.

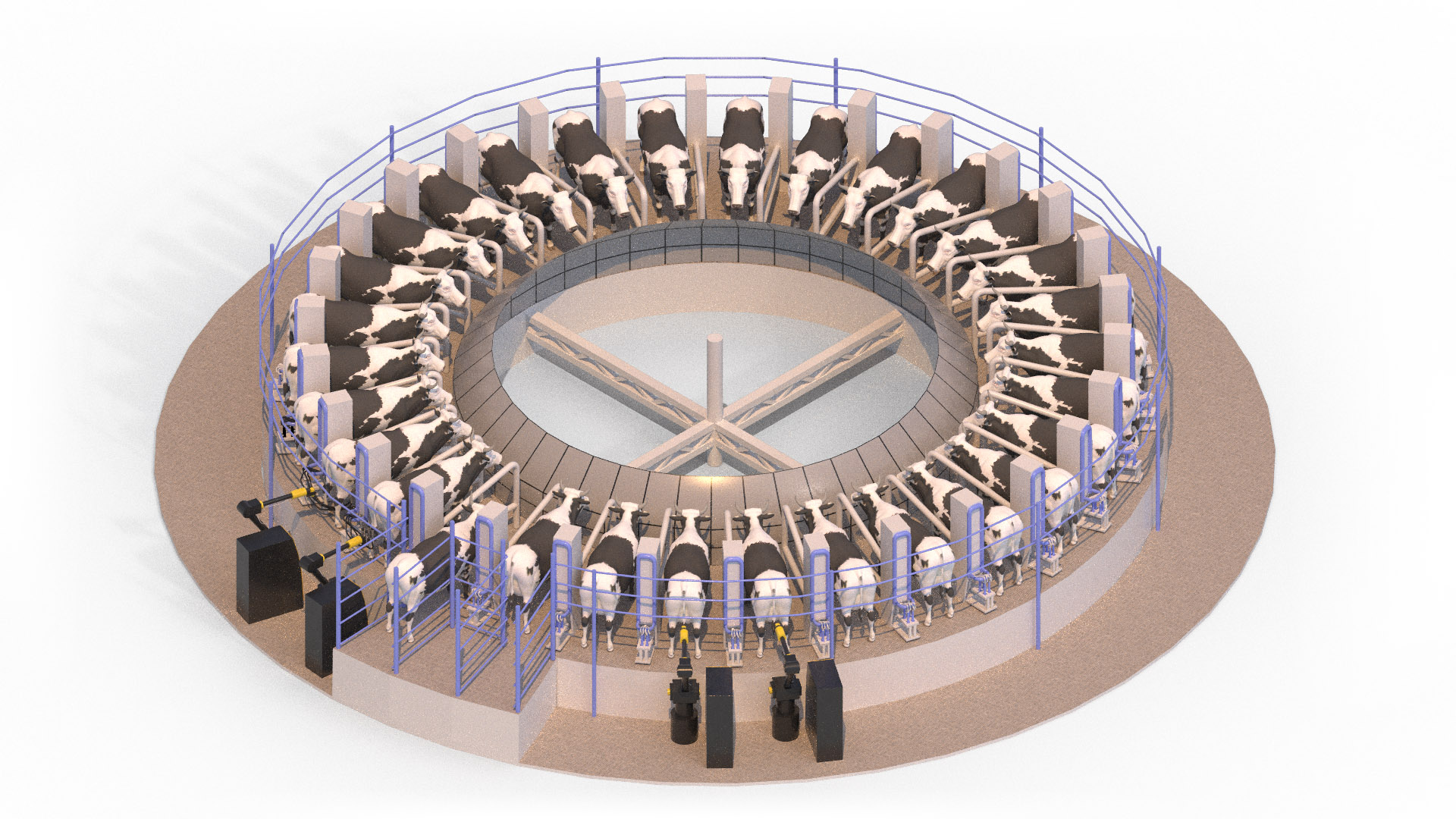

Robot carousel

There are special milking halls, usually they are called carousels. This is a huge roter, where there are twenty to forty cows. It slowly rotates, and there are operators in a circle. First, they clean the udder, put on and take off the devices. But they do it rather slowly, and the carousel is often idle.

It is impossible to completely replace these carousels with robotic ones now - it is very expensive. We make manipulators that can be installed on any type of carousel, and this will accelerate it very much - by thirty percent. Already with this acceleration, you can greatly increase the livestock and the number of cows on the farm.

Diet study

Now they are trying to feed the cows according to the theory of balancing. Each cow per liter of milk needs a certain amount of nutrients, kilojoules of energy, protein, fat. But the features of each cow are not taken into account at all. It is like feeding each person like a middle-aged man about eighty meters tall, as if everyone has the same metabolism.

We make a system that analyzes how the cow responded to different components, how much milk it gave and what quality it was. Based on this, we collect the current correct diet for all components.

We simply take the maximum amount of input about how the cows were fed before, what energy values each component had. We try to build a diet not for maximum milk yield, but for maximum profitability of the enterprise. Each component has its own cost, plus we know how much a liter costs, and we want to find a balance when a cow gives a lot of milk, but its cost is quite low.

The cow gives per year up to 13 thousand liters. But with such a liter worth, for example, 25 rubles. If you make a ration for eight and a half thousand liters, then the cost may be about 12 rubles, and the marginality is much higher than in the variant with the maximization of milk yield. A model is needed to find a balance.

But there are limitations in testing that are easy to ignore. Cows cannot be removed and components added quickly, because they produce enzymes in the stomach that are responsible for the decomposition of, for example, wheat. And the new components will not be digested at first, if you introduce them sharply. A person, by the way, works the same way. When we eat the same food, we digest it very well.

Investments and state attitudes

At that time I had my own funds. We first lived on them. These were very dark times. Sometimes it was impossible to pay any wages at all. One guy had a loan for a car, and at the beginning of the month I threw 12 thousand on the card so that he would pay the bank. Then it turned out to attract money, we became finalists at Statrtup Village in Skolkovo, it became easier.

At the same time we became residents in Skolkovo, because I tried to pay a white salary. Skolkovo gave tax preferences for this, plus we hoped to get grants. But there is a peculiar gap. In order to receive a grant for the first product in Skolkovo, the product should already have money. How to overcome this, when there is no money and there is a desire to do - it is not clear.

Now, I think we still have at least six months until the moment when we start selling robots and this will all turn into a working business. The term is tied to the specifics of working with iron. He has a long production cycle, testing, certification. But now we well know all the largest agroholdings, all the heads of these agroholdings, we all maintain communication with all. I hope there will be no more serious problems.

Of course everyone has conservatism. But here we must not tell, but show. Therefore, we are making the first courtyard in our house so that we can take it by the hand and show it - this is the robot, this is how it milks, this is its economy.

We believe there are many prerequisites to deal with our project. The first is government support. Robots are subsidized, they have leases, a bunch of tax preferences. The state supports the transition to agricultural robotization. There are programs for which the state does almost everything so that you can buy to put yourself robots.

The problem is that people do not want to live in the village. The village is imperfect as a place of life, it is impossible to build a normal infrastructure there. Robotization is the way out.

Of course, when the company costs 20 robots, they also need specialists who will serve them. Robotization does not remove jobs, it increases the efficiency of the enterprise. Usually on the site of employees who were engaged in milking, others appear - those who interact with robots. We have chosen a few good agricultural colleges in which we want to open departments where they will teach people how to handle robots. That is, together with the sale of robots, we will give work to people.

My parents are the greatest skeptics of all and the greatest support at the same time. Previously, they didn’t ask me what I was doing, all the meetings and meetings - the work in the business is strange, it really consists of some meetings. At first they joked about it. But the level of seriousness of the meetings kept growing, the people we met with were getting steeper and more serious. And gradually skepticism was gone. There was only confidence that everything will turn out.